How to sew up a wall with drywall in accordance with all the rules

How to sew drywall wall? This is of interest to home owners who want to make repairs in a short time without big labor and significant financial resources. Using gypsum plasterboard (gypsum plasterboard), it is possible to level the surface, the material is a good basis for applying decorative finishes.

How to wall the walls are sutured with drywall, the article will tell.

The content of the article

Drywall Features

Drywall is designed to simplify the surface finishing process.

Using it you can:

- Correct the errors that occurred during the construction of the house.

- Mask uneven corners.

- Hide communication systems.

In addition to this material:

- Practical.

- It has a low price.

- Eco-friendly.

- It can be painted, tiled, wallpapered.

Read also:

- Drywall sheets allow you to equip a variety of volumetric structures, such as:

- multi-level ceilings;

- light septum.

- The space between the drywall and the wall can be filled with insulating material.

- Sheets are well processed by any tools, they are easy:

- are cut;

- sawed;

- drilled;

- mounted.

Before you sew up walls with drywall, you must mount a special frame.

How to build a drywall frame from profiles

To mount the frame with your own hands you need to purchase:

- Guide UD profiles.

- Rack CD profiles.

- U-shaped direct suspensions.

- "Crabs" or sibling connections.

- Self-tapping screws 3 x 9.5 mm.

- Dowels, dimensions 6 x 40 mm.

In addition, you need to prepare:

- Building level.

- Plumb line.

- Convenient roulette.

- Chalk for marking.

- Electric shock drill.

- Screwdriver.

- Knife.

Work Instructions:

- Marked surfaces. For this:

- Using the building level or plumb, the most protruding sections on the wall are determined;

- marks in these places are transferred to the floor;

- to obtain a rectangular room, a straight line is drawn through one of the marks so that it is the outline of the rectangle, the remaining marks must be placed between this line and the wall.

Tip: To align the wall, you must draw a line between the most prominent marks.

- a second line is drawn, parallel to the first, departing from it 5 millimeters, to which the width of the “U” -shaped profile is added. This line is needed to mount the profile;

- the second line is transferred to the ceiling using a plumb line.

- Mounted around the perimeter “U” -shaped metal profile. For this:

- profiles of the necessary length are cut;

- the elements are mounted on the walls, floor and ceiling with dowels and yellow screws for quick installation;

- to walls made of wood and adobe, as well as to wooden ceilings and floors, the profile can be fixed with ordinary “black” screws.

Further:

- holes are drilled in the profile with a diameter of 7 millimeters in increments of 50 centimeters;

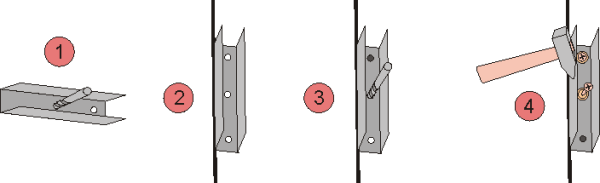

- the part is attached to the wall, ceiling or floor so that its front part is on the line marked earlier, in the photo position 2;

- with a pencil or marker marks the points of holes drilled in the profile;

- holes in the wall are drilled with a puncher or an electric drill with a solid drill, position 3;

- profile is fixed to the wall, ceiling or floor with dowels and screws, which can be for quick installation or the most ordinary ones, position 4.

Tip: If there is a large curvature on the wall, floor or ceiling, the profile bends during fixation and takes the form of a wave at the attachment points. To remove this phenomenon, the part should be carefully cut with metal scissors from above and below.

- Mounted the main frame for drywall from "C" - shaped profile.

Elements of the frame for drywall must be located in places:

- Joints GKL.

- Door and window openings.

- Niche locations.

Usually one profile is installed at the junction of the sheets, with a standard width of 1.2 meters, and intermediate through 60 centimeters. Below are sample profile mounting schemes:

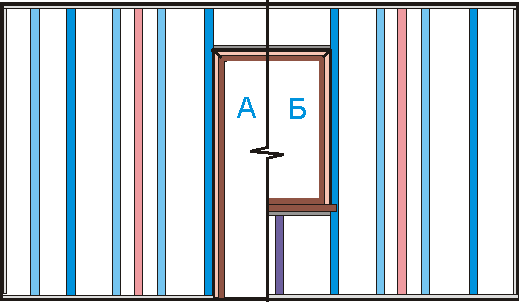

In the diagram:

- A is the doorway.

- B - window opening.

- The “U” -shaped profile is shown in gray.

- “C” - shaped profiles are blue.

- Intermediate C-profiles with a pitch of 40 centimeters are blue.

- At a step of 60 centimeters - orange.

- An intermediate C-profile in violet is shown with a window opening.

Tip: You should not install intermediate profiles above the window opening, with a window width of up to three meters, if the distance to the ceiling from the top of the slope is up to 50 centimeters.

So:

- All elements are fastened with dowels for quick installation.

- The CD profile is trimmed. Its length should be approximately 8 millimeters less than the distance between the walls. At this distance of more than three meters, the parts are connected by brackets.

- In the UD profile, the CD element is set slightly at an angle.

- The CD profile is fixed to the wall mounts with self-tapping screws or rivets.

Tip: The frame should be done in stages, no more than for two sheets of drywall, then you should attach the sheets of drywall and mount the frame further, which will avoid alterations that arise due to measurement errors.

How to mount drywall panels

After installing the frame, the wall is sutured with drywall. With the correct installation of the crate (seeLet's consider how to fix a profile for drywall to a wall) standard sheets of material fit perfectly. A construction knife is used to trim the excess pieces.

For this:

- A deep incision is made on the sheet under the ruler.

- Drywall is cracked and cardboard is cut with a knife on the other side.

