Plaster grid: how to use

Surely, many people came across stucco with a complex interweaving of cracks or even falling off pieces. The first thought is negligent workers. But this is not always the case, often the poor quality of the plastered surface is a consequence of the customer’s savings on materials and finishing components.

In this article, we will talk about what is a plaster cpvs grid, as well as about other materials that improve the quality of the plaster.

The content of the article

What is the mesh for?

If you ask a person who is far from construction, how concrete differs from reinforced concrete, many people will probably answer that reinforced concrete mixes with iron, which makes it much stronger. In part, this is so, only the metal that is added to the concrete is steel reinforcement, interconnected.

It is she who gives strength, and the resulting material is very difficult to destroy. It is about the same with plaster, only instead of a thick wire of reinforcement, an assembly grid for plaster is used here. She strengthens the mixture and prevents her from cracking and falling apart.

However, going into any hardware store and looking at the plaster nets, it turns out that this is a very generalized concept and there are a lot of nets themselves. So what is the difference between stucco grids and how to choose them correctly?

Well, first of all, this is of course the material from which they are made, and there are several options:

- Metal.

- Plastic.

- Composite fiberglass (see Fiberglass plaster mesh - types and scope).

In turn, the metal mesh can also be different:

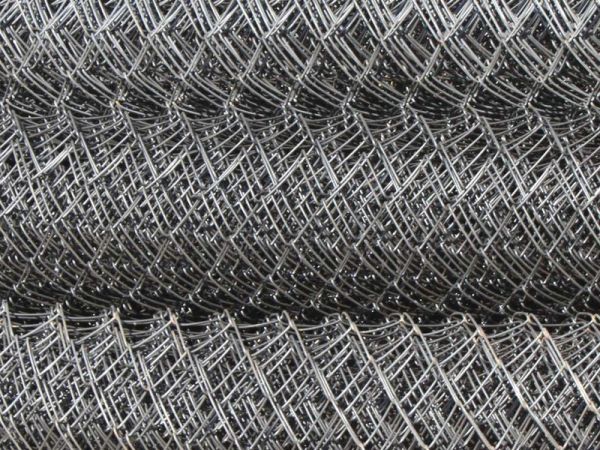

- Chain-link - mesh, which is a weave of thin wires. It can often be found on fences and other fences.

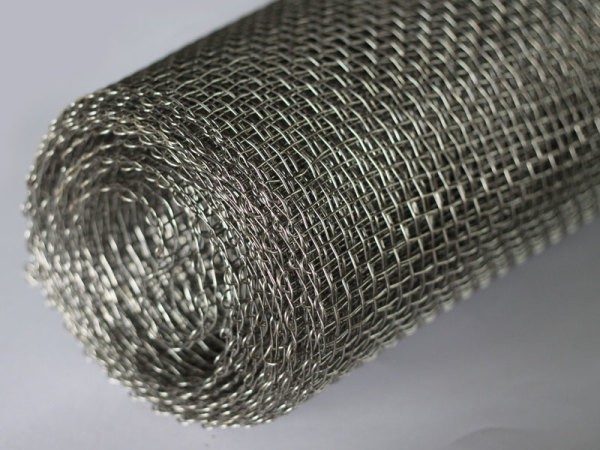

- Welded plaster grid - It reminds a chain-link, but here the wires are not intertwined with each other, but are welded to form square cells.

- All-metal cut-through exhaust mesh or, more simply - plaster mesh cpvs. It is a metal sheet in which cuts are made and extended, resulting in a dense mesh resembling a honeycomb.

In addition, each type of metal mesh can be:

- Purely metallic.

- With galvanized coating.

Interesting! The galvanized mesh of the cpvs plaster, the most expensive, but also the most durable. For wall plastering, this material is rarely used and not only for the sake of economy, just the technical parameters of the central air conditioning system are never useful on simple walls.

And if we are already talking about metal grids, then we will dwell on them in more detail.

Details of metal grids

Chain-link

Over the years, when more and more competitors appear in the chain-link, it is rapidly losing its popularity. And the matter is not the quality of this material, since the chain-link is also galvanized, and therefore stainless, the point is the difficulty of working with it, especially since the price of the chain-link is not significantly different from the welded wire mesh.

In order to properly tighten the netting on the wall, it needs to be fastened very often, and this is an additional material expense, and besides, it takes a lot of time.

And even the plastering of metal beams along the netting is irrelevant, since it is almost impossible to weld a thin wire by welding. To clearly understand how the process occurs, you can watch the video plaster on the mesh-netting.

