Styrofoam paint: which can be used

Foam painting is quite an important point in the issue of finishing. Indeed, among the variety of materials involved in the construction and repair of buildings, foam products have an impressive range of applications. Indeed, due to the porous structure, the foam can be used as a soundproofing material for the decoration of interior partitions and walls, as well as for inside finishing and decorative work.

How to paint polystyrene with paint, we will consider today. Also on the video in this article and photo you can see the additional information you need.

The content of the article

Polystyrene painting rules

Expanded polystyrene is a subspecies of polystyrene having a more compacted and closed cellular structure that perfectly performs the heat-insulating function, and therefore it is universally used for insulation of external walls and building facades (see. How is the insulation of the walls with polystyrene foam done outside).

The most characteristic foam materials presented today in the construction market are:

- Styrofoam and polystyrene ceiling tiles;

- Foam baseboards;

- Styrofoam Decor Elements;

- Expanded polystyrene blocks for outdoor use.

Every year, the production technology of this material is improved to increase the level of environmental friendliness and fire safety. Equally important is given to the needs of consumers to solve problems related to the refinement of the interior of the house.

However, foam elements and structures, regardless of their field of application, have characteristic compositional features that require timely and high-quality surface painting (treatment).

Why polystyrene is painted

Despite the ease and convenience of working with polystyrene foam, which ensures the comfort of residential buildings, surface painting is due to a number of reasons presented below.

So:

- Design solution. Room decoration with ceiling tiles (see Ceiling cladding: choice and characteristics) or skirting boards for decorating is not always limited to just the classic white color. The need to change the original color of the above materials may be due to the desire to give the interior of the room a more concise and aesthetic look. In addition, staining is an alternative to the complete replacement of a product that needs to be updated if it faded or was damaged over time.

- Elimination of surface irregularities. A negative property of the foam is its fragility. After staining, possible dents from inaccurate installation and other defects, as well as joints between products will become less noticeable.

- Protection against negative environmental influences. A special detrimental effect on the surface of foam materials is provided by sunlight. It is the effect of ultraviolet radiation on unpainted surfaces that can lead to the premature appearance of yellowness. Sudden changes in temperature are tested on the strength of the foam, which is used as a heater of external walls. Covering the surface of the blocks with protective solutions can provide additional protection of the material from destruction for reliable and long-term operation of the building.

Obviously, the foam is an affordable material, the disadvantages of which are very easy to level using a simple surface painting procedure. The main nuance that you need to pay attention to will be the acquisition of a suitable solution for staining.

We make a choice of dye for work

The coloring of the foam is done with various dyes. There are a lot of them. But there are two main types. So what kind of paint to paint the foam should be decided immediately and make a choice immediately from two options:

| For exterior surfaces | These dyes are distinguished by their positive response to environmental influences. These include facade paint on polystyrene foam and another, which will be affected by increased humidity and temperature extremes. Thinking how to color the foam for fishing will give preference to this particular dye. |

| For interior surfaces | This composition does not tolerate high humidity and low temperatures. So the instructions for the dye should be carefully read (see Types of paints for interior work: consider in detail). |

Whatever the reasons for processing the foam surface, it is important to remember that the ill-considered use of inappropriate chemical composition of paints and solutions can adversely affect the final result of all construction and finishing work.

Caution: Organic components in the paintwork such as acetone, toluene or ethyl acetate can soften and then completely dissolve the foam product. Therefore, when choosing a future coating, a careful study of the composition will ensure a satisfactory quality of surface treatment.

- For example, adhesion plays an important role in the strength of a polystyrene foam coating (polystyrene foam or PSB). The property of solutions at the molecular level to fully interact with polystyrene material, forming a protective layer, greatly increases the reliability of such a coating.

- By the way, the increased resistance of coloring materials to insolation and other factors related to the microclimate will provide an aesthetic component. Foam products will retain a neat appearance for a long time.

Given the above requirements, it is most advisable to opt for the following paintwork products for the treatment of foam surfaces:

- Acrylic based paints;

- Water-based paints.

The popularity of acrylic and water based paints is due to various factors.

- The acrylic base protects foam products from dust and moisture, provides resistance to temperature extremes, has no unpleasant odor and dries quickly. Another important plus was the widest choice of a palette of colors and shades, which when applied do not form cracks. However, such coatings are not durable and require periodic updates.

- As for the water-based base, due to its properties, painting the surface does not require special painting skills, due to the consistency that is convenient for applying. It is important that water based paints are harmless to health. Therefore, both types of paints and varnishes are worthy of use when conducting internal repairs.

