Plaster beacons: how to choose

The stucco beacon is quite famous among professionals. But not all consumers have an idea about it, but if you decide to do the repair yourself, then you just need to know. After all, the use of this part greatly facilitates the work and helps to make a perfectly flat plane.

Today we will tell you how to put beacons for plaster and choose them correctly. Also, a video in this article and a photo will be presented to your attention, where you will see a lot of useful information.

The content of the article

Beacon Features

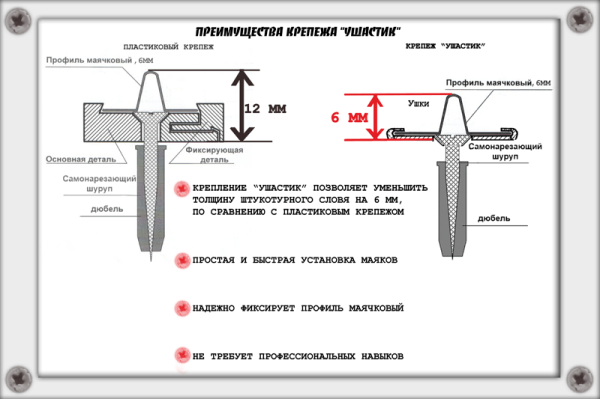

The plaster beacon is classified first of all by what materials they are made of. There are plastic beacons and stainless steel. There is also a difference in their configuration, let's understand these issues in more detail.

| The size | They should be distinguished by their size, minimum - 3 mm, maximum - 30 mm.

|

| Profile configuration | There are many configurations, but in stores only the most popular ones are mainly represented. The beacon profile for plaster should be selected depending on the material of fastening. |

| Design Features | The beacon profile for plaster can have a rather different appearance:

|

How to install beacons under the plaster

Many people who encounter beacons for the first time do not understand what to do with them.

Everything is pretty simple:

- First, carefully inspect the wall, you can even touch it slightly, it is important to understand what it is from. The method by which you will attach the beacons depends on this. Lighthouses are mounted on concrete and a brick wall using plaster, and on a wooden wall using self-tapping screws or nails. When inspecting the wall, be especially careful about the seams so that there is no excess solution or, on the contrary, too little.

- A visual assessment makes it clear how much lighthouses are needed based on the experience of the worker and the width of the rule. After visual inspection, it is the turn of the level (water or laser). Use it to make sure that the walls are vertically even. In this case, the level of deviation from the norm will mean the thickness of the plaster layer.

- Cement-sand mixture applied in one layer, the thickness of which can be from 2-3 mm to several hundred mm. In such works, the beacon is usually set at the smallest distance from the wall. One of the prerequisites for the installation of beacons is the installation of the first beacon in the corner of the doorway. If you ignore this, then there is a threat that you will not be able to continue to observe the correct degree.Next, you can begin to attach the beacons depending on the type of wall.

Varieties of plaster

Not every plaster needs machets. For example, this applies to decorative types of plasters. In this article we will not talk about them in detail.

Another option is wall plastering, when the walls are plastered at once in several layers. Beacons, in this case, are installed in turn at each level. They are plastered separately from each other. To clearly outline these levels, angular beacons are actively used.

| Cement-sand (rough) plaster | Today, for many types of surfaces, cement-sand mixtures are often used. Such plaster often serves as the basis for the next layers and is often called rough plaster.

|

| Gypsum plaster | Very often, a universal gypsum type of plaster is applied on top of a cement-sand layer (rough coat). But there are also cases where gypsum plaster used as the main and only coating for the wall. In such cases, the use of beacons is limited, due to the fact that by applying a thin layer of gypsum plaster it is not always possible to completely cover the guide. |

Tool selection

You should be prepared to work with all responsibility and start by choosing the necessary tool:

- First of all, you will need 2 tools - the rules. Qualitative long and short rules will help you do the job well. When choosing these tools, one should proceed from the fact that the long rule should be slightly shorter than the height of the wall to be plastered, and a short rule is necessary to level the solution layer.

- In the course of work, you will also definitely need: a puncher, a trowel, a half-trowel, a spatula (preferably large), a level (liquid or with a laser), a hammer and a chisel.

- As mentioned above, in preparation for work, a control inspection of the walls is carried out, during which it is expected that the level will be actively used to identify and eliminate rough ledges in the masonry.

- Separate sections of the wall are leveled with a construction hammer, if there is an old coating that has begun to peel off or if there are sagging mortar. All this must be removed in order to achieve the greatest evenness of the overall plane of the wall.

Attention! Only when this is achieved does the surface begin to be primed.

Installation of beacons is carried out only after priming!

It is equally important to achieve the highest possible level of priming of the walls before plastering! The exfoliated layer of plaster cannot be glued, which means that repairs will cost you not so cheap as forethought.

