Paints for metal doors

Most often, people choose paint for a metal door in two cases: when they want to save money, and when they are already faced with the purchase of a finished door, which peeled off after a few years. In this article we will analyze in detail the question of how to paint a metal door and describe a number of materials according to the degree of increase in their quality characteristics.

The content of the article

Enamels for metal

The word enamel itself is very generalized and includes a huge range of paints, but not all of them are suitable for painting metal, since they have low adhesion with it, which means they will lose their qualities in a short time. As for enamels for metal, three main brands can be distinguished, each of which has its own set of positive and negative qualities, but first things first.

Gf

In fact, GF is the marking of soils. That is, they are not an independent paint, but are used as a substrate. Such paint for metal doors can only be used if the door itself is not the central entrance, but installed in the backyard or basement, for example.

Enamels labeled with GF have several characteristics:

- Total lack of gloss, since this paint is only the basis, it is specially made matte, and with a rough texture, which improves adhesion with a subsequent layer of paint.

- A small variety of colors, mainly, soils are white or red, since it is on such a surface that you can subsequently see all the unpainted spots.

- Complete non-interaction with nitro-based enamelswhich simply fold when applied to the ground.

SC

Or just nitro enamel. In many private firms, the painting of entrance metal doors occurs precisely with the use of this type of paint.

And there are a number of explanations for this:

- Low price.

- Drying instantly in all weather conditions.

- A high degree of gloss after staining, which, incidentally, leaves very quickly, especially when the door is not in the entrance, but in the street.

- Possibility of applying by any of the available methods, whether it be a roller or a high-pressure spray gun (see How to choose a spray gun and not make a mistake).

Despite these characteristics, enamels marked with NTs are considered the most low-quality and short-lived. This is due to the fact that the paint itself does not penetrate into the metal structure, but simply lays with a thin layer on the surface, that is, there can be no talk of any deep adhesion.

When using the door in outdoor conditions, such a coating will last for a maximum of two years, then the entire door will have to be cleaned and repainted.

Advice! In no case do not work with nitro enamels in closed and unventilated rooms, as they contain toxic substances that can cause significant harm to health.

PF

Undoubtedly, the most famous and widespread type of enamel on metal. Also, this paint is often called pentaphthalic or just oil. It has high adhesion to metal surfaces and is resistant to most types of exposure.

Of course, here it is necessary to pay special attention to the paint manufacturer, since due to its great popularity, on the market you can find many fakes of low quality that do not meet any standards and requirements.

As for the characteristics of PF brand enamels, several can be distinguished:

- High adhesion to metal surfaces.

- It retains glossy gloss for a long time.

- It does not fade in the sun and is completely neutral to ultraviolet radiation.

- It is not afraid of moisture, and in turn is able to protect metal from corrosion.

- Resistant to mechanical stress, PF enamel is not easy to damage even with a sharp and hard object.

Of course, there is a certain set of minuses, and the most basic one is slow drying. Withering of each layer can take up to several days, depending on weather conditions and temperature. Moreover, each layer dries about 30 percent longer than the previous one.

Although, if you decide to carry out work on painting with your own hands, then there should not be any difficulties over time, the more that the better the paint is dried, the longer it will last under operating conditions.

Important! The room in which the door is painted should be as clean as possible, since dust particles flying in the air will settle on the still-frozen paint and spoil its appearance.

Enamel Enhanced Resistance

Such paints are much more expensive than the usual enamels, but this is fully offset by their durability and quality characteristics.

Very often, enamel of increased resistance have in their composition a whole set of different ingredients, due to which, the paint can be applied in any way and in just one layer, and at the same time it will not only not be inferior in quality to multilayer coatings, and even be ahead of them by several orders of magnitude. The range of such paints is quite large, but we will focus only on the most popular brands, which are in high demand, both among ordinary consumers and specialists.

