Plaster corner with mesh: what is it for

Plaster corner with mesh is used in construction quite often. It greatly facilitates the decoration of corners and allows you to make a quality plane.

Today we will tell how the plaster corner with a grid is applied and where. You can also watch a video in this article and a photo where everything will be shown visually.

The content of the article

The technique of plastering

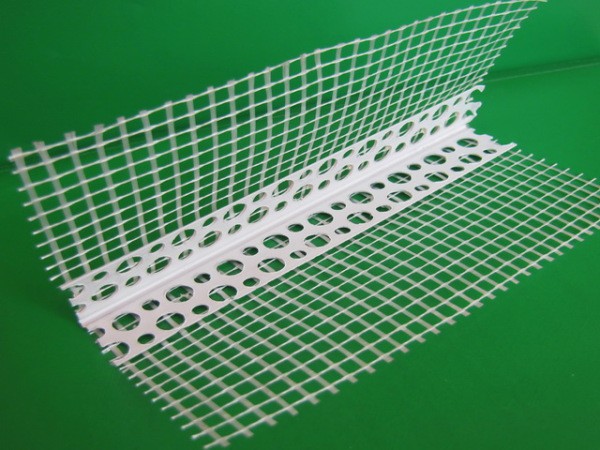

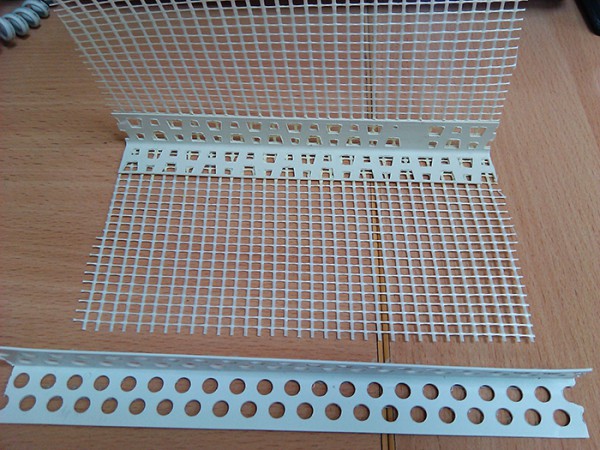

Plaster mesh corner is made in two versions, this is for the outer and inner corners. The material of manufacture can also be plastic or metal. The choice will depend on the shape and material of the trimmed plane.

All work can be completely done with your own hands, then its price will not be significant. Let’s now consider the different options for doing the job.

Interior Corner Finishing

When carrying out work on plastering walls, the interior corners are finished in two ways:

- Joining of the processed and revetted walls,

- Plastering two walls at the same time.

Attention: The mesh plaster corner will make use in both versions. It will allow you to withstand the direction of the angle in a geometrically correct form and significantly strengthen it.

- Spraying spray and primer (seeWhy do we need a primer: technological nuances of finishing work) is carried out according to the classical method, leveling is done using the rule, starting from the corner and further along the wall. Then they begin to form an angle, for which markings in the form of scratches are made on the surface of the solution.

- Grater or trowel should be applied with the edge to the previously plastered wall. The angle should be approximately 30 - 40 degrees. Then you need to bring it to the inner corner, lay it on the recently faced wall surface and wipe it. Movement should be up and down. After this, the tool should be laid with the base on the newly plastered surface, pressed flat against the faced wall.

- Making movements with significant pressure, they are cleansed of the plaster mixture. It is necessary to wait for the primer to solidify, and then apply the final layer - a coating on its surface.

- Smoothing the finishing layer of the cover is carried out using a grater of wood or foam. At the same time, care must be taken so that bubbles, indentations and protrusions do not form. It is important to achieve even coverage of the entire wall.

At the final stage of processing the corner, the grater must be kept so that the lower edge lies on the facing side, and with the angle it touches the plastered surface slightly. - The tool must be driven up and down along the entire length of the corner. The result of the measures will be a strictly calibrated rib between two compatible walls.

- By the same technique, two joined walls are processed.

Attention: To smooth the solution, you should purchase an angled spatula. This will maintain the correct geometry of the angle.

Exterior corners

Outside corners are produced by two methods. They are suitable for repair work and for construction.

So:

- The first processing method uses an angle profilemade of metal. This allows plastering simultaneously of both combined walls, while achieving high angle strength.

- In the second processing method, the work is divided into two stages. Both sides of the corner are plastered in turn.

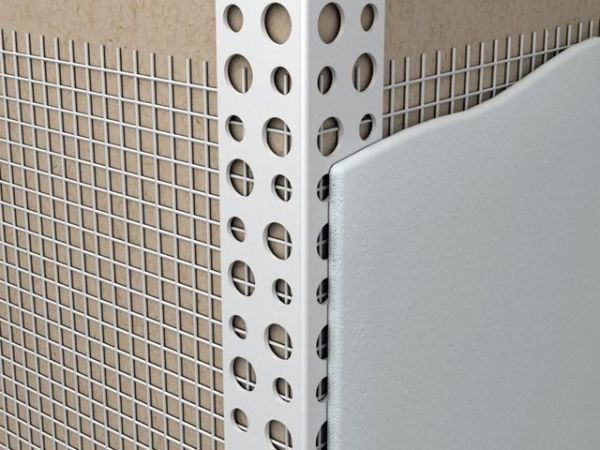

Attention: Angle-protective plaster mesh profile allows you to easily obtain the outer corner of the wall, characterized by high strength and smooth surface.

