How is the insulation of the walls with polystyrene foam done outside

Foam insulation of walls outside is very common. This material will serve as an excellent insulation and its installation can be completely done with your own hands, therefore the cost of the work will be much lower. We will consider how to insulate the outer walls with foam plastic today, you will have complete information, and the video in this article and the photo will help you do everything in a short time.

The content of the article

What is important to know about external insulation

Do-it-yourself insulation of the walls from the outside with foam is quite simple, even a novice can easily cope with it. The essence of the technology is to thoroughly clean the primed surface (see Types of construction primers and their scope), and on the prepared wall butt joints of foam are attached.

In any work, it is important to follow the technology, including insulation with your own hands. Although it is believed that polystyrene is a simple material that does not cause installation difficulties, it also has its own specifics.

To verify the simplicity of its attachment to the surface, it is enough to quickly read the step-by-step technology. But, in addition to the instructions, it is recommended to comprehensively study all aspects of working with polystyrene foam as a heater.

So:

- It is important that the old surface be pretreated, i.e. there are no loose layers of old putty left on it (see How to remove putty from the walls and how much is needed) and other mixtures. Insulation sheets are mounted on a solid and well primed surface.

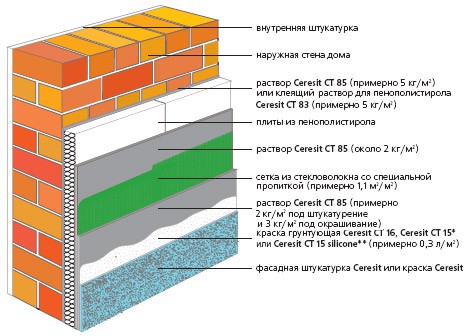

- With foam, they work with a special adhesive composition intended for this insulation. In addition to glue fixing, I fix the sheets at the corners with dowels for decoration - with caps “fungus” or “umbrella”.

- It is necessary to glue the polystyrene carefully so that the composition does not go to the ends, since these smudges and influxes form “cold bridges”.

- The applied insulation is additionally coated with an adhesive to reinforce the mesh. It helps to keep the insulation sheets in a monolithic layer, on top of which a finishing solution is applied.

- The facade, reinforced with reinforcing mesh, is protected from cracking and other defects. Visually, it looks like new for longer.

Attention: The choice of fiberglass mesh is a crucial moment, since it is fixed on an alkaline medium, contributing to the destruction of the reinforcing mesh. Over time, it crumbles into dust, not performing the fastening function in full. The facade reinforcing mesh should contain a special composition that impregnates the fibers, interfering with destructive processes. Do-it-yourself plaster choice for wall insulation with foam

On top of the fixed mesh, the entire exterior wall is primed under the finish plaster or other type of finish.

Please note: The type of finishing plaster affects the quality of the surface and the period of use, and it is important to choose the right one.

The most common mixtures are silicone, mineral (cement-based) and acrylic:

- Cement mixture vapor permeable, it responds well to changing weather conditions. It is suitable for Styrofoam and Styrofoam plastersbut crumbles over time.

- Acrylic mixture forms a denser structure, lasts longer, but does not have a sufficiently high vapor permeability.

- Silicate Plaster “Breathes” and forms a layer resistant to shedding over mineral wool.

Advantages and disadvantages of warming a house with polystyrene foam

Foam insulation of external walls has a large number of advantages in relation to other materials.

Let's take a look at them right away and decide how much this material is suitable in your case:

- The warming method does not require large material costs, but it is quite effective.

- Installation is simple, accessible to everyone.

- External insulation of the facade saves a lot of energy for heating the living room, makes living more comfortable.

- A surface treated with foam sheet is not susceptible to mold or mildew.

- The technology does not require resettlement of residents at home during insulation, there is no need to work on a new surface, it is enough to prepare the wall for the installation of foam.

- In contact, it is noticeable that the technology is effective - the wall seems “warm”, in contrast to the untreated surface. This is because the “freezing point” is located inside the insulation, which extends the life of the building materials from which the concrete wall or brickwork is built.

- Warming with light materials does not burden the foundation, and this method is recommended for buildings on all types of soils.

There are other options for warming the facade of residential buildings, for example, spraying polystyrene foam or laying basalt cotton wool. It is possible to combine methods, especially in apartment buildings, when insulation is carried out on the outer wall and in the entrance.

Comprehensive warming is effective when warming the entire house or entrance, so that energy saving is felt not only in one apartment, but also on the stairwell. This material has its drawbacks.

