Dry plaster gypsum mixture: how to use it correctly

Dry plaster gypsum mix has recently entered the sales market. But she has many fans, because it is not difficult to cook, and installation is not difficult.

Today, dry gypsum plaster mixture will be considered. You will learn its composition and properties. After that, cook it yourself and reduce the cost of decoration. Instructions for manufacturing will be offered and on the video in this article you can visually look at the process of this work.

The content of the article

Main properties, features of use

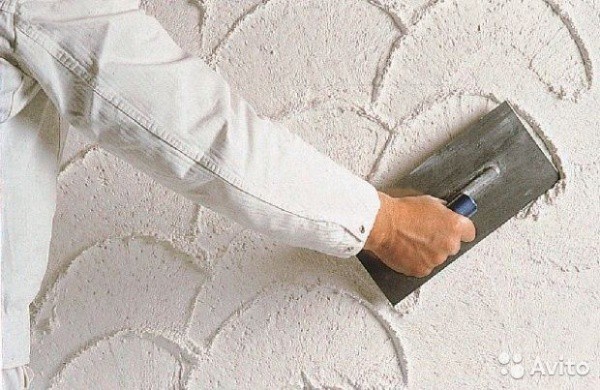

Basically, dry plaster gypsum mixture is used for interior decoration. Gypsum plaster used for preliminary alignment of vertical and horizontal surfaces, immediately before applying a decorative finish.

Attention: At the same time, it is very important that you can use gypsum leveling mixtures only in those rooms in which the moisture level is not more than sixty percent. If this is a large room, and there is a lot of moisture in it, then it is better to use hydrophobic finishes in this case.

So:

- Before starting work, you need to take the fishing line and pull along the diagonal of the plane of application. So you can immediately see the deviations and calculate how much dry powder you need.

- If the layer is large, then it is best to use a building mesh that is mounted on the wall. In this case, the grip will be better.

- Plaster mixtures can be settled in a thick layer. This will not harm the durability of the finish. Therefore, with the help of such mixtures, it is possible to even out significant irregularities and small defects.

- Moreover, such plaster is often used not only in cases when it is necessary to eliminate the relief on certain surfaces. Also, it is often used to level walls with a heaped level.

Than attractive

Dry plaster gypsum mixture has a lot of advantages:

- The price is quite attractiveAnyone can afford it;

- You can cook it yourself without any problems., and it does not take much time;

- You can give almost any form of decoration;

- Finish fits well on any plane, in this matter it is universal;

- Allergens and toxins are completely excluded in this material.therefore it is absolutely safe;

- Finishing will not be required, it will not be spent on it;

- It is light enough and therefore the weight of the wall will not increase much. It is good for load-bearing walls.

- Using the mixture, you can mask and close up a variety of surface defects. In addition, slopes or corners can also be formed.

Attention: The disadvantages of this material include a low level of hydrophobicity, and, consequently, the inability to use plaster in the decoration of the facade.

The composition of the gypsum mixture

Dry gypsum plaster mix has rather simple components:

Caution: Gypsum plaster dry mix is commercially available, but if you have a large amount of work, then it is better to do it yourself. In this case, you will win 50% of the cost of the finished material.

- The main components of standard dry mixes are gypsum and lightweight fillers. Also in their composition they contain modifying additives.It is on them that the quality of the material, the level of its adhesion and many other characteristics depend.

- All manufacturers use different compositions of components in the manufacture, but ready-made mixtures mainly have similar properties that meet certain standards and norms.

- To make dry mixes convenient to store and use, they are delivered in special packaging. Usually, gypsum finishing materials are packaged in specially designed kraft bags. One such bag weighs an average of fifteen or thirty kilograms. Most builders prefer this kind of packaging.

- Store the mixture in a dry room. It is very important that it is well ventilated. In order for the packing to retain its properties, microperfection is done.

- In the case when the humidity of the warehouse exceeds the norm, the mixture becomes unusable, hardens. That is why, before buying factory plasters, check the quality of the purchased material.

Caution: It is very important that the mixture can be stored for six to twelve months. After this, important material properties are lost. In this case, high quality finishes are not guaranteed.

If you do not have a large amount of funds, but you need to finish a large room, then you can not spend money on its purchase, as you can prepare it yourself.

Rules for the preparation of gypsum composition

The dry plaster gypsum mixture is made according to certain rules:

Attention: If you are buying components in the winter, then you should not do this on open trays. The composition freezes and loses its astringent properties. Also give preference to well-known manufacturers and refrain from buying unknown mixtures.