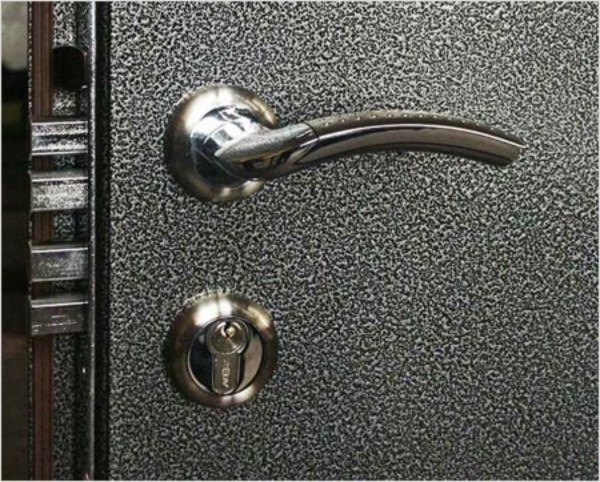

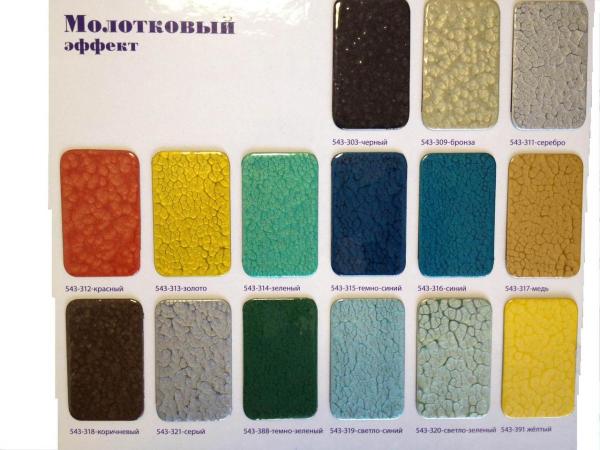

Hammer enamel

Many have met with such a coating, but not everyone knows that this is a hammer enamel. It is named so because after complete drying a characteristic chipped surface is formed, which looks like traces of a blow to a metal with a blacksmith hammer.

Hammer paint is a reliable coating that is not afraid of not water, not ultraviolet rays. It can be applied to any metal surface and in any way convenient for you personally.

The only thing that needs to be noted separately is that when applied with a spray gun, gaps may occur in the coating, so if you paint the door yourself, we recommend that you watch the video in this article, which shows detailed instructions for applying a hammer paint with a spray gun.

As for the positive qualities, in fact there are a lot of them, so we highlight only the most important:

- Painting doors with metal hammer enamel can be done at any temperature, and the drying time of the layer does not exceed 3-4 hours.

- Before painting a metal door with a hammer paint (see How to paint with a hammer paint spray gun), it does not need to be primed or degreased. Simply remove any contaminants and scale from welding.

- A complex texture pattern of hammer paints, performs not only a decorative function, but also reliably hides all the flaws of a metal product.

- The finished coating is very difficult to damage, and this can sometimes be a disadvantage, since it will take a lot of effort to remove the old coating.

- The minimum guarantee for manufacturers of hammer enamels is 25 years, and this, you must admit, is a very weighty argument if you choose how to paint the entrance metal door.

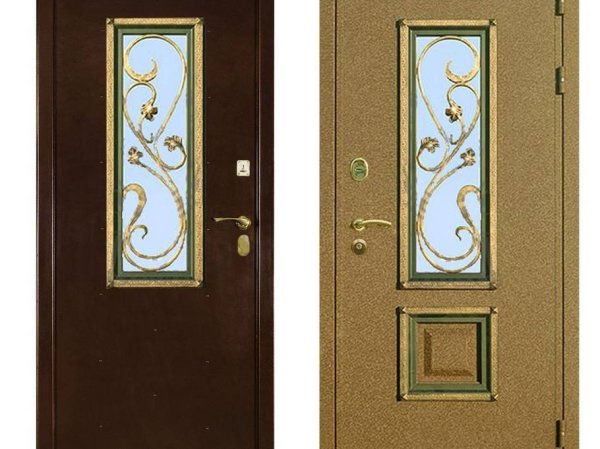

Blacksmith paint

You are unlikely to find this type of dyes in an ordinary hardware store. Such enamels can be found in those who specialize in the production of art forging.