You must familiarize yourself with them before making a choice:

- Thermal insulation of the walls from the outside with polystyrene foam has a big drawback, it perfectly allows rodents to live in it.

- The plastered surface crumbles over time and requires reconstruction.

- It is recommended to work only at temperatures from + 5 ° C.

Polystyrene insulation rules

How to insulate the wall from the outside with polystyrene will now be considered in order. This work requires compliance with the technology of work and certain rules that will help to obtain a positive result.

Surface preparation for insulation

The technology of insulation of the external walls with foam begins from the base plane. She must be perfect. Brickwork or concrete goods may have curvature, defects, cracks (see How to repair cracks in brick walls) and gaps, therefore, the insulation of the outer wall begins with quality training. Before processing, it is required to make it as even as possible, but small concave places can be left as it was by filling them with glue.

Convex spaces are much more difficult to bring into proper form than the notches. It is not recommended to leave more voids under the insulation sheets - after a small impact or other mechanical impact on the facade, a fragment of the insulation can break or deform.

Attention: The insulation applied to the convex section will easily peel off when exposed. Any differences and irregularities contribute to the fact that the foam will separate. The wall prepared for insulation can have differences within 1-2 cm.

The quality of the facade also has an important role - the surface should not:

- Crumble;

- To crumble;

- Dust;

- Peel off;

- Separated by fragments after the glue.

Caution: It is advisable to clean the old paint coat with a spatula. The wood surface must be well sanded by hand or mechanically sanded.

It is easy to check the readiness for processing the facade:

- Hold it on the wall with your palm, it should be clean and dry, you can immediately process it with a primer.

- If there is a small trace as a whitewash, it is enough to cover the wall and prime.

- Sand (clay, other fractions) crumbles from the wall, the wall will have to be thoroughly cleaned before the primer.

Attention: Some low-quality surfaces, for example, silicate brick with a cement mixture, will gradually crumble, no matter how much they clean. For this option, rough processing is enough to remove what peels off in large fragments, and then putty or plaster with a glue-based mixture. Facade treatment with a fastener with PVA from an airbrush or spray gun is effective.

Insulation Installation

Polyfoam for wall insulation from the outside after fasteners should have a flat plane. There should also be no cavities at the joints. It is immediately worth noting that the external insulation of wooden walls with foam is done in the same way as any surface. Only the foam compound is mainly made with slate nails.

Important: For high-quality insulation of the surface, we fix the sheets so that the joints are in the middle of the fragment, as in the classic brick ligation.

First, fibrous insulation is applied to the gaps. When small cracks are processed, window sills and slopes are prepared, they go on to warm the main surface of the facade.

The most effective method of fixing the foam on the outside with your own hands is to simultaneously fix the plastic parachutes with caps on the corners and center. With this technology, you should not worry about the durability of the processing.

- The insulation is applied from below, that is, the lower layer is laid out from the foundation. It rests on the starting bar (wood, aluminum, corner), which is mounted in a quick way - using a tool, through an equal step. Some masters do this even without a lower side (strap), but with a starting base there will be a more reliable and high-quality installation - there is less likelihood of a heater displacement.

- Without fixing with dowels and the starting plate, the foam sheets will slide down until the glue dries, especially if it is liquid. To guarantee, the bottom row should rely on something, but sometimes enough foundation finishes, which reliably becomes a series of insulation without slipping. A well-soaked surface helps to weight the sheet, which adheres better to the facade. Before final fixing it is necessary to press it.

Attention: It is most convenient to work with two spatulas, wide and narrow scapular. Small adhesive layer is applied on a wide spatula, which is convenient to work on a large plane of the facade. Experts work on a smooth surface with a gear "comb". The wall is defective and filled with the "blotch" method, throwing a foundation with a spatula.

- The glue base is applied to the facade, not foam. It is possible to even out and fill in all the bumps and impregnate a slightly crumbling wall.

- It will not be an error to fill the pits with a mixture where the wall is not well developed. A thin layer of glue applied to the foam does not provide sufficient impregnation of the glued surfaces, and the sheet lags even on small bulges.

- On an ordinary wall without defects, several “frogs” are thrown onto the facade, stretched from the center to the perimeter. It is not necessary to apply the same strokes, provided that they are well leveled. It is important that the surface is worked out as much as possible. The more fully filled the hollows and crevices, the better the insulation of the facade will turn out.

- The most difficult thing is to work on a surface where there are many bulges and irregularities. If possible, they should be beaten or scraped off the foam sheets in the form of these influxes. If the wall has multiple defects, it is fully aligned. On small bulges, the adhesive base is applied in a thin layer, but it is important to fix the corners well with hats.

