We prepare ourselves a mortar for lime plaster

Mortar mortar for plaster is used by masters quite often. This is a fairly simple composition to prepare, which has excellent qualities.

Today we will look at how to make a lime mortar for plaster. You will also get acquainted with different compositions, because for each type of work you need your own. Also on the video in this article, get acquainted with the cooking options.

The content of the article

What is attractive lime composition

The lime plaster solution is not suitable in all cases, so let's get to know it better:

- First of all, I would like to note that good refractory qualities and heat-insulating qualities are characteristic of plaster, it’s easy to work with, it is elastic.

- Wooden walls covered with this plaster (see How to plaster a wooden wall), not terrible rodents. I would also like to add environmental cleanliness. She will breathe, and when driving in nails she will not crack. Due to the high alkalinity of lime, mold and fungus will not appear.

- The plastering of the walls with lime mortar is easy and evenly distributed on the plane.

- Microcracks do not form on it.

- It is applied to almost any base plane.

- When applying the layers, they do not peel off, the bonding is quite strong.

But the composition has its drawbacks:

- The composition of the lime mortar for plaster begins to float a little after a day. This is due to the fact that lime hardens more slowly than cement or gypsum. But this drawback is eliminated simply. The first layer is allowed to dry completely and only then reapply.

- It also hardens much longer than the cement composition.

We prepare a solution of lime

How to prepare a lime mortar for plaster now we will consider in more detail. A mixture of sand and slaked lime, in a ratio of one to two, one to three, one to four or one to five - this is a lime mortar.

The amount of sand is affected by the concentration of lime. So that the solution does not stick strongly to the trowel, you need to add a small amount of sand to reduce fat content. To increase the volume of lime is necessary in the case when the mass does not hold on the surface.

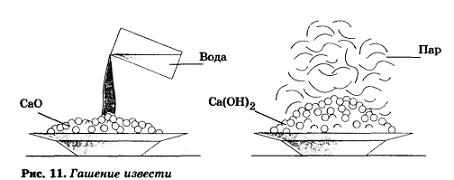

When extinguishing lime, a calcareous body is obtained:

- To do this, you will need any container, only made not of plastic. Pour dry lime into it and pour warm water so that the lumps are completely covered.

- To prevent lime from pouring out during the reaction, you need to cover the container with a lid. When the boil stops, the liquid must be filtered. You can use gauze for this. The lime dough that remains must be left to thicken for one day.

- Take a sieve whose cells are 3 * 3 mm or 5 * 5 mm, pass sand through it. Take some sand and water and add to the container with lime dough. So it will be much easier to stir the composition. As a result, the mass should turn out without lumps, homogeneous.

- The sand that remains must be poured in small quantities, while water must be added. The result should be a solution of medium consistency and normal fluid.

Caution: Such a solution is grasped rather slowly.Therefore, it can be used for two days after its preparation.

How to prepare lime

The main component of all these solutions is building lime. Therefore, it must be used exclusively in an extinguished form in order to exclude chemical reactions when the solution is mixed with water.

Caution: Particles of this material that have not been extinguished will tear or swell the plaster. To repay lime for the purpose of further use, a capacity is needed.

So:

- Lime should be put in this container so that it is completely immersed in water. When steam appears, add a small amount of water. Then mix well. The duration of the process is eight minutes.

- Pour one fourth of the capacity with medium quenching lime. After this, the barrel must be half filled with water. When steam appears, you need to act in a similar way. The duration of the reaction is twenty-five minutes.

- With the help of water, the slowly extinguishing lime is moistened after filling. The material is destroyed, its temperature rises, and the volume increases three times. The reaction lasts for twenty five minutes.

- At the end of the initial quenching, we dilute the lime with water to get a milk of lime. After that, it must be poured into a pre-prepared pit. In this case, it must be filtered through a sieve.

