How is plasterboard wall covering performed

If you have never heard of drywall, you are probably an alien from another planet, because this is the only way to explain the lack of understanding of this material. Radio, television and the Internet are full of materials about drywall, and even a child knows how to work with it. But not everyone knows about the secrets and subtleties of this process, and the pitfalls that may occur in the process.

In this article, we will talk about how do-it-yourself plasterboard wall covering occurs, and we will reveal some secrets that will help you create truly high-quality and durable repairs in your home.

The content of the article

The secret of popularity

Indeed, what is the secret to the popularity of this material? Maybe the technology of plasterboard wall covering is so simple that even a person without experience can do it?

Partly, but why then it is popular among seasoned specialists who are able to work with any material. Maybe the price is attractive? It is also possible, but this is not enough, and then, many people starting repairs in the house have an almost unlimited budget, which means that the cost is not an indicator for them.

Let's take a closer look at this material, and try to highlight its characteristic advantages, and most importantly, the differences from other sheet materials with which you could make repairs in your home:

- Price. This point can not be ignored, because for many it is he who becomes the determining factor in the choice of building and finishing materials. Drywall costs much cheaper than a sheet of plywood or chipboard, similar in size.

- Simplicity in work. Even a child will cope with drywall, and its installation will not require a cunning and dangerous tool. You can even cut a sheet of drywall with a conventional clerical knife.

- Fastening speed. Even if you fasten the sheets to the frame, then the installation of the drywall itself will take you much less time than the manufacture and construction of the crate. The technology of wall cladding with drywall does not imply drilling holes for screws, and this significantly saves time.

- A light weight. Drywall decoration practically does not create a load on the walls and foundation, which is especially true for buildings built of light materials, the load on the walls of which is undesirable.

- Versatility. Plasterboard wall covering is just one way of using this material. In addition to it, complete partitions are assembled from drywall, false ceilings are assembled (see.Facing the ceiling with drywall: do it right), as well as make decorative elements of the interior.

Important! Many people wonder if it is possible to use drywall for wall sheathing. It is possible, but you need to use for this special, fire-resistant sheets, which for convenience are painted in red or pink.Such drywall can easily withstand high temperatures, and does not deform.

As you can see, there are many characteristic advantages of this material, but the topic of our article is do-it-yourself plasterboard wall covering, which means it’s time to go directly to the installation process, which we will conditionally divide into several stages. It will be a question of mounting on a frame, since this method is more time-consuming, and as a result is fraught with more nuances and subtleties.

Preparation for installation

Wall cladding drywall always begins with the preparation of these same walls. The more carefully they are prepared, the easier the finishing process will go, and the longer it will last.

First of all, the walls must be cleaned of dirt, dust and old finishes. If you already had a hinged system, then there will be no problems, just remove the old frame. If on the walls were wallpaper or even more paint, then you have to pretty mess around.

Wallpaper, which is poorly torn off, should be abundantly moistened with soapy water and left for several hours. After that, they can easily move away from the base (seeHow to remove wallpaper from the walls correctly and without torment).

Such a trick will not work with paint, but fortunately today, in any hardware store you can find a special wash that dissolves the top layer of the coating, and it lags behind the wall without leaving a trace (see.How to remove paint from the walls: the secrets of the masters).

Important! Washings for paints are made from chemical solvents, so you need to work with them very carefully. Be sure to use personal protective equipment, and ventilate the room during and after work.

After all the elements of the old finish have been removed, the walls must be thoroughly swept out, and only after that apply a primer layer of deep penetration.

Many neglect this process, believing that if drywall is mounted on a frame, and it does not have direct contact with the wall, then antiseptics are not needed.

Really really needed. Mold, which develops due to the accumulation of condensate, will sooner or later come to the surface and leave unpleasant stains on the decorative part of the finish that cannot be removed.

After application, the primer must be allowed to dry, which can take anywhere from an hour to several days, depending on the temperature in the room and the level of humidity. After all the walls have thoroughly dried out, you can safely proceed to the next stage.

Build the frame

Well, here we come to the most important and crucial stage of our work - the installation of the frame. And before proceeding to the fastening of the guides, you must choose from what they will be made.

There are at least three options:

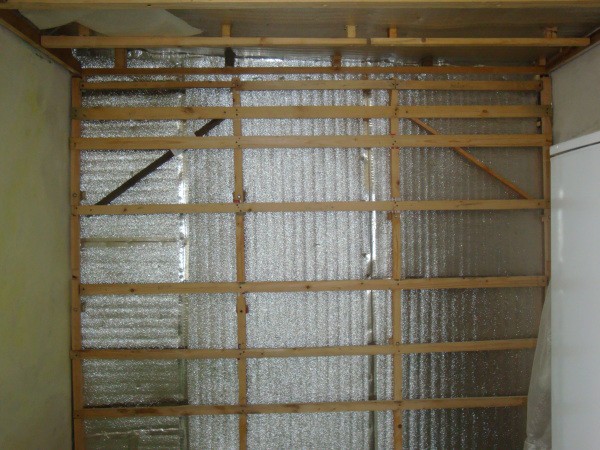

- Wood. The cheapest, but the least quality material for the manufacture of a frame for drywall. The main disadvantage of a tree is that over time it begins to accumulate moisture and deform, and this can lead to irreversible consequences. Of course, this can be avoided by using special impregnations for wood, but this will extend the service life for a short time.

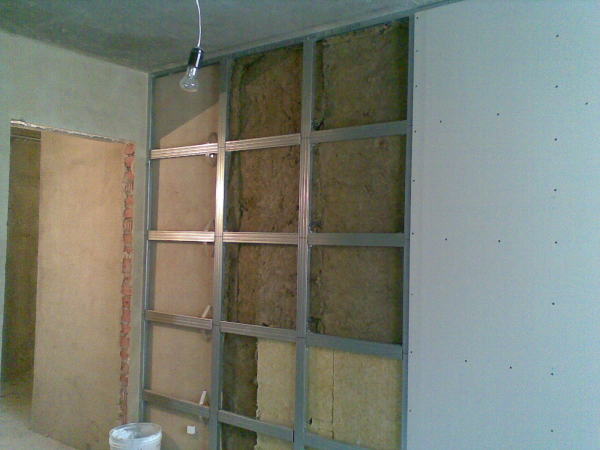

- Metal profile (seeLet's consider how to fix a profile for drywall to a wall). Material of the middle price category, which has only one, but a very significant drawback - susceptibility to corrosion. Over time, the metal will begin to rust, and yellow spots may appear on the finish, which will be difficult, or maybe impossible to remove. Paint can protect against this, but then the price of the profile itself will increase several times.

- Galvanized profile. The most expensive, but also the most reliable material for the manufacture of the frame. The zinc layer does not allow the metal to rust, and such a profile lasts much longer. In any case, this is the best option that should be applied, despite its cost.

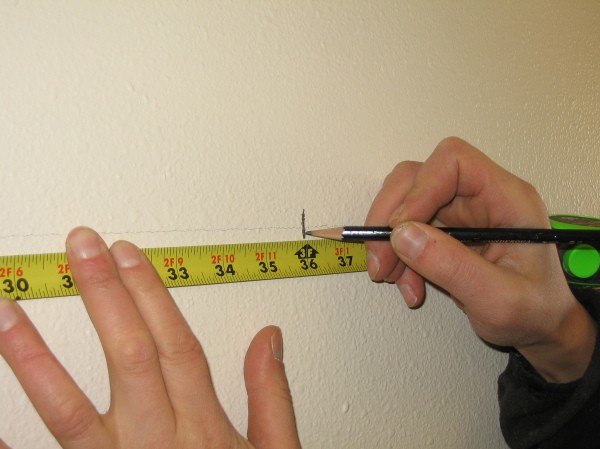

So, we decided on the material, and we can proceed directly to manufacturing. And first of all, you need to mark up.

It is important to observe the distance between the rails. It is necessary that it does not exceed 50 centimeters. Only in this way will your finish be reliable and durable.

First, plumb lines are attached to the wall, the distance between which should also be minimal, then, guide profiles are fixed to these suspensions. At this stage, it is important to observe the level of all guides. If there is a difference between them, then the finish will turn out to be uneven.

In principle, there is nothing complicated here, but for the sake of persuasion, we suggest you watch the video in this article, which shows the instructions for making a frame for gypsum board, and talks about how to sheathe the outer walls of gypsum board.

Installation

Compared to all previous stages, this is the simplest and fastest, but of course, provided that the frame was built smooth, without changes and kinks. Now it remains just to cut the drywall sheets to the size we need, and, applying them to the frame, fix them with self-tapping screws for metal.

As we said above, no holes for self-tapping screws are unnecessary to drill, they will independently break their way and pull the sheet to the base.

The most important thing is to get used to twisting. A self-tapping screw should be drowned in drywall so that its hat does not protrude above the surface, but at the same time, it should not be buried too deep. In this case, the self-tapping screw will destroy the gypsum, and the fasteners will not work.

Before you start work, we recommend that you practice on a small segment, and only after your hand gets used to the tool, take up the finish.

Well, that’s basically it. As you can see, there is nothing complicated here, the main thing is to strictly follow all the recommendations and not neglect any of the points given in this article, and then, your decoration will last for many years and you won’t have to redo it or restore it.