- If the foam sheets sprawl due to wall irregularities, be sure to fill the voids between them with glue or other filler applied with a “sausage”. It is carefully laid with a small spatula, so that a continuous base is obtained, as when grouting tiles. Pressing the sheets, this basis makes it possible to evenly distribute between the joined sheets.

- We attach a sheet to the treated surface, carefully adjust it to its place and press it. With a little slap of the palm of your hand, we press the foam to its place, aligning the edges under the previous sheet, so that an even edge or side is obtained. It will be the basis for the next insulation belt applied above. And so to the very top of the facade. It must be patted carefully so as not to make dents on the foam sheets. They work especially neatly on irregularities and defects.

- EPSP sheets are sold with a “quarter”, which reduces the cold bridges, goes to the polystyrene with ordinary squares or rectangles. The installation of EPPS will be denser, but it is advisable to additionally roughen it before application, and it will not work to make a cavity under convex walls.

Attention: Do not rush to fix the foam layers. Experts recommend waiting 2-3 days until the glue under the lower layer grabs well, only after that there is further processing. When the insulation is seated and firmly fixed, it is reinforced with a mesh.

Warming the walls with foam from the outside with your own hands is done slowly, most often, along one wall, less often around. This time is enough for the pasted sheets to sit down and adhere securely to the facade. Specialists first stick the insulation, then step by step they nail the edges with hats for final fixation.

Long-term processing of the facade before reinforcing and primer for putty has its drawbacks, especially if you wish by different methods:

- Firstly, you have to align 2 walls at the corners, if the lower bar was of different thicknesses.

- Secondly, the insulation without lower fixation will slip and it will be difficult to stick it higher or somehow displace it.

- Thirdly, it will be necessary to somehow eliminate the bridges of cold.

- Fourth, it is impossible for the polystyrene to overheat in the sun for a long time and soak in the rain, gaining excess moisture. The whole house is more convenient to process along one wall, but it is easier to adjust the edges around the edges.

Attention: If you have to process areas above one floor, it is important to take care of the safety of the stacker and the convenience of processing.

Foam Fixing

After the adhesive base has dried, the sheets are nailed to the facade. A couple of days is enough, depending on the air temperature, to dry the glue. It is necessary to work without crushing the edges, but sometimes it is advisable to apply additional washers if the base crumbles.

- Weather conditions affect the quality of the facade treatment with insulation, so it is important to listen to weather forecasts and not to begin large-scale work before prolonged rains or cooling. To hammer or drill layers on a not quite adhering and dried basis - to risk that the foam will in places depart from the wall.

- Plastic "umbrella" makes a control fixation. A special nail is driven into the sleeve. It is preferable to choose not a metal base, but a plastic one. Preference is not given to the cheapest hats that can be deformed.

- It is better to work with a puncher, drilling holes for fixation. The depth of the holes is better to do a little more than the height of the fungus, to allow the debris falling there to make room for full fixation. The length of the fungus is correlated with the thickness of the insulation, plus 1 cm (to other layers) and an additional 4-5 cm to the wall.

- Experts recommend placing the holes in a certain order - to place the fungi at the junction of the foam, and in the center of the sheet (5 pieces). There may be more latches on the problematic surface, especially with regard to the edges.Although you have to work a lot with a puncher, it’s an additional guarantee of high-quality fastening, pressing the joint. Sheets are denser to the facade. In this case, it is necessary to additionally press the edges and fix. Sometimes you can notice how the fungus nailed in the center slightly raises the edges of the foam, if the glue mixture has not yet “taken”.

- The fungus sometimes does not reach the required level and sticks out, respectively, the drill malfunctioned or sharpened, you need to redo the hole. Although this is painstaking work, you will have to pull out and drill the fungus, then reinsert it.

Finishing Edges

Upon completion, the walls are revised to eliminate large differences at the joints. Wide gaps will have to be foamed by inserting the nozzle of the gun.

- Thin strips of insulation are placed with foam on sections wider than 2 cm. When the foam dries, the residues are cut off and the remaining protruding defects are corrected. It is better to use a foam grater or clerical knife.

- Upon completion of the joints, the joints of the insulation and fungi are reinforced, primed and putty with a wide spatula. After final processing, all “constrictions” should be aligned, making up a continuous surface.

- Protruding fragments are cleaned with a spatula or knife after drying. Grouting is completed with a special emery grater.

Insulating the walls with polystyrene foam on the outside with your own hands is not very difficult, but requires attention. The instruction will help you do everything correctly and in a short time.