Their main distinguishing feature is the highest resistance to all types of impacts, compared with all the materials described above. It is very difficult to damage such a coating, the paint seems to eat into the metal structure and becomes one with it, and add to this full resistance to moisture and sunlight, we get the perfect paint to cover the entrance metal door.

If we talk about the minuses, then the cost of all the components of this paint stands out, and it is applied in at least two layers and additional decoration with a third layer is possible:

- Special primer with a characteristic rough structure and bright yellow color. The presence of such a color on the ground is no coincidence, firstly, the master can clearly see where the product has not stained, and secondly, when applying black paint, you can be sure that no corner will go unnoticed.

- The paint itself. It is applied to well-dried soil using a high-pressure spray gun, as the paint has a very thick consistency, and it is not recommended to dilute it.

- Decorative patina, which in itself is not a coating, but acts only as a decorator. Thin patina strokes on the painted surface give the metal a look of natural old age and nobility.

Important! There are very few manufacturers of blacksmith paints, as well as shops selling them, so always ask for certificates of conformity and quality so as not to run into a low-quality fake.

Powder Polymers

Powder coated metal doors (see How is powder coating of metal products carried out?), the process is very complex and time-consuming, of course, it can be done in a garage, but for this you will definitely need special expensive equipment, which is not practical to buy for the sake of a one-time operation.

It is with powder polymers that most of the metal doors manufactured by large companies are covered, and in most, it is this coating that affects the final cost of the product. To initially dispel all dreams of powder coating at home, we briefly describe the entire bearing process, which consists of several stages.

Stage One - Painting

Before painting a metal door, it is thoroughly cleaned and placed in a special sterile chamber equipped with powerful hoods and traps for excess paint.

The product is grounded while the spray gun is connected to the network and has a positive electric charge. Thus, at the time of applying the powder paint, a small circuit of the network occurs, and the paint penetrates the molecular structure of the metal, becoming one with it.

Due to the density of the paint, the whole process is very slow, and it can take up to several hours to cover one door with a master. After the paint is applied, the product is moved to another chamber.

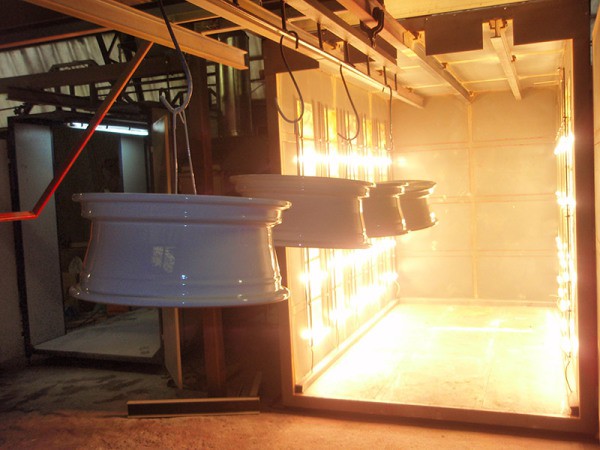

Polymerization

This is the second stage of painting, when in another chamber the product is heated to a high temperature, as a result of which the so-called polymerization process begins, that is, the coating acquires its own unique appearance.

In fact, the paint is applied in three layers:

- Priming.

- Paint.

- Lacquer.

And after each layer, the product is transferred to the polymerization chamber and kept there for the required time at a temperature of 160 to 200 degrees, depending on the purpose of the coating and the type of paint. After each warm-up, the camera turns off, and the product itself must cool to room temperature.

As you can see, the process is very complex and time-consuming, and we have not yet dwelled on small details, which are a huge number when working with powder polymers. After completing all the stages of painting, all additional elements are put on the door, and it is sent to the client.

Talking about the advantages of such a coating simply does not make sense, since among all the types described in this article, powder dyes are the most stable and durable, and by the way, today more and more people are trying to paint their cars with these paints, and this also says a lot about the quality of the material. which does not decay and is completely not subject to corrosion.

And in conclusion

If, after reading all the above, the desire to paint the door on your own did not disappear, then everything is in your hands, you can safely collect all the necessary equipment and materials, and get to work. And we, in turn, can only hope that our article was able to fully answer the question of how to paint the entrance metal door, and helped to decide which paint to choose.