Finishing window slopes in different ways

Finishing window slopes is an important element of the interior and appearance of the room. First of all, the window material determines this, but there are other options.

After installing the window, everyone has to do it. Therefore, this article will help to understand this issue and make the right choice.

You will have the opportunity to see photos on this topic and see the appearance of the product and the possibility of design.

The content of the article

Solution preparation

In almost any finish, you will need a quality solution. The fact is that making a slope is much more difficult than just plastering.

The mass of the mixture should be completely homogeneous and not have lumps. It is necessary to monitor the density.

Having become too liquid, you will observe the influx. So more when to do the processing of the upper slope.

Too thick will not be elastic enough.

So:

- First of all, it is better to pass the dry mixture through a sieve. With this we completely get rid of rubbish and pebbles;

- After that, we fill it in a container. For this, a plastic paint bucket is best suited.

It has a flat bottom and will not interfere with cooking; - Pour the powder there and start adding water while stirring the solution with the second hand;

- After that, we need to achieve mass uniformity. To do this, it is best to use a drill with a nozzle. It is with the help of this, not tricky device, that you can make a quality solution.

Slope trim options

In principle, there are three main options that apply to this work. It all depends on the window itself and the place to be filled, that is, the height of the layer.

Too much mortar should not be applied, such a design will crack.

Stucco finish

This is perhaps the most common option. It can be seen in many versions.

Some use stucco for decoration.

But the question here is that everything must be done according to certain rules and to comply with manufacturing technology. Then the product will serve you long enough.

So:

- After installing the package, an unfinished plane remains, which should be properly prepared. Otherwise, the material will not have a high-quality bond with the surface and after a fairly short period of time will begin to flake;

- We do an inspection of the plane and determine how much and what we need. The fact is that if the gaps are very large, then here you can’t get off with a simple solution.

There will be temperature differences and high humidity. Therefore, there may be cracking of the material.

If the cracks are not large, then ordinary cavity plastering is required. With a gap of up to one cm, the second option is also suitable, with a gap over this size, stones should be introduced into the plaster; - To begin with, we clear the surface of mortar and gravel. If the material began to exfoliate as a result of the installation, then it should be removed with a hammer and a chisel.

If the gap is less than 5 mm, then it is worth expanding, this will improve adhesion and allow the solution to hold better;

Attention: Finishing slopes is carried out only after the completion of work on the wall plane. Do not begin this work until the walls are completed.

Otherwise, everything will have to be redone in a new way. Some in the gap cause foam, but this should not be done.

It is quickly destroyed. Everything should be done, as for yourself.

- First of all, we need to fill the seam between the frame and the wall. To do this, it is best to use felt or tow.

Before work, these materials should first be moistened in a gypsum mortar and after that the plane is compacted around the entire perimeter of the window. This will serve as a heater; - Do not completely fill the insulation to the edge of the frame. It is necessary to leave a gap to the end of at least 20 mm.

We will need this for high-quality application of the solution. We bring the material into the opening and wait for it to dry completely; - We make a solution and put it in the opening. It is worth doing immediately a large layer.

Apply strips around the entire perimeter of the opening with a thickness of not more than one cm. After that, apply the next layer. The window can be aligned with a spatula;

- Now we need to make the slope plane. At us it turns out not equal, but at an angle.

To do this, we need a spatula with a width greater than the slope of the window. If a person cannot withstand the angle of inclination, then a rail will also be needed along the height of the inclination from the window; - We take the solution on a spatula. We apply the bar from the window and begin to apply the solution.

If the height is too high, then immediately the bar can not be applied, but begin to apply small layers and gradually, after drying, the subsequent ones. So a little closer to the finish line;

Attention: We put the spatula at an angle. We get the application of the solution from one edge.

Do not immediately apply a large coat. The material just floats downhill. We must work slowly.

- After we have to put the last five mm. we put the finish. And we are waiting for complete solidification.

After that, we put the building grid on the grater and begin to display the plane. It should be perfectly flat;

- The perfect surface will not work right away. Shells will remain.

Again they need to be applied with a narrow spatula. Wait for curing and then wipe again.

