Let's consider how to fix a profile for drywall to a wall

Installation of the profile under the drywall on the wall is necessary for reliable fixation of the sheets. Drywall can be attached to wooden slats, glued directly to the wall. But this is used when it is impossible, due to some reason, to apply a drywall profile for metal walls. How to do it right, the article will tell.

The content of the article

Features of drywall sheets

Gypsum plasterboards or gypsum plasterboard are used in many areas during repair and construction works, such as:

- Creating arches (see How to beautifully finish a plasterboard arch).

- Alignment of the planes of walls and ceilings.

- Creation of multi-level ceilings.

- Formation of built-in closets and niches.

- Decorative finish.

- The design of the facades.

- Repair inside a building with high humidity, such as a bathroom (see Plasterboard bathroom decoration: work procedure).

The classic version of drywall is a sheet made by pressing, with a core of gypsum and cardboard for cladding. Drywall is classified by purpose.

He can be:

- Stenov. It is made in white and gray, 12.5 millimeters thick. Their price is less than other types of drywall sheets. Used for:

- repair and installation of walls or interior partitions;

- creating niches;

- manufacturing shelves;

- design of suspended structures.

- Ceiling mounted. It has a smaller thickness, not more than 9.5 millimeters, which greatly facilitates the mounted structure. Used by:

- for covering the ceiling;

- to create multi-level structures;

- when creating arches and other curved structures.

- Arched. It has the smallest thickness of similar materials, not more than 6.5 millimeters. It is used to create various radius structures of different curvatures.

- Moisture resistant. It is marked as GKLV, external sheets are painted green. The material almost does not absorb moisture, so it is used in the decoration of the bathroom, toilets and other rooms where the humidity is high.

- Fire resistant. GKLO has a red surface. It features a reinforced internal structure, which gives the material resistance to fire and high temperature.

- Façade. Drywall sheets are coated on both sides with fiberglass. Their standard thickness is 12.5 millimeters, the surface is painted bright yellow.

- With insulation. It is a modification of a standard sheet to which a polystyrene block is attached with glue. The thickness of the insulation layer can be up to 60 millimeters, the walls finished with them have the highest insulation parameters.

- Coated from vinyl. This is a modern solution with increased versatility of the finishing material. There is a decorated vinyl cover on one side of the sheet. When delivered, the GKL kit includes universal profiles and elements of the same color for joining sheets, which allows the installation of walls with ready-made color solutions.

Drywall sheets can be:

- Width over 60 centimeters.

- The length is over 2.5 meters.

Features of drywall sheets also determine the different way of fixing them with your own hands.

Which profile can be fixed drywall

For ease of installation, you can use the profile for the wall of drywall, which is of four types:

- Two of them are used for mounting the frame on the walls and for the manufacture of partitions.

- Two - for the device frame on the ceiling.

The standard length of the elements is three or four meters. The thickness of the metal used for their manufacture is from 0.4 to 0.8 millimeters. The best option for a profile thickness of at least 0.55 millimeters. In addition, two types of elements are used for finishing plasterboard surfaces.

By purpose, profiles are:

- Rack or PS. They have a C-shape with longitudinal grooves. The base of the element is a “back”, its width varies between 50-100 millimeters, and the sides are “shelves”, their size is always 50 millimeters, they are used for the installation of partitions and claddings. It is used when mounting uