Styrofoam plaster - how and why it is needed

Are you tired of “warming the street” and overpaying for heating every winter?

Then it's time to start warming the house. The most affordable way is to clad it with polystyrene or foam, and then plaster it to protect the insulation and externally ennoble the house. About how it is performed foam plaster do it yourself, read this article.

The content of the article

Why and why plaster foam

To begin with, why many people choose foam plastic as a heater. The reason is simple: low price, low weight, not creating a load on the foundation, and ease of installation.

But this material is not at all durable, is destroyed by exposure to ultraviolet rays, atmospheric moisture and temperature changes. And it doesn’t look very good. Therefore, we need its exterior finish, as often used plaster.

Note. A relative of the polystyrene foam foam has the best technical and operational characteristics. In addition, mice and other rodents do not favor him. But it costs more, and still requires decoration.

Now about what should be the plaster for foam:

- So how is it about exterior decoration, then it must be durable, water and frost resistant. Therefore, gypsum-based compounds can be forgotten, only cement mixtures are suitable.

- And not those that are made directly on the spot from cement, sand and water, but special ready-made dry mixes designed specifically for such work. In addition to the main components, they include additives that improve the adhesion of the solution to the base and increase the quality of the finished surface.

- If you have already watched the video on how to plaster polystyrene, you probably noticed that the reinforcing mesh is first glued to it, and only then the surface is leveled. For these works, various mixtures are produced - glue and leveling.

- But in the assortment of some manufacturers there are universal compounds that can be used at any stage.

What to choose is up to you, but remember that it is better to use products from the same manufacturer, as different brands may differ not only in color and structure, but also in composition, and may not interact well with each other.

For reference. To determine the amount of material, use the following values: 10 kg of universal mixture or 4 kg of adhesive and 6 kg of plaster for each square meter of wall.

Rules for plaster polystyrene surfaces

You will not be able to complete all the work in one day. And not because of a lack of experience, but simply because you will have to strictly adhere to the technology.

The instruction requires arranging intervals between the main stages of work, which, depending on the temperature and humidity of the surrounding air, can range from several hours to several days.

If you want to know how to plaster on the foam correctly, read the detailed description of these steps.

Solution preparation

This stage cannot be called the first, but rather - periodically repeated.The fact is that plaster on polystyrene foam, as, indeed, any other mixture based on cement, quickly loses moisture and thickens. It is impossible to dilute it, since lumps will inevitably remain, and it is difficult to work with a thick solution, moreover, it will lose its adhesive properties.

Therefore, it is prepared in small portions immediately before use. The preparation itself consists in mixing the dry mixture with water and thoroughly mixing it with a drill with a mixer nozzle. Proportions are indicated by the manufacturer on the packaging, carefully read these recommendations before proceeding with kneading.

Tip. Before each kneading, thoroughly clean the container and mixer from the hardened solution. It is better to keep the nozzle in operation in a bucket of water.

Reinforcing mesh installation

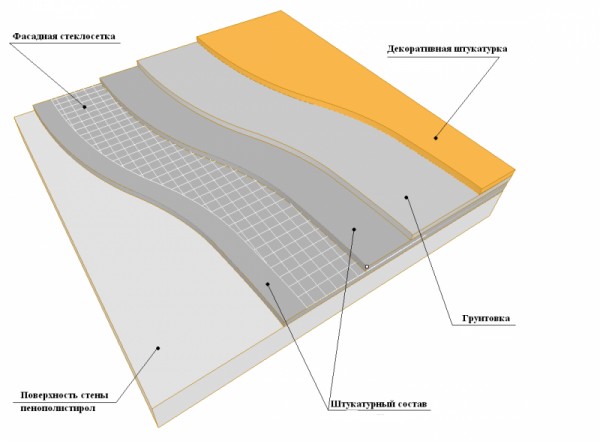

Polyfoam and penoplex have a surface that is not capable of high-quality adhesion. In other words, the solution does not adhere well to them: it either falls off over time, or becomes covered with cracks.

Therefore, before plastering the foam, the surface must be reinforced with a special mesh, which will improve adhesion and give the finishing layer greater strength.

When choosing a plaster grid, give preference to a material with the following characteristics:

- Alkali resistance. Cement mortar is a rather aggressive substance with an alkaline reaction, capable of destroying materials unstable to it;

- Density is about 140-160 g / m2. A less dense mesh will not provide high quality adhesion of the plaster to the polystyrene foam base, and a denser mesh is difficult to work with, especially when reinforcing corners.

It is with this that the do-it-yourself plastering of the foam begins - with the fastening of the strips of the mesh to the outer corners of the house, window slopes and other protruding structural elements.

This is done in this order:

- The grid is cut into strips of a width of about 30 cm and a length equal to the length of the corner.

Tip. Since it is inconvenient to work with very large segments, it is advisable to make strips no longer than two meters and glue them with an overlap.

- The strip is folded in half lengthwise and tightly compressed along the bend to create a stiffener.

- Having prepared the required number of strips, knead the solution and immediately proceed with installation.