- To begin with, gypsum should be passed through a sieve and make the fraction homogeneous. So you get rid of lumps and debris.

- After this, the powder must be placed in a container and add water in small portions. Mix well until you get a plaster dough.

- In the composition that will turn out, it is necessary to add a lime solution. And again, mix everything thoroughly.

- For kneading, you can use a drill with a nozzle, it will allow you to do everything quickly and the mass will turn out to be as homogeneous as possible.

Attention: I would like to note that you need to mix thoroughly, just do not need to mix for longer than one minute. Otherwise, the solution will lose strength. You can use the prepared solution immediately after preparation.

Cooking options

Dry plaster mix gypsum can do in different ways. This is a slightly different composition and you need to choose the most acceptable one. Everything can be seen in the photo.

First option

To prepare a high-quality and inexpensive mixture, adhere to the following proportions:

- Building plaster - 3 - 4 bags;

- Plaster mix, type ABS (Eco-gypsum or Rotband) - 1 bag;

- Fine sawdust wood - 1 bag.

There is nothing complicated in preparing the mixture:

- Those components that have been listed must be mixed in a dry state until a homogeneous mass is obtained. Then the mixture needs to be poured into bags made of polyethylene, can be in other containers, and stored here.

- Before using the mixture, it must be diluted with a small amount of water. Mix well with a special mixer.

- Factory plaster mixtures in their composition contain special additives that contribute to the regulation of the drying speed of the solution. Thanks to this, working with plaster becomes easier and more convenient.

- Sometimes it happens that a self-prepared solution sets too quickly. To prevent this from happening, add wallpaper glue to its composition.

Attention: It is very important that not every wallpaper glue can be combined with gypsum.I would like to recommend CMC glue - one of the proven options.

- Slaked lime can be added to the composition of the plaster. Thereby. The material will become more ductile. Also, the lime that is used to create the solution has bactericidal properties. Due to this, mold will never appear on the walls.

Second option

To prepare a high-quality gypsum-chalk putty, you will need components such as a solution of wood glue (5%), determine the amount by the consistency of the glue; one kilogram of gypsum and three kilograms of chalk.

- The manufacturing process of the mixture consists of three stages. The first stage is the grinding and mixing of each component until a homogeneous mass is obtained. You can use the capacity for this. A volume of ten liters is quite suitable. And you will also need a hammer drill and nozzles.

- First of all, crushed gypsum and chalk should be mixed. When you get a powder of homogeneous mass, you need to add glue and mix again. The mass should be obtained, without pronounced seals, lumps, light gray in color.

Attention: I would like to note: the putty prepared exactly according to the recipe will dry quickly. Therefore, glue as a binding agent must be added to the dry mixture. It is better to do this before applying to the surface.

- If the mixture is prepared according to this recipe, then it should be used for finishing leveling, and not for roughing. Putty will be applied conveniently and simply (see. How to putty the walls with your own hands, observing all the rules), if cooked correctly.

Third option

Thanks to this recipe, you can prepare a mixture that can finish the painted surface:

- For this you need: one hundred grams of NF-1 driers, two kilograms of gypsum and one kilogram of drying oil.

- It is possible to apply this hard putty when finishing an oriented chipboard. To speed up the drying process, in this case, you can use a drier.

- In the process of preparing the mixture, chalk powder can be used instead of gypsum. The proportions are the same. Thus, the mixture will dry more slowly, moreover, it will be able to maintain its original properties.

Attention: I would like to give one piece of advice. When making plaster mortar, do not forget about personal safety equipment. Use gloves, goggles and a respirator.

Fourth option

By its consistency lime plaster It looks like regular plaster. The only difference is that it dries dry. Because of this, a similar solution must be applied in a thin layer. It should be borne in mind that each of the subsequent layers must be applied only after the previous layer is completely dry.

- To apply the solution was convenient and simple, you need to add gypsum to the lime plaster. The result is a lime-gypsum composition. Its layer dries on average in five minutes. In addition, its distinctive feature is optimal adhesion.

- To get a lime-gypsum mortar, you need to use three parts of the lime mortar and one part of the gypsum powder.

The purchase of finishing materials has a significant impact on the cost of repairs. Significantly save money if you prepare the plaster yourself. Dry plaster gypsum mixture is not difficult and this will help reduce costs.