We do this until we get exactly what we need.

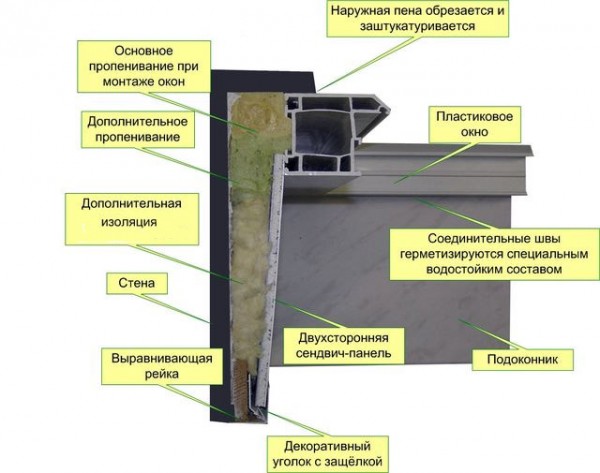

We make slopes from plastic

If you put plastic windows and you need to put a large layer of plaster on the slope, then this can be avoided by installing plastic slopes (seeFinishing slopes of plastic windows - all the subtleties and rules) This is not a difficult job that you can do with your own hands.

There is another plus. After all, the window and the slope will be made of the same material and when the temperature rises, the expansion will be exactly the same and therefore no additional expansion will occur in the slope.

Not a high price also speaks for acceptable use. This process can also be seen in the video.

So:

- We completely clean the surface from the previous coating, as described earlier. We treat with antiseptics;

- We take measurements and cut strips of PVC;

- We fix the special rail to the plane. It has a special clamp, or latch.

You can make such a base for mounting and not of plastic. Just then you need to attach wooden planks to concrete.

This should be done by making holes using a perforator and fastening using dowels; - After that, the panel is attached to plastic using liquid nails, and fastening to a wooden surface should be done using a stapler;

- A small gap may remain at the edge, which is hidden by the plastic corner used to make the edging.

We make a slope of drywall

Sometimes it happens that with window trim it is necessary to apply a large layer of plaster, then it is better to make such a slope with the use of drywall. In subsequent processing, it will look like ordinary plaster.

So:

- We completely clean the surface from the previous coating and do the processing as described in the first embodiment;

- We will need to do the installation of drywall to the plane. For this, an I-shaped profile is used, which makes the edging of the entire plane.

This element has a groove into which the material is inserted. Height adjustment is done using gaskets. - This can be done with the help of wooden bars. To do this, before installing the rails, we process using antiseptics and allow the material to dry completely.

After that, cut the wood to the desired size and fix it to the surface using a punch and dowels. Adjust the height of the pads; - Cut out the material of the desired size from the sheets. After that we fasten it to the prepared surface.

This is done using self-tapping screws. In this case, the hat should be drowned from the plane by a couple of mm .; - When attaching to plastic, apply acrylic sealant to the groove and insert a strip into it. In this case, a heater should be placed in the cavity under the bottom;

- On the side that is removed from the window, apply glue and press. This is best done with a level or wooden plank.

Press should be done all over the plane at once; - We are waiting for complete drying;

- Now we need to make a solution and finish the wey plane, as described above.

On the edge of the slope it is better to let a metal sickle. She will strengthen the corner.

If you made the installation of expensive wooden windows, then the finish looks a little different:

- To begin, we beat the bar of the desired height around the entire perimeter of the window;

Attention: When choosing the height of the film, one should not forget about the height of the drywall and the coating that will be applied to it. Make high-quality measurements and provide for this.

- Cut drywall to the desired size. We fix the side of the window on the foam.

We fix the opposite with glue; - We paste tape around the entire perimeter at a distance of 3 mm from the edge of the window;

- We take the gun and apply the acrylic sealant in this place and simply push it into the gap.

We fill it completely. After that, remove the entire sealant with a wet finger; - After that, remove the whole tape.

This is how to finish window slopes in different ways. There is an instruction, now you can get to work.

The most important thing in this matter is not to rush and not to dirty the window surface.