- Sandpaper processes the edge of the sheet, which should be slightly beveled, to facilitate the filling of joints between sheets of material after installation.

To install GKL, you will need:

- Knife.

- Sandpaper or peeling plane.

- With countersunk heads, self-tapping screws - 3 x 25 millimeters.

- The ruler is long.

- Pencil.

Laying rules:

- Applied to the GCR frame.

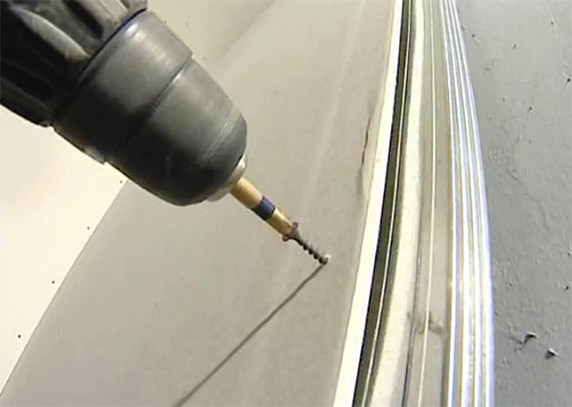

- Screws are screwed around the perimeter of the sheet with a step of 15 centimeters, and in the intermediate profiles in the center of the panel, the step of the screws is taken 25 centimeters.

- From the edge of the drywall to the first self-tapping screw, the distance should be at least one centimeter.

- In the corners of the panel, fasteners are placed from an angle of at least 5 centimeters.

- The screws are screwed perpendicular to the profile, while the screws' heads are slightly recessed into the gypsum board without breaking through the outer layer of the cardboard. If by chance the self-tapping screw fell into a void or was simply inserted incorrectly, it must be removed and screwed in again, 5 cm away from the previous installation site.

After installing drywall, the walls are putty (seeHow to putty drywall - basic rules and techniques).

For this:

- All joints, arising recesses, gusts, mounting locations are primed.

- A serpian is glued at the seams.

- All of the above places are putty.

- After the putty dries, the entire surface of the drywall is primed.

- Another layer of putty is applied.

- After solidification, the surface is cleaned with sandpaper.

How to mount drywall directly on the wall

It is more correct to attach the GCR to the frame. But you can sew drywall to the wall.The secret of this installation is to use special glue to fix the panels, which is based on gypsum and polymers. This technology is called - dry plaster without profiles.

Tip: GKL, glued to a wall without a profile, can not be used for wooden walls, however, if the wall is made of gas blocks, this is the only possible option - drilling aerated concrete under the anchor for attaching the frame is very difficult.

Briefly how to sew drywall to the wall, can be described as follows:

- The wall is cleaned of existing old plaster

- The surface is primed in two layers.

- It is dried out.

- The gaps between the gypsum wall and the ceiling is up to 5 millimeters, and the floor is up to one centimeter.

- Nails are driven into the upper corner, and then into the lower corner.

- A thread is stretched between them, at 90 ° to the floor, which is controlled by a plumb line.

- Similar actions are performed from the opposite side.

- The nails are joined with a thread to make a perfect line.

- In the resulting square, the unevenness of the wall is determined.

- If there are defects more than 2 centimeters, a substrate is prepared from pieces of drywall 10 centimeters wide, and are mounted vertically.

- Marking is made on the wall for cutting a sheet.

- If the panels are short, the pieces increase in a checkerboard pattern: to the floor - to the ceiling. In this case, it is necessary to take into account the open places where the pipe or other objects exit.

- To install the beacons, horizontal threads are pulled in increments of 50 centimeters.

- The geometry of the GKL installation is controlled by the level and plumb.

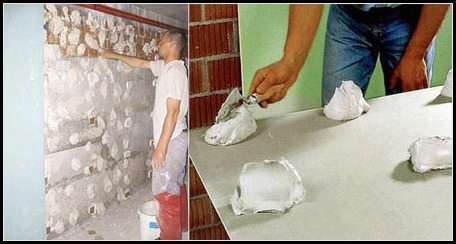

- On each thread, glue or beacon cakes with a diameter of 7 centimeters are applied with the same step.

- Grind on a thread, controlled by level.

After the glue dries, the drywall sheets are mounted:

- Panels are cut to the desired size, so that the edges with a recess correspond to vertical seams.

- Lines for a vertical joint are selected long, and for a horizontal connection - short.

- Drywall installation on the prepared wall is made from the bottom corner, moving to the ceiling, and then to the side.

- To set the gap between the floor and the panels, the first sheet is installed on the wedges.

- On the perimeter, the adhesive is applied with a notched trowel, 5 centimeters in steps of 40 centimeters from the edge of the sheet. Glue is a supporting structure, it should be distributed evenly.

- When the wall relief exceeds the teeth of the spatula, the adhesive is applied with "cakes" with a step of 40 centimeters stepping back from the edge.

- The gap between the plates should be 3-5 millimeters.

- A rule is applied to the sheet, the surface is leveled by tapping with a rubber mallet.

Further, all operations are similar for frame installation of gypsum plasterboard. All options for wall decoration with drywall are shown in the video in this article.

When installing drywall sheets directly on the wall, one of the important advantages of drywall finishing is lost, namely, the ability to remove communications under it. If under the drywall, sewn onto the frame from the profile, the wiring is laid comfortably and hidden, then when gluing the sheets, you have to choose from two not very convenient options.Either remove the wiring in the hay, and then stick drywall - but then the wiring will be difficult to access, or ditch through the sheathing sheets - but then the main advantage of such a finish is lost - its perfectly flat and monolithic surface. It seems to me that the frame is still more correct.