Facade stucco: features of choice and use

Faced with the decoration or restoration of the facade, many fall into a stupor, not knowing what material to prefer, because no matter how trite it may sound, but the facade is the face of the house, and the first impression of guests and passers-by depends on it.

Often the key to decorating becomes the financial component of the issue, so hinged facade systems are swept away, and sooner or later facade textured plaster comes to mind. It is about it that we would like to talk about in this article, as well as to understand why there are so many types of this material and how they differ from each other.

The content of the article

Types of facade plasters

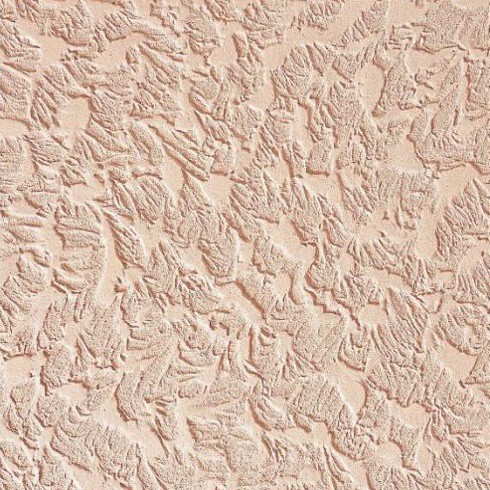

In fact, the textured facade plaster has been known and used for a very long time, but earlier it was limited only to the cement mix and the only texture, popularly called the “fur coat” (see Fur coat plaster: application technology) It is she who is depicted in the photo above, and in this way during the Soviet era, most of the state buildings were decorated.

Times are changing, and with them building materials, the “fur coat” technology is used today, but it looks completely different and all this is thanks to modern stucco mixtures that have come a long way from simple lime to complex polymer compounds.

Modern facade textured plaster is no longer just cement mixed with sand, but a whole range of different materials, each of which has a set of individual qualities and characteristics. But first things first.

Mineral plaster

In fact, it is well-known cement to everyone, but today it comes in the form of a dry finished mixture in bags. For cooking, just add water and mix thoroughly. But if cement mixes met all the requirements of builders and customers, then there would be no need to create other plasters.

And that is why we can highlight several significant disadvantages of such mixtures:

- For decoration, it is necessary to apply paint on top of the plaster, since the cement has an exclusively gray color.

- If you plan to do the work yourself, you need to have certain building skills, without which it will not work to apply a high-quality coating.

- The finished coating, even under a layer of paint, has an unattractive appearance and causes associations with public institutions.

- Has shrinkage when dried and may form cracks on the surface.

If the above nuances for you are not considered minuses, then you can highlight a number of positive points, which, by the way, are slightly more:

- High vapor permeability, which does not allow condensation to accumulate under the coating.

- Complete fire safety. Cement does not burn and does not support combustion.

- Environmental friendliness. Mineral mixtures do not contain chemicals.

- Resistance to weather factors and mechanical influences. In the sun, only paint can burn out, which will have to be updated from time to time.

- Completely neutral to all known solvents and acids.used in construction and repair.

- Not afraid of water, and such a coating can be safely washed.

- Relatively low price in comparison with all species, which will be discussed below.

Acrylic plaster

Facade textured plaster based on acrylic resins is considered to be one of the most attractive, it ideally combines a relatively low cost with high quality finished coatings.

It is from the alkyd plaster mixture that most of the texture patterns are created. Due to its plasticity, it can take any form.

Pros:

- When used together with acrylic primer, the coating is completely resistant to rot and mold.

- A wide selection of colors and textures.

- Relative ease of application.

- No cooking required, since the acrylic plaster is delivered ready-made in plastic buckets, on which detailed instructions for applying are described.

- Moisture resistant and is not washed off even with strong detergents.

- Completely harmless to health, and simple water is used as a solvent.

Minuses:

- Low vapor permeability compared to mineral mixtures.

- It may fade in the sun and lose its color.

- It has poor adhesion with non-mineral bases.

- It costs more than a cement mixture.

Important! Using acrylic-based plaster and primer, it is advisable to buy both components of the same brand. Otherwise, there is no guarantee that the coating will come into contact with the ground.

Silicate Plaster

Silicate textured facade plaster is made on the basis of liquid glass, which has the highest vapor permeability.

Despite the high cost, this type of plaster is often used in construction, as it has a large set of positive qualities:

- Liquid glass coating does not inhibit vapor below the surface and at the same time does not allow it to pass inside.

- It is steady against any whims of the nature and pollution.

- Not afraid of water and detergents.

- Neutral to solvents and acids.

- It has high adhesion to any surfaces other than metal.

- It is plastic and easily takes on a given shape or texture.

- Economical in application.

- It is steady against mechanical influences.

Minuses:

- Narrow color scheme.

- High price.

- The need to use soil only on a silicate basis.

- Difficulty in applying without experience.

Interesting! In most Western countries, the use of silicate-based plasters is prohibited due to the high pH, which it has 11 units, and the standards allow only 9.

Silicone plaster

The most high-quality, but therefore the most expensive option among all the above. Silicone textured facade plaster has a huge list of positive qualities, the listing of which will take more than one page.

With its help, you can create the most intricate patterns and textures. She is completely not afraid of moisture and sunshine. Of the minuses, only high cost and a certain difficulty in applying can be distinguished. The first aspect is an individual indicator, but in order to understand how silicone plaster is applied to a surface, you can watch the video in this article.

Conclusion

To summarize all of the above, we give a small table with the main characteristics of all the described types of plaster.

| Types of plasters | Specifications | |||||

| vapor permeability | moisture resistance | UV resistant | Mechanical damage | contamination | Application difficulty | |

| mineral | average | average | high | average | high | average |

| acrylic | average | average | low | low | high | low |

| silicate | high | high | high | average | low | average |

| silicone | high | high | high | high | low | high |

Based on the indicators given in the table, you can choose the appropriate coverage, taking into account all the individual characteristics of the house and its facade.