Welded wire mesh

Unlike the netting, this mesh is much easier to attach to the wall, as it has a dense structure and fits perfectly on the surface. Today, the welded mesh can rightfully be considered the most popular among builders.

It has an attractive price and is easy to work with:

- In addition to plastering, welded wire mesh is often used as a reinforcing material for pouring concrete, or concrete screed. It strengthens the screed and prevents it from crumbling under pressure on itself or sudden changes in temperature.

- In addition, plaster and reinforced concrete are able to tolerate more freeze-thaw cycles. Well, a small overview of what a welded mesh is, you can see the video in this article.

Important! It is undesirable to use any kind of metal mesh for interior work, and especially for gypsum plaster. Sooner or later, the metal will begin to rust and yellow spots may appear on the plaster, which will be difficult to remove subsequently.

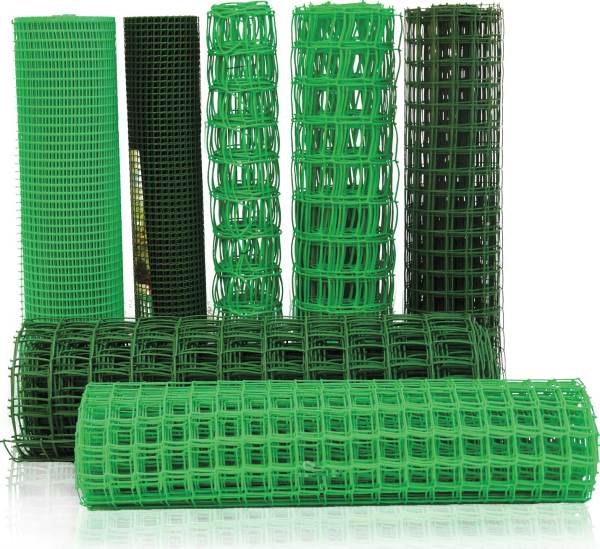

Plastic mesh

The cheapest material that fits perfectly with gypsum or acrylic plaster. Today, plastic is used everywhere and reinforcing mesh is no exception.

Plastic mesh may vary in density, size, and cell configuration. In fact, there is no fundamental difference in the configuration of the mesh, it will not affect the quality of the surface, the issue of convenience is more relevant here, especially if it is decided to do the plastering yourself.

Another important nuance that you need to know about - plaster with a mesh of plastic is not done on mineral, that is, cement mixtures. The fact is that plastic is affected by alkali, which is present in large quantities in cement. If the plastic is not adapted to the alkaline environment, then in less than a month there will be no trace of it, and cracking will begin in the resulting voids. Today, some manufacturers have resolved this issue and are adding special additives to the plastic, which make it immune to alkaline environments, but even this is not a guarantee of long service life. And here you can only trust what the manufacturer wrote on the packaging, and we all remember the saying about how the inscription can differ from reality.

As for mixtures on a gypsum or acrylic basis, the plastic mesh is not inferior to competitors in any way, and given the relatively low cost, it even wins.

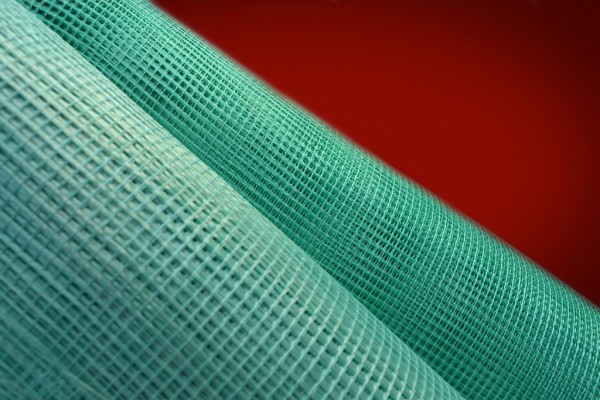

Composite

Dealing with the question of which mesh is better for stucco, there is only one answer - composite fiberglass. This is the most stable material of all presented to date.

Glass fiber is not afraid of any adversity, but in order not to engage in long discussions, we simply list the main advantages of this material:

- Glass fiber is completely neutral to alkali, therefore it can be used in cement mixtures and does not dissolve in them.

- Full resistance to moisture, which qualitatively distinguishes a composite mesh from a metal one.

- Immunity to all types of solvents that can be used in construction or repair.

- The composite does not expand with increasing temperature, as can happen with plastic and even metal.

- It does not burn itself and does not support combustion.

- Totally environmentally friendly.

In a word - this is the most durable material, which today has no competitors in quality.