- Both sides of the metal profile are attached to its central part and are nets. Their thickness depends on the rail model. Fix the profile with a normal solution and allow it to solidify. After this, a primer is applied.

- Corner rail can be installed on a small layer of plaster. To do this, apply the solution, starting from the floor to the ceiling. This will simplify the work on leveling the profile. Any metal corner profile is easily shortened if required.

- Shelves - nets can be easily cut with scissors for cutting metal, and cut the central part with a saw. The installed rail can be used as a beacon when smoothing the primer.

The solidified solution is cut using a steel trowel.

Attention: This allows you to free up space for the coating layer, which is applied by the classical method. Its thickness depends solely on the angular profile. To give the corner a rounded shape, it is treated with a fine skin.

Slope Finishing

Slopes are the surfaces of door and window openings located at an angle of 90 degrees to the wall. When performing work on plastering slopes, it should be remembered that it is necessary to maintain the same parameters for the depth and thickness of the applied plaster layer.

Attention: This will allow you to achieve a uniform width of the entire part of the door or window openings, which will remain visible. The same slope depth can be achieved using an angled profile made of metal. It is equidistant from both the lower and upper surfaces of the door frame or window frame.

To achieve a uniform thickness of the plaster layer, it is better to use a special template when decorating slopes.

The technique for finishing slopes yourself:

- At the initial stage, work is carried out to clean and primer the entire working surface.

- After the primer layer has dried, you should proceed to applying the plaster on the slopes. To do this, use a spatula.

- To get smooth angles, you should use metal corners. They are mounted on the surface with plaster and coated. You can also use a template to achieve a flat surface.

- As soon as the plaster layer hardens, the entire surface of the slopes is cleaned with sandpaper.

Mistakes characteristic of plastering

There are some errors that are most common, let's look at them in order:

- To begin work on plastering without evaluating the technical condition of the foundation. Because of this, in the near future you can encounter such nuisance as cracks and peeling of the plaster layer. This means that there will be a need to repair the cladding.

- Apply the coat, ignoring the primer. This will lead to the fact that when drying out, the outlines of the building materials from which the building is built can appear on the walls.

- Apply a gypsum base coat directly to the base of porous concrete blocks. These building materials do not interact very well with each other, which can provoke numerous cracks in the plaster layer. It is better to use such a coating layer, where the polymer acts as a binder. You can use ready-made gypsum plaster, in which all the necessary substances are present.

- Long time intervals between plastering ceiling surfaces (seeHow is plastering the ceiling), walls, window slopes and doorways. The work should be carried out without major interruptions, so that each layer grasps equally evenly over the entire area.

- Level the walls with plaster on a concrete base with a moisture content not exceeding 4%. Plaster mortar will not adhere to the concrete surface.

- Non-compliance with the rules for plastering corners located on slopes. It is recommended to supplement the joints of the plaster coat with the box or frame with expansion joints. Before starting work, fasteners for expansion rails should be made to them.

- When the outer corner is located in places with intense passage, it is necessary to install a profile of steel or aluminum on it. If you ignore this recommendation, the angle in the production process can get significant damage.

- Cut galvanized profiles using a grinder. This method will lead to the destruction of the zinc coating, which serves as a protection rail against corrosion. In the future, rust spots will form on the cladding. Therefore, you can cut the profile exclusively with scissors and a hacksaw for metal.

Useful Tips

Cement and lime plaster today it is possible to buy ready-made, but you can make it on your own.

- To make the mixture Drinking water is more suitable than technical. It contains fewer different additives, which reduces the likelihood of efflorescence.

- To achieve greater smoothness of the facing layer, it is recommended to add finer sand to the solution.

- For plastering work at a temperature not exceeding 10 degrees, the mixture is made using Portland cement.

Important information

Finishing experts give some recommendations that are worth considering:

- Plastering walls of reinforced concrete and concrete should be done no earlier than 4 weeks after the completion of the grout.

- Plaster mix is recommended to be applied on the primed surface. In case of gypsum plaster This is a necessary requirement.

- After spraying, the primer can be applied with an approximately 8-hour break.

- It is important to remember that beacons must be cleaned after finishing work on leveling the plaster layer.

- If the surface is intended for covering with a facing tile, then you can do only with a primer layer.

- The formation of voids under the metal profile must not be allowed.

- Smooth the plaster layer in the inner corners with a corner spatula.

- Start painting the surface of the walls or wallpapering should not be earlier than 2 weeks after plastering with gypsum mortar. If the plastering measures were carried out with cement or lime mixture, the period is increased to 4 weeks.

The mesh plaster corner will make it possible to make a geometrically correct angle and will significantly strengthen it. And the instruction will not make mistakes.