Types of plaster for walls: what to choose

Which plaster is better to plaster the walls?

For many, plaster is a building material, which consists of sand and cement, which serves to fill cracks and bumps, align walls when wallpapering, applying paint and other types of coatings. But when added to the composition of the dye, it can become an attractive finish coating of any room. The article will tell you which plaster to choose for walls.

The content of the article

Types and features of plaster

By type of plaster happens:

- Wet or Caplesssubdivided into:

- regular;

- decorative;

- special.

- Dry.

The material for the basis of the mixture can be:

- Cement. It is used for decoration on the outside of the house and for interior cover. The composition is quite durable, they are given a different surface shape. Cement-based dry mix can be used for surfaces used in high humidity rooms or temperature extremes.

Tip: On a surface that strongly absorbs moisture, using foam concrete, silicate brick and similar materials, the base should be primed before coating the cement plaster.

With proper solution preparation, it is possible to avoid the appearance of cracks. After laying cement plaster work can only be continued after 10 days. The same type of plaster used for wall tiles.

- Lime. The mixture is used for finishing work only indoors - it is afraid of moisture from rains. The material is environmentally friendly, has a low cost, is easily applied to the wall. The disadvantage is short-lived.

- Gypsum. It has good heat and sound insulation properties. The main advantage of gypsum-based material is easy to apply (see Gypsum plaster: use technology) It does not require mixing, it is enough to dilute with water in the right proportions. Gypsum is a highly plastic material that fits well on various substrates. After plastering, no cracks appear on the surface. Hardens and dries in a few hours.

Negative characteristics include:

- no resistance to moisture;

- poorly resists mechanical damage.

How to choose the right plaster

Such a coating protects any base from weathering, with its help angles, slopes and walls can be well aligned, they are ready for decoration with wallpaper, painting, tile laying. The result of the work depends on which plaster to choose for the walls. Before choosing plaster for walls, you should get acquainted with its types and features.

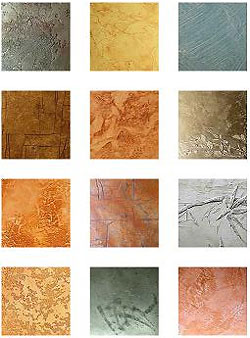

Material in appearance is:

- Structural. Designed to create a kind of furrows. After processing with such a composition, the surface acquires a heterogeneous structure, granular in appearance. The basis of the material is quartz granules. It can be coarse and fine grained. The size of the structural grain can vary from 0.6 to 3.1 millimeters.

- Textured. This is a mineral, structural plaster, reminiscent of a white dough in its raw state, which, after application, can be tinted or coated with paint. Main advantage textured plaster - plasticity, which allows you to create a variety of effects, such as bas-relief, panels. In this case, volumetric plaster on the wall is obtained.

A classic version of textured plaster is an imitation of it for laying stone, bas-reliefs with volumetric patterns, wood bark. After coating the wall, the material acquires the texture of the filler, it looks original, it can hide surface defects.

- "Venetian". This type of plaster is versatile:

- imitates valuable breeds of a stone;

- designers use it to create drawings and other decor on the walls. When performing work, the application must be carried out in several layers, then grout, grind.

The material has excellent decorative characteristics, is easy to clean, repels dirt, which is especially important when the finished wall is waxed or a protective varnish is applied, this coating additionally acquires water-repellent properties and uniform gloss.

- Mineral. The solution is based on crumbs. When decorating the room is used quite often. In addition, it is a persistent, environmentally friendly material, which has a relatively low price.

Among the features of plaster can be distinguished:

- Only manually apply plaster, which has a large filler.

- Do not dilute liquid-type materials with water.

- Water-based plaster has less toxicity, but it is susceptible to negative environmental influences.

- It is difficult to manually apply marble chips.

- Material with high adhesion, due to loss of strength may not be held on the surface.

How surfaces are plastered

Plastering walls with your own hands is a fairly complicated process in technology, which is carried out with some skills. The quality and duration of preservation of the resulting coating directly depend on the correct observance of the technology for performing wall plastering.

The instruction for plastering walls indicates:

- The work must be carried out at a base temperature ranging from (+6 ° C) to (+ 31 ° C), and humidity up to 60%, sometimes the conditions can be slightly different.

- Carefully follow the instructions of the solution manufacturer.

- After each stage of the work, all used tools must be thoroughly washed and cleaned of the solution.

- Each layer after application must necessarily dry well before applying the next.

Tip: The degree of readiness can be determined simply: with a finger, press on the plastered surface, if the material does not crumble, does not slip, you can apply the next layer. If the previous layer has already dried, it must be moistened with water.

Ways wall plaster for different mixtures differ among themselves.

The process of plastering with cement-sand mortar walls includes three stages:

- Spray In this case, the first coating layer has a thickness of 6 to 10 millimeters:

- on stone surfaces - 5 millimeters;

- on the walls of concrete and brick - 9 millimeters, while plastering is performed on a grid, and the mixed mortar has the consistency of sour cream.

Spray is applied only by spraying the solution with a falcon and a trowel on the surface. On the falcon put the right amount of plaster mixture, using a trowel. In this case:

- the falcon should rest one end of it on the container with the solution, and the second rise at an angle of about 30 ° above the container and the solution quickly accumulates the solution;

- when applying the composition to the wall, the falcon leans toward the wall

- from the falcon, the solution is typed with the right edge, you can use the end of the trowel, and then pours on the work surface;

- with a mixture, the wall is covered at different levels, starting from left to right, and after that from right to left;

- after the plaster is applied, the surface should not be leveled.

