Facing the ceiling with drywall: do it right

Facing the ceiling and walls with drywall is quite common in the decoration of the room and is popular. If you decide to apply this material, then this article is for you.

Facing ceilings with drywall is not such a difficult job and it is quite possible to do it yourself, which will significantly reduce the cost of all work. You will have the opportunity to see photos and videos on this topic, below will be given instructions for performing this work.

The content of the article

Advantages and disadvantages of drywall finishing

Despite the fact that people often use drywall in the decoration, it also has drawbacks. Therefore, before making a purchase of material, you should familiarize yourself with its positive and negative sides.

So:

- With this form ceiling finishes you don’t need to worry about the evenness of the base plane. It will be enough to prepare and protect it from the onset of disease;

- Facing with plasterboard ceiling will close communications and this is especially true for old buildings;

- Lining the walls and ceiling with drywall can also be done with the use of insulation. This will reduce heat loss and strengthen the soundproofing of the room;

- Facing ceilings with plasterboard sheets makes it possible to install spotlights without problems. You can highlight the desired area of the room by lighting;

- With this finish you can select almost any element of the room. There is always the possibility of installing a multi-level system where you can make an abasement and hide, for example, a pipe;

- All work can be completely done with your own hands and without outside help. If you need to support the sheets, then your family can do it. Work is expensive and you will save a lot on this;

- The price of the material is not high and almost anyone can make such a finish. If an estimate is made, you will see for yourself that this is not an expensive pleasure;

- There is a significant drawback, it is that you reduce the useful area of the room. At least five cm. The fact is that the sheets are attached to the frame and therefore this cannot be avoided;

- It should be remembered that attaching drywall is not the end of the job. You still need to do the finishing, this should also be attributed to the shortcomings;

Attention: The material is afraid of direct water ingress, therefore, when installing in the bathroom, you should use a waterproof material and do a treatment that will protect the plane from water and extend the life of the entire structure.

Choose material

This material is of several types. They are excellent in place of use.

And before installation, you should decide which one is most suitable for your premises, and purchase it:

- GCR, this is the simplest drywall, which is most often used. It is gray in color and it is mounted in rooms with heating;

- GKLO is a fire-resistant material. Its composition uses materials that allow it to withstand elevated temperatures and at the same time not change the structure.

Such material can withstand 20 minutes of direct exposure to fire without problems. It has a gray color and red marking; - GKLV is a moisture resistant material that can withstand high humidity. It can be perfectly applied to decorate the bathroom. It is issued green has blue marking;

- GKLVO, it is both fireproof and moisture resistant material at the same time. It has green color with red marking.

Drywall Installation

Facing walls and ceilings drywall is not so difficult, but a job that requires the right approach. It is carried out in several stages.

The most important thing is to take them seriously. After all, improper execution, even minimally, can lead to big trouble.

Do not forget that the sheets should be brought to the installation site in advance and put them on a flat surface and pressed with a load. They should level out and gain the necessary humidity and get used to the temperature.

Surface preparation and marking

To start, you should correctly prepare the base plane, so that you do not get any troubles later. Fungus and mold may appear and this should be avoided.

So:

- We do inspect the plane. After that, take a brush for metal and remove the old coating;

- We look at the exfoliation of plaster and cracks. We are not interested in small ones, but if there are large cracks and delaminations.

Then you should simply putty the large recesses and remove the peeling with a chisel and hammer; - Now we process the plane with the help of antiseptics, which are available on the market. To do this, use a brush or spray;

- After complete drying, cover the plane with a primer;

Now, after a quality surface preparation, we need to mark the installation of the ceiling. This is a crucial question.

If it is not solved correctly, then you will get an irregular geometric shape in the end result:

- We put the risk on the wall where the installation is planned plasterboard ceiling;

Attention: if you plan to mount the insulation, then this size should also be considered.

And it should be noted that after installing the sheets, the material should not be deformed, otherwise it will lose its properties. It is necessary to provide a gap of a couple cm.

- Now we need to transfer this risk to other walls and this must be done correctly. To do this, it is worth using the hydraulic level, which is worth buying or making yourself. We transfer the size and put marks;

- After that, we need to combine the risks. To do this, take a kapron thread and just beat off the line. Now we have the level of flow fixation.

Frame installation

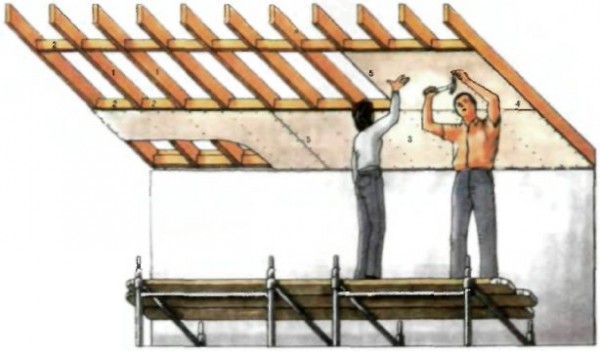

Facing walls and ceilings with drywall begins precisely with the installation of the frame, it will hold the weight of the entire structure and therefore it should be performed quite qualitatively. It will largely determine the appearance, if the plane is not made correctly, then the sheets will repeat the contour and the result will be the wrong configuration.