Beacon Setting

Step-by-step beacon setting:

- Installation and alignment of beacons (see Installation of beacons for plaster without problems)

- Putting plaster mix on a wall

- Retrieving Profiles

- Sealing the remaining seams

The installation itself is done in the following order:

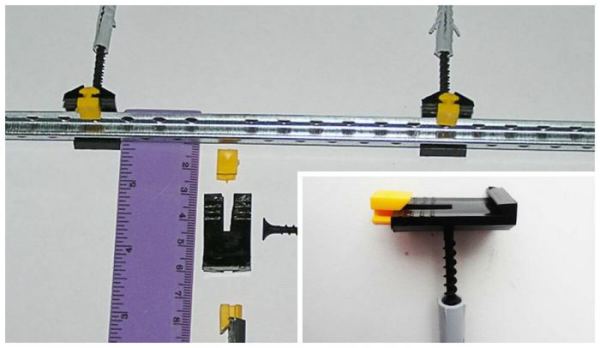

- On a primed wall mark places under beacons. Where necessary, holes for fasteners are drilled. You can use a drill in which there is a shock mode, but better - a hammer drill.

- The choice of step corresponds to the length of the rule. It is most convenient to use a dowel-nails. You can choose the size by eye, but 6 to 80 is usually used.

- Having installed the fasteners with the help of self-tapping screws, they are aligned with a screwdriver, the heads should be in the same plane - this is very important. For greater certainty, they often resort to tricks and pull a thread, cord or line along the diagonals between the self-tapping screws. Accuracy is determined by the place where the threads intersect.

Attention: All these operations should also be taken with all responsibility, to be carried out as scrupulously as possible, since the thickness of the plaster on a perfectly flat surface, in the end, depends on this. The best thing is to achieve the smallest possible thickness.

After the landmarks are set, you can proceed to the next operation - the direct setting of beacons. Along the line, between the screws, a little mixture is applied to the wall.

- Next, beacons are installed. They are aligned with a simple rule using a simple click. It is necessary to press through the rule until it stops (in the head of the self-tapping screws). The resulting solution is also leveled or trimmed.

- Check for flatness. If at the same time you find deviations, they can be eliminated by screwing or unscrewing individual screws with a screwdriver.

- The solution sets, after which an operation is performed, during which the beacons are coated with a mixture on both sides for better fastening of the guides. So they are firmly fixed in one position and will serve as an emphasis when leveling the mixture.

Stucco walls on beacons

Lighthouse wall plastering is done quite often, this will be mandatory especially with a large coverage area. Lighthouse wall plaster video will show you everything clearly, and theoretically, the separation is as follows.

Option number 1

This option provides for plastering on beacon profiles and the simplest, preferred and most popular method today.

- The profile is installed parallel to the beacons and fixed with a solution. This process can be accelerated using a quick-drying gypsum mixture. After a couple of hours, you can begin to level the main layer.

- Methods of fastening beacons with plaster pretty simple. A solution is placed vertically, closer to the lighthouses, in the form of a strip. This is not necessarily a continuous streak. You can restrict yourself to intermittent, consisting of individual mounds located in a line. Next, the profile itself is pressed into the strip of the solution. It is very important to ensure that the top of the profile coincides with the beacon.

- Using the flat part of the half-trick, press the profile so that it touches the beacons. After that, for better fastening of the strip of the beacon profile, it is also preferable to coat with a solution. Make sure that the solution on the profile is set, only then continue to work.

- Spraying, followed by leveling the plaster mixture, it is recommended to carry out a certain method. Spray should be in small areas of no more than 2 m². Each such section after this should be leveled as carefully as possible, leading a half-up to the bottom. Then the remaining irregularities are erased.

- The first pass as a rule after applying a layer of the solution will require some effort and attention from you. The rule should be carried out directly along the upper edge of the profile, while shifting from side to side. Do not forget to cut off excess solution.

- If after passing the rule there are dimples on the wall, throw a little mixture in them and draw the rule over them again. Similarly, self-plastering is carried out. Often after this, the profile remains in the wall.

- It happens that at the end of the plastering process, before setting, the profile is immediately removed, after which the grooves remaining in its place are overwritten with a solution. The profile is removed because there is a risk that it will rust and then rust will sooner or later come through the wallpaper.

Option number 2 (retro)

A beacon profile is not needed.This option is not very good for beginners, since it is assumed that the guides are made from the solution itself, it is quite difficult to fashion them without experience. As for the exhibition of beacons, this happens the same way as in the first method.

- Between the beacons they pull and fasten the cord (vertically). The cord should be strong enough to throw a vertical strip of solution over it with a strip. In this case, sometimes you should press them with a trowel.

- The process should be constantly monitored, avoiding the sagging of the cord as a result of the next slap of the solution on the surface, otherwise dimples may occur. As a result, we get guides that replace the profile comb.

- You can start plastering as soon as the mortar on the guides grabs the solution, and the cord is removed.

How to put beacons under the stucco video will help you do everything right. There is a manual and it is quite possible to start work, the price will not be high if you do it yourself.