Plaster front on polystyrene foam or foam

Lining the exterior walls with polystyrene is one of the simplest and most economical methods of insulation. But this material is very unstable to mechanical damage, exposure to sunlight and moisture.

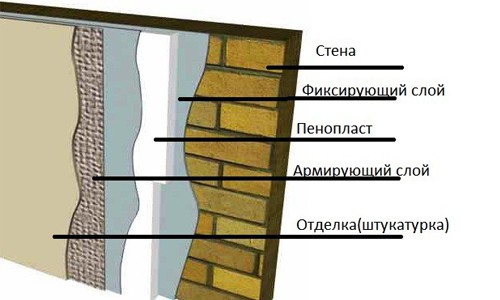

In addition, even small gaps between individual sheets significantly reduce the effectiveness of thermal insulation, and the appearance of the building is not admired. All these disadvantages can be eliminated by facade plastering, designed to protect the insulation layer, level the surface and prepare it for subsequent decorative decoration.

The content of the article

Preparation for work

To plaster the facade wall finished with polystyrene or foam plastic (see Foam facade decoration: how to do it), you need to buy a suitable mixture and other necessary materials and tools, prepare the surface for decoration.

How to plaster foam

The material in question has a very smooth and even surface. This is convenient for installation, but causes some problems during subsequent finishing: not every mixture will adhere to it reliably. Therefore, it is advisable to choose facade plasters for foam, designed specifically for such surfaces.

Experienced builders recommend mixtures of such well-known brands as Ekomiks and Ceresit, but in general any plaster that has good adhesion to polystyrene materials will do. The main thing is not to mix compositions of different brands and manufacturers, to use the same mixture over the entire area.

At the same time, pay attention to the fact that some manufacturers offer different compositions for sticking foam onto the base and to create a protective layer. And others produce universal mixtures suitable for any type of work. If you want to save money, it is better to choose a station wagon.

It is important. Do-it-yourself plastering can only be done with insulation that is glued to the wall and fixed with wall plugs and umbrellas. If the foam plates are embedded in the cells of the frame, another method of facade decoration is chosen - cladding with siding, lining or other materials.

Of course, the selected mixture should have such properties as strength, moisture and frost resistance, especially if the facades are planned to be painted, and not covered with decorative plaster. It should be on a cement, cement-polymer or polymer basis.

The price of polymer compositions is quite high, but they are durable, easy to apply and do not crack when dried.

The amount of plaster is calculated based on the consumption of 9-10 kg per square meter. Of these, 3.5-4 kg will be required for gluing the reinforcing mesh, 5.5-6 kg - for creating a leveling layer.

Materials and Tools

In addition to the plaster itself, you will definitely need a reinforcing mesh. It will strengthen the surface and enhance the adhesion of the leveling mixture to the base.

Note! When using cement plaster, the mesh should be alkali-resistant.

The smaller the mesh cells, the smoother, stronger and better the protective layer is obtained, the larger they are, the easier it is to stick, since the solution easily penetrates through the mesh. The optimal density is 140-160 g / m2 or a mesh size of 5 mm.

Also take care of the availability of the following tools:

- A set of spatulas (narrow for a set of mortar and wide for application);

- Large capacity for preparing a plaster mixture;

- Drill and mixer nozzle;

- Primer roller;

- Grater with an abrasive cloth.

Tip. The instruction for the production of works does not provide for the use of fasteners for the mesh, but just in case, prepare a few screws if you have little experience in such matters. When the glue seizes a little and the net stops sliding, they can be unscrewed.

Styrofoam Plaster Technology

Before plastering the facade from polystyrene foam, it is necessary to seal the joints between the sheets with assembly foam, wait for it to dry and cut off the excess with a sharp knife. If the slabs were attached with “umbrellas”, make sure that their hats do not protrude much above the surface: since the plaster is applied in a thin layer, it will be difficult to level it.

Then the surface is dusted off and primed (see Primer walls and all for that matter) to increase adhesive properties. Further work is carried out in two stages: reinforcement and leveling.

Plaster, if it is not a ready-to-use polymer mixture, is prepared immediately before starting work in small batches, since it quickly loses its plasticity.

Facade reinforcement with stucco mesh

You can stick a grid in two ways:

- Putting it on the treated area and spreading the solution from above. It will penetrate through the cells, gluing the mesh to the base. This is quite difficult to do alone, since one hand will have to hold the grid, and the second to scoop the solution and work with a spatula. Here temporary fasteners may come in handy;

- First, apply the solution to the wall, then apply a mesh to it, pressing it into the glue with a spatula.

In any case, the corners of the building, door and window slopes, and then the planes are first glued.

It is done like this:

- To reinforce corners, the grid is cut into strips 30-40 cm wide and about a meter long or in the size of the openings. Before gluing, it bends in the middle with the application of force to form a rib.

- Regardless of the method of reinforcement, the solution is applied to the surface with a thin layer of up to 3-4 mm, the mesh is pressed into it by movements of the spatula from the angle down and to the sides. Moreover, at the edges should remain strips of 2-5 cm, free of glue for docking with the next strip of mesh.

- When finished with the corners, cut the net from the roll into pieces about one meter long. It is more difficult to mount a larger size; you may not have time to smooth the canvas before the solution dries.

- It is applied to the wall with a wide spatula with a strip equal to a section of the grid minus a few centimeters at the edges for joining. The mesh is overlapped with an already fixed strip and is smoothed with the same trowel with the same spatula from top to bottom from the center to the sides. In the same way as it is done when decal wallpaper.

As a result of your actions, the solution will be squeezed out through the cells, and the mesh will be pressed into the glue layer. The extruded solution is evenly distributed over the surface, hiding the mesh completely.

If necessary, it can be added from the tank. Other stripes are glued in the same way.

When the plaster dries, which, depending on humidity and air temperature, takes from several hours to a day, it must be wiped with a plastic grater with sandpaper to eliminate bumps and obvious bumps. This is done in a circular motion with little effort.

Surface alignment

The next step is to apply a leveling layer. He must hide all defects of the reinforcing layer, completely hiding the mesh and creating the basis for facade decoration.

This work is no different from the plastering of concrete or brick walls, it is carried out with a spatula, but the layer should not be thick, and the joints of the treated areas should be offset relative to the joints of the mesh.

Particularly carefully and accurately performed facade plaster on the foam for painting. You need to try to make the walls as smooth and even as possible, since paint can highlight defects.

The surface is brought to an ideal state with the help of a grout, which should be started no earlier than in a day, when the solution gains the necessary strength.

Note. Too tighten the grout, too, is not worth it. After 3-4 days, you will have to make a lot more effort to sand a very hardened surface.

If the textured decorative facade stucco on the foam is selected as the finish, you can not strive for the ideal. But nevertheless, hollows and irregularities should not be very obvious, and their depth should exceed the grain size of the decorative mixture by more than 2-3 times.

Before applying the finish coating, the plastered walls are primed. A homogeneous liquid primer is selected for painting, and a mixture with the addition of quartz sand is selected for the textured plaster. It gives the surface a roughness, which contributes to better adhesion of materials.

Conclusion

The technology of plastering facades insulated with foam is well shown in the video in this article. If you decide to do this work yourself, without using the services of hired workers, be sure to look it carefully.