Foam facade decoration: how to do it

Finishing the facades of private houses with foam is quite common. The issue of warming is relevant in our time.

There are many materials that you can use and one of them is polystyrene. In this article we will consider this type of decoration.

We will determine the correct choice of material and instructions will be given for performing this work. You can watch the video of the facade decoration of the house with polystyrene below.

The content of the article

Pros and cons of polystyrene trim

Like any type of finish, this one has its advantages and disadvantages to be reckoned with. Let's immediately decide what type of structure it is suitable for, and where it should not be applied.

Advantages

First, let's see what can attract in this decoration:

- Price, this indicator is quite attractive and much lower than some materials for the decoration of facades;

- The thermal conductivity index is also at an altitude. It is worth saying that at any low temperature the foam does not freeze, this speaks for itself. Not susceptible to temperature extremes;

- This material is not exposed to moisture and does not need to do vapor barrier;

- This finish is quite durable and will last for many years;

- Not a complicated installation, which is quite possible to do with your own hands and without outside help. This will significantly reduce the cost of all work;

- Not subject to decay.

disadvantages

Now let's move on to the shortcomings, which also exist:

- The biggest disadvantages include the possibility of penetration of rodents. Not even penetration, but life.

They settle perfectly in polystyrene foam and you understand that they are quite difficult to remove; - At high temperatures, the material is toxic and gives off an odor that is harmful to human health.

Foam home decoration

Finishing the facade of the building with polystyrene is not such a difficult task, but it also requires preparation and the correct execution of the work. Here, everything can be divided into several stages, each of which is important.

We will need

For continuous work, you will need to prepare everything in advance:

- Polyfoam or expanded polystyrene. The quantity is determined by area;

- Primer for exterior surfaces;

- Glue for plates or polyurethane foam;

- Profile for the bottom row, which should be selected depending on the width of the foam;

- The grid is reinforced, it should be correctly calculated. Do not forget that the connection of the paintings is not done in a joint, but is overlapped;

- To perform the fastening you need a hammer drill;

- To grout, get a grater.

We prepare the walls

This will be the first step in completing the work. Everyone knows that the base plane is important and properly prepared it will only improve insulation and durability will depend on it.

So:

- We clean the external surface of the room from the old coating. Remove old paint and whitewash.

To do this, use a brush for metal; - Now do a look at the likelihood of peeling off the old coating. If it is, then we carry out the removal with a hammer and a chisel.

We remove all the exterior trim elements, nothing should bother us;

Attention: Polyfoam is attached close to the wall, so we pay attention to the plane of installation. If there are bulges more than two cm. Then they should be removed with a hammer.

- After that, it is worth treating the surface with an antifungal antiseptic, which is available on the market.If you do not have manifestations of the fungus, it should still be done as a preventative measure;

- Next, we need to determine the zero point, this is the line from which the installation will be carried out. It will determine the appearance of the structure and will not allow condensation to accumulate in the room:

- We put on the wall a risk that should overlap the floor level in the room;

Attention: If you do not correctly determine the zero point and do not start fixing the foam, then dampness will begin to accumulate in the room, humidity will increase, an unpleasant odor will occur. This will cause fungus and mold.

- Now we transfer this mark to other walls of the room. We should get a solid line around the whole house.

It should be completely parallel to the ground. For this work, it is best to use the hydraulic level, which you should buy or make yourself.

It is with this tool that you can do the job most efficiently. Move the mark; - Now we need to connect the marks correctly. To do this, use kapron thread and just beat off the level.

Now we have a clear line to begin work.

Foam Mount

This is a crucial issue that should be addressed comprehensively. After all, after installation, the lining of the plane will also be made, and after that the whole product must qualitatively fulfill its functions.

Attention: It should be known, many do warming not with foam, but with foam. It is fundamentally possible to say the same thing.

Only in the second option is it necessary to properly prepare the material for the work. It has a smooth surface that does not contribute to high-quality bonding.

Therefore, before making the connection, the sheets should be processed on the side of attachment with a needle roller and this will improve the connection.

So:

- The base line should be attached along the drawn line. She is most suitable for this work, and will protect against the penetration of rodents from the bottom.

It is also possible to make edging with a starting metal profile and a wooden beam;

Attention: If you use wood in the construction, then before starting fastening, you should pre-process the parts with antiseptics, which can be purchased at retail. This will protect the material from mold and mildew.

Extend the life of the entire product.

- We cut the parts to the desired size and fasten. To do this, make holes in the plane using a punch and make a connection using dowels.

Do not use the expansion bolt shield from sets, they will not provide high-quality connection. Buy retail plastic dummies and self-tapping screws a couple of mm more from the hole section.

Then you get a reliable and tough grip; - Now do the foam mounting. For this, special glue and plastic fungi are used, which subsequently make additional fastening;

- Facade decoration start doing from the bottom row. We apply the adhesive mixture on the surface of the foam and then apply it to the plane and press;

- We make a hole with a perforator and make a connection using a plastic fungus. There must be at least five such attachment points;

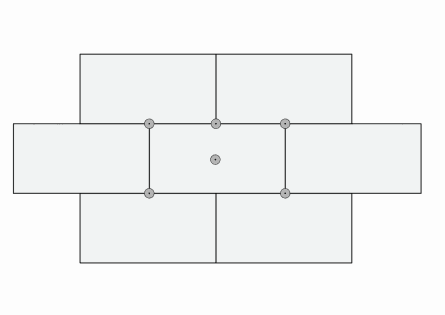

- Fastening of the foam panels should be done in a checkerboard pattern. This will ensure reliable mounting;

- After the parts have solidified completely, welds should be processed. To do this, they are treated with polyurethane foam.

During the work, you should listen to the advice of specialists that they give on this work:

- If the seam is up to five mm, then it should be foamed. If more then it is better to apply a foam insert;

- If on the surface there are irregularities in excess of 5 mm, then they should be removed using a polystyrene grater;

- If you apply the installation of foam in two layers, then the second should not fall on the seam of the previous one. With this installation, the seam can be left without foam.

Apply plaster

After attaching the foam, we need to make the lining of the material on the outer plane, with which we will practically complete the work.

So:

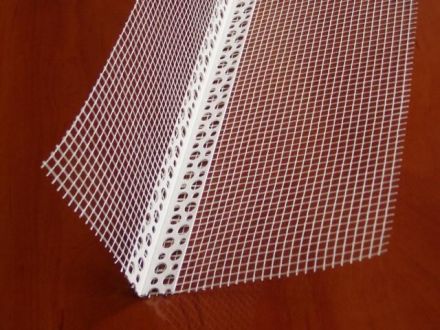

- For plastering, a building mesh is used. It can also be attached to glue and this should first be done and after complete drying, the plaster is already beginning to be applied.

Some fasten it with plaster immediately. In both cases, it is necessary to make the edges of the grid not in the joint, but in the overlap, which is done on the order of 10 cm. - In the corner, a special reinforced corner should be applied, which will make the angle less susceptible to mechanical stress and perfectly even.

- After installing the mesh, the surface dates should dry out and after that apply the finish layer and after it has completely dried, a primer layer is applied, which is subsequently painted.

Facade decoration Styrofoam made successfully. In the photo you can see the progress of the work.

The most important thing is to make good forests so that it is comfortable to work and not to rush.