For materials based on polystyrene foam used for outdoor work, it is also advisable to use lime water solutions and bitumen mixtures.

Carrying out foam painting indoors

The price of products for processing foam materials varies in a fairly wide price range, which is more dependent on the physicochemical characteristics of the coloring solutions, the manufacturer and the field of application. For example, a liter of acrylic suspension or solution based on a water-based emulsion costs from 20 to 50 rubles.

Higher price, over 50 rubles, for acrylic solutions with improved resistance to external influences. However, they also need to be updated periodically.

For successful do-it-yourself work on coloring foam elements of decor and interior decoration (for example, ceiling tiles and baseboards), it is necessary to carry out a number of consecutive preparatory work:

- Cover furniture and other overall objects with a film in order to avoid their damage;

- To clear the room of small foreign objects;

- Prepare gloves, goggles, a respirator, as well as a hat;

- To clear a surface of a ceiling tile or a plinth of dust and dirt;

- If necessary, fill joints between separate elements with sealant or putty;

- Prepare tools for applying the mortar.

As a coloring solution for intra-finishing work, a suspension of acrylic or water-based coatings are used.

Attention: Their use only when working indoors is associated with a low level of resistance to increased humidity in the room.

- If necessary, additional paints and varnishes are added to the main solution to achieve a certain color solution.

- To obtain high-quality saturated color, the surface should be painted in several layers. The optimum effect will be achieved only with the complete drying of each applied layer. The number of layers depends on the viscosity of the paint material.

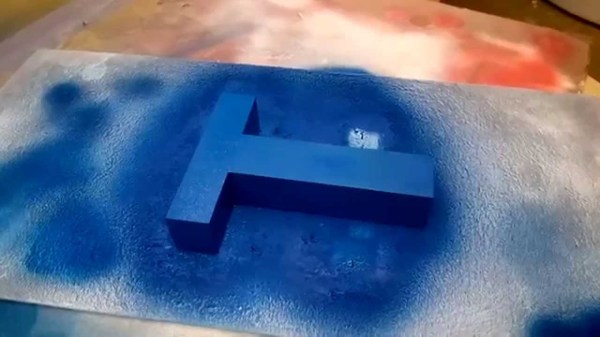

Caution The relief pattern on the ceiling tiles can complicate the work of high-quality painting of the entire surface of the foam product, so the spray gun, if desired, can be a good alternative to the traditional foam roller.

- An exceptionally creative moment in the work on decorating the ceiling of a room can be the fine painting of hotel elements already fully painted in the required color of the ceiling tiles. Of course, it is important to observe the time allotted for the drying of the main coating layer. It is permissible to use gouache and thin brushes to decorate with patterns and ceiling ornaments.

- In general, when working on the ceiling of the room, it is important to pay great attention to accuracy, especially if other finishing work has already been completed.

Attention: Reliable adhesion of ceiling tiles or skirting to the ceiling directly depends on the quality of surface preparation, in particular the implementation of dust removal and leveling measures. The glue used for these purposes should be specialized and made on the basis of polymer components, providing not only reliable fastening, but also the safety of the material itself.

Exterior polystyrene painting

When performing exterior finishing construction works, it is important to remember that the effect of an aggressive environment on the material is amplified many times, therefore the technology for processing polystyrene foam surfaces has its own characteristics.

- Before direct application of a coloring solution to polystyrene foam on the surface of the product, it is imperative to conduct its preparation. To do this, use silicate solutions (the second name is liquid glass). Namely, liquid glass will strengthen the structure of the material and allow more evenly and carefully to apply the paintwork material, which will not be able to violate the integrity of the polystyrene foam.

- It is only important to note that a silicate solution of potassium or sodium, in order to further increase the elasticity, needs to be diluted with water or a soil mixture, followed by thorough mixing before directly applying polystyrene to the surface.

- In addition, putty can be used as a preparatory work before painting, which is applied in a thin layer on the work surface.After drying, the susceptibility of polystyrene foam to destruction even from paint containing organic acids is minimized.

- When plastering the surface, it will be necessary to attach a building mesh. It will be reinforcement and then the solution will hold for a long time and will not exfoliate.

- Before applying the dye, it will be necessary to apply a primer layer and it is better to give preference to deep penetration liquids. And only after complete drying dye is applied.

Attention: Thus, a simple but effective procedure for processing and dyeing materials made on the basis of polystyrene foam and expanded polystyrene will give extra strength, provide reliable protection and allow you to realize the most daring design ideas.

Is it possible to paint polystyrene, and now you know how to paint polystyrene too. The most important thing is not to rush and qualitatively prepare the plane. The durability of the coating will depend on this.