- With a spatula, apply the mixture on both sides of the corner to a width of 20 cm with a layer of about 3 mm, attach the prepared strip to it and press it into the solution, acting with a spatula in the direction from the corner down and to the side on both sides.

Thus, all corners are pasted, after which the grid is mounted on a plane.

Due to the quick drying of the solution, work is carried out in small areas:

- A piece of approximately the same length is cut from a roll 1 meter wide;

- An adhesive or universal mixture covers a section of the wall with a size of 0.9 by 0.9 meters (10 cm on both sides are left to glue the joints during the installation of the next strip);

- As in the case of corners, the grid is superimposed on a fresh solution and pressed into it with the smoothing movements of a wide spatula from the center to the edges;

- Under the pressure of the spatula, the mesh is immersed in the solution. If it is not enough, a small portion of the mixture is additionally collected on the spatula and applied over the canvas;

- Each following strip is overlapped, joints are processed especially carefully;

- The last strip adjacent to the opposite corner, if necessary, is cut in width.

After fixing the mesh over the entire surface, allow the solution to dry. In dry and warm weather, this will take 4-8 hours, in wet and cool - 1-2 days.

You can evaluate the degree of drying visually and by touch - the surface should be the same color, without dark spots and not leave a feeling of moisture in the palm of your hand.

After that, it is necessary to wipe it, securing sandpaper on the construction grater. Work is performed in circular motions with little effort. Your task is to remove the influx, sag, frozen plaster spray.

It is important. If the surface is left to dry for several days, the solution will gain such strength that it will take a lot of effort to grout. Therefore, plan your time in such a way as to complete this stage in a timely manner.

Leveling

If you succeeded in gluing the grid in a quality manner, then this step will not cause you any difficulties.

Before you begin, look at how to plaster polystyrene video and read our recommendations:

- Prepare a solution from a leveling or universal mixture in such an amount that you can use it in 30 minutes;

- Take two spatulas: narrow for scooping up the solution and transferring it to the working tool, and wide for applying and smoothing;

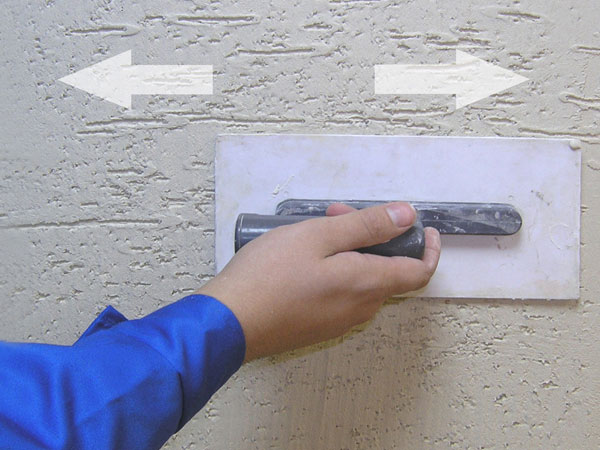

- Having placed a small amount of the mixture on the working spatula, attach it to the wall at a slight angle and smoothly and confidently pull it to the side and down or up so that the solution is distributed on the surface with a layer of 3-4 mm;

- Collect the remaining mortar on the working spatula with a narrow auxiliary one, transfer it to the blade again and distribute it along the wall with a movement across the applied layer;

- Start work from the top corner, gradually moving to the side and down until the entire surface is covered with a thin layer of plaster.

If before plastering the polystyrene foam, you have sanded the previous layer qualitatively, then it will be easy to work. Try to apply the solution so that the joints between the two portions do not coincide with the joints of the reinforcing mesh. This will make the seams invisible and avoid the appearance of cracks.

Then again trowels follow, which are carried out at the same time interval and according to the same principle as after the installation of the grid. Unless they require more attention and thoroughness to achieve a flat and smooth surface.

Decorative plaster

One of the most common methods for exterior decoration of private houses is decorative plaster. In our case, after warming with foam in this way, you can decorate any building, even wooden.

But before you start applying the bark beetle plaster on the foam, protected by ordinary plaster with a reinforcing mesh, the surface must be primed (see Primer walls and all for that matter) This work is inexpensive both in costs and in time, but is invaluable in its benefits.

So:

- Firstly, the primer increases the adhesion of materials, and the decorative finish will hold on the walls better;

- Secondly, by reducing the absorbency of the substrate, you will be able to save on expensive finishing material;

- Thirdly, when using a primer with antiseptic properties, you will avoid the appearance of mold on the walls.

Therefore, do not neglect this step. Apply the primer to the walls with a roller or brush, creating a continuous layer and avoiding drips, and let it soak and dry.

Decorative plaster is applied in the usual way, but until the layer on the treated area is dry, it is given the desired texture. This is done using a grater, a decorative roller or other devices. You can learn more about this from our other materials on this topic.

Surface painting is started after the textured decorative layer dries.

Conclusion

We tried to tell as much as possible about the plastering of walls on polystyrene foam. If something remains incomprehensible, the video in this article will help you figure it out.

Now, even if you do not dare to independently insulate the house and finish it in this way, you will know how such work should be done and you can control its implementation by contractors.