- After a day, lime will need to be covered in sand in a pit. In addition, the earth must be poured on top, the layer thickness should be half a meter.

- For the complete extinction of the material, it will take about twenty days. Milk of milk during this time becomes a dough with a creamy consistency. After that, you can safely collect ready-made lime from the pit for the preparation of various solutions.

Lime plaster. Views

I would like to note that materials such as clay, cement and gypsum are those materials with which lime is well combined. Thanks to this, you can get other types of plasters, the basis of which is lime. Moreover, their properties are much better.

Lime-gypsum plaster

Plaster lime mortar can be made with the addition of gypsum. It is quite durable, the hardening process is much faster, unlike ordinary lime plaster.

- It is not used much for exterior wall plastering. Most often it is used for interior decoration. In this case, humidity should be normal.

- Thanks to gypsum, work accelerates when hardening. This is due to the fact that it sets in five minutes, and after half an hour completely hardens.

- It is recommended for decoration of rooms with humidity up to 60 percent.

- Masters do not recommend using it for finishing a concrete plane.

Attention: Because of this, it is not necessary to prepare the mixture in large volumes - more than five liters. And novice masters are not recommended to work with solutions that contain gypsum.

We prepare a lime-gypsum mortar

For preparation, you will need such components: three or four parts of a mortar and one part of gypsum.

So:

- First of all, you should prepare a regular lime solution. Remove three liters of solution from the container. In this place you need to pour gypsum, then pour water and stir.

- The solution that has been removed must now be returned and mixed well. This should be done no more than three minutes. If necessary, you can add water. The solution must be used within six minutes.

Attention: I would like to note that it is much easier to apply a liquid solution, since it sets better, it is stronger.

Composition is lime-clay

For the manufacture of lime-clay plaster you need a solution consisting of lime and clay dough. It is necessary to use a proportion of zero point five to one, and three to six parts of sand.

The production of clay and lime dough is almost the same. You need to take clay powder or clay, and fill it all with water. The mixture should be passed through a sieve after one or two days. In this case, a plastic material is obtained.

We prepare a lime-clay mortar

Preparation is as follows:

- It is necessary to mix clay or lime dough. Then you need to add a little water to the mixture. Stir well. So that the solution does not stick strongly to the oar, you need to add a small amount of sand. If vice versa, then, therefore, reduce.

- Clay mortar has many advantages, and one of them is environmental friendliness and affordable cost. Walls are very rarely plastered with clay, as it is not strong enough.

- To increase the strength of the clay solution, some components were added to the solution earlier, such as shavings, sawdust, or straw. Today, others add materials, such as gypsum, cement or lime.

Lime-cement plaster

It is used for interior decoration in buildings in which humidity is increased. In addition, it is used as a basis for ceramic tiles. Thanks to cement, the solution becomes more durable, and thanks to lime, its plasticity increases.

The materials should be used in the following proportions: one part of the lime test, two to five parts of sand and one part of cement.

We prepare a lime-cement mortar

The composition of the stucco lime mortar with the addition of cement is as follows:

- The mixture is made from materials such as dry sand and cement. Hydrated lime is needed, it must be mixed in equal volumes with water and added to the container in which the dry mixture is located. Mix very well, while adding water, and bring to the desired consistency.

- To plaster the walls with lime mortar, it will be more correct to apply three layers. One of the layers, the first is the finish layer. The second layer is applied primer. It is considered the main layer. The third layer is spray.

- To finish was durable and high quality, you need to apply all three layers.

Rules for applying lime formulations

Plastering with lime mortar is done with your own hands, the application process can be as follows:

| Priming | Represents the main layer, up to five centimeters thick.

|

| Spray | It is necessary in order to improve the adhesion of the base of the walls and the layer that is applied.

|

The mortar for lime plaster can be prepared without problems. And its price is not big. You have instructions, it remains only to make a choice. Only for external plaster it is worth choosing a mixture with the addition of cement, it is most acceptable.