As a material for the frame, you can use a metal corner or wood.

Attention: If you have chosen the second option, then you should bring the material in advance and do the processing of the bars using antiseptics. They are available for sale and this will significantly extend the life of the entire structure.

- We cut the slats to the desired size and do the fastening strictly along the line. If the wall is made of wood, then simple self-tapping screws will do.

If you have a plane made of concrete or brick, then you have to make holes with a punch and make the connection on the dowels;

Attention: At us the framework should hold rather rigidly.

Therefore, do not use the dowel from the sets. Buy separately plastic dummies and self-tapping screws for them, only their diameter should be a couple of mm larger from the cross section of the plastic hole.

- Nailed the slats around the perimeter. Now we need to mount the transverse rails.

This should be done in one plane. To do this, pull the fishing line along the diagonal of the room and mount it as described above.

Height adjustment is done using gaskets. The distance between the rails should not exceed 50 t. We carry out the installation of rails on the entire plane; - When marking the transverse elements, the following should be considered: they should be perpendicular to the sheet and be at a distance of not more than 50 cm from each other;

- Now the insulation is fastened.

Do the cabling

After installing the frame, we need to make a wiring for lighting.

This work is performed in the following order:

- First, find the place to connect the cable. This should be the point where you can easily reach.

This will be needed in case of breakdown. Here we fix the junction box;

Attention: You should immediately think about what kind of fixtures you will use.

Just if it is energy-saving, then you will need to install a step-down transformer. It should then be put where the junction box is.

- Now we bring the cables and fasten them. We make connections with the help of terminal blocks with their help it will be of the highest quality.

Avoid using twists, this can only do harm. All cables must be secured securely to protect themselves.

In the places of output of lighting devices, we release the cable so that you can freely connect the lighting device. It is free and without stretch; - After that, we connect the lighting devices and turn on the current. We look at the correct distribution of lighting.

So far, everything can be fixed without problems. After installing the sheets, you will have to redo everything. Therefore, be sure to check. If everything suits, then turn off the power and remove the lights.

Sheet fastening

Now we have come to the end of this phase of work. We need to make a lining.

This work is carried out according to certain rules, which we give:

- Facing with plasterboard ceilings starts from the corner of the room from the window. It is here that the lighting is distributed in the highest quality and you can see all the installation errors and troubleshoot;

- All sheet joints are made on a solid surface of the frame, and not on weight. Consider this when attaching the frame;

- The sheet before installation is first applied and we look at the correct installation. After that, it is worth immediately chamfering the edges of the elements and then make the connection.

Fastening is done with screws using a distance of not more than 20 cm from each other;

Attention: It should be said about the attachment points, it may be necessary to mount it much more often. All edges should be firmly pressed to the surface.

- The screw is screwed completely and with a decrease of a couple of mm from the plane of the sheet. After that, when finishing, these pits are simply putty.

Its fastening is carried out strictly perpendicularly. If it went wrong, then you should not make the connection in the same place, you should step back a couple of cm and make the connection in a new way; - The sheet should not touch the wall and fit against each other. It is necessary to make a gap of the order of 5 mm.

You will need this to avoid trouble when expanding the material; - You will have to cut the material, this is as follows. At first, the sheet should be tried on dry and mark the points of attachment.

After that, remove it and draw a line using a straight rail. Now we place the sheet on an even plane and, after attaching the rail, we make an incision with a sharp knife.

Laying on the table is best; it is best suited for this. After the cut, we shift the sheet by 5 mm relative to the edge of the table and apply a rail along the cut line.

The field of this we do a sharp pressure on another part. The sheet breaks exactly along the notch line; - You will need to make holes for the fixtures. This is done as follows.

We attach the sheet to the installation site and mark the output point of the lamp. After that, remove it and put it on an even plane.

We make a hole with a drill and nozzle. After that we do fastening and we deduce wires; - Thus, we make a full finish of the entire plane.

Do the finishing

Now we need to spend drywall ceiling.

To do this, use dry mixes with which the surface is completely leveled:

- We start the start in the tank for kneading, it is best to use the tank without stiffeners and make the kneading with a drill with a nozzle. It is in this way that we will ensure the uniformity of the entire mass;

- Apply the mixture to the plane with a wide spatula. At the first stage, beauty is not so important to us as it is necessary to make a surface in one plane. We pass on the surface;

- We are waiting for complete drying. Now we are making the finish kneading.

With its help, finishing is done. Now we apply this material to the plane. We are waiting for complete drying;

Attention: At the joints of sheets should immediately attach and a sickle. It will strengthen the connection and make the plane more durable and durable.

- Now we begin to grind with a grater and a construction grid. This is done in a circular motion.

We just need to draw a plane. Where there are sinks, immediately after processing it should be puttied with a finish. After drying, carry out the treatment again.

And we do this until we get a perfectly flat surface. First we have to do a grid processing with a large cell. After full alignment, you should go over the grid with the smallest cell.

Work is done. Now you can apply a primer that will hide minor scratches and then paint. The most important thing is not to rush and do everything right, starting with the markup.