- Priming. This is the next layer of plaster, the mixture has a pasty consistency.Application is carried out from one to several doses until the surface becomes absolutely even. Plaster mortar in one step is applied with a thickness of up to 10 millimeters.

The soil is poured or spread. The plaster is smeared with a falcon or a half. The solution is first collected and placed on the wall so that the top of the falcon is 50-100 millimeters behind the surface of the wall, and the bottom is pressed against it by the thickness of the entire applied layer with the end of the trowel.

As the falcon moves, the solution covers the surface, and the raised edge of the shield is pressed against it. When using a grater, the mixture is placed on it with a bed, the tool is placed on the wall and is led upwards along it. The graffiti should be with a canvas width of 120 to 200 millimeters, which will allow it to hold more mixture. After applying it in one layer, the surface is leveled with a trowel.

Soil on the surface can be applied in several layers, their number depends on the desired thickness of the plaster layer and on the thickness of the beacons used. The final coating layer is aligned with the rule, which should be moved with sharp zigzag movements from bottom to top.

Leveling with the rule should be repeated several times, gently covering all the depressions in order to obtain a smooth, rough surface. A layer of plaster must be placed with the protruding elements of the beacons on the same level.

- Nakryvka. The thickness of the third layer of plaster coating is from 2 to 4 millimeters, the batch of the composition to the consistency of sour cream.

The coating on the surface is smeared. Then, it is carefully leveled by a grater or rule, by moving the tool from the bottom up, the path is wave-like.

The wall after applying the plaster should have a roughness and serve as the basis for the following layers of putty. This coating eliminates small differences, up to five millimeters, on the wall. The use of a small fraction of filler in it makes it possible to obtain a finished surface smooth, it is easy to sand it with sandpaper.

The process of preparing and applying putty is similar to the process of preparing and coating the plaster mix. Fixing beacons to the surface, in this case, is not required. If paint will be applied to the wall, it should be additionally covered with a thin layer, up to two millimeters, with a finishing putty.

How to plaster a wall with dry plaster composition

Compared to cement-sand mortar, gypsum plaster has several advantages:

- She is more plastic.

- Just applied.

- It dries quickly.

- After coating of gypsum, cracks do not form on the surface.

Tip: Mix dry gypsum with cold water. Hot water contributes to the quick setting of the solution.

Ready plaster for walls is mixed with an electric drill with a mixer. The mixture is prepared in a small container up to 15 liters, with the work of one person, so that it can be worked out until it seizes and becomes unsuitable for further use. The setting time of the gypsum mortar averages from 20 to 60 minutes, which depends on the manufacturer of the dry mix.

When applying gypsum plaster a wide spatula is used, movements are performed in the direction from bottom to top. Gypsum mortar can be applied by spraying. In one go, the coating is applied to the area between two beacons up to 100 centimeters high, then you can start pulling.

For this:

- An aluminum rule is used with beveled edges; its application provides good results.

- The rule is pressed tightly against the beacon guides.

- The tool moves from bottom to top.

- Excess solution is removed and returned to the container with the solution to be reused.

Tip: One alignment usually does not give a satisfactory result.Defects on the surface after coating should be filled with a solution, and the drawing is repeated again.

- Plastering of another surface area is carried out according to the previously described technology.

- Finished sections periodically stretch again from the bottom up. This is due to the fact that gypsum mortar is a fairly plastic material that can simply float under its own weight. This is due to coating the material with too thick a layer of plaster at a time, it can reach 70 millimeters. For large base defects, it is recommended that the coating be applied in several layers, after the previous application has dried.

Tip: Plastered with gypsum mortar surfaces can be putty or smooth over with the same mixture.

- About 50 minutes after stretching, you can start smoothing the plaster layer. According to the technology of the process, smoothing from puttying is no different.

- A small amount of the solution is diluted to the composition of liquid sour cream.

- The mixture is applied to incompletely dried plaster.

- It is rubbed with a wide spatula.

- The operation, if necessary, is repeated several times.

- Smoothing helps to completely eliminate defects that may appear when stretching the plaster.

- At the end of this operation, the surface is slightly hardened and acquires a smooth and glossy appearance.

To save time, if you have the money, you can use a gun for plastering walls.

Tool Advantages:

- A sufficiently high pressure is created inside the gun, which makes it possible to apply plaster on the walls with an even layer. It dries quickly after this, and subsequently does not exfoliate.

- When using a plaster gun, due to the uniformity of the layer, the plaster lasts much longer.

- Coating with a gun allows you to save money, which is associated with the speed of applying the solution, and the process does not take much time.

The gun for plastering surfaces is very simple to use. But there are some recommendations:

- Before starting work, you need to install beacons. How to do this can be seen in the photo.

- Do not immediately do a large number of kneading. After the beginning of the hardening of any solution, it is better to discard them than mix everything again and reuse it, which will increase costs.

- The distance between the cartouche gun and the wall surface should be approximately thirty centimeters.

Subject to the technology and rules for performing plastering of surfaces, it is possible to obtain a high-quality coating and sufficiently durable, regardless of the plaster mix used. Details about the types of plaster and the process of applying it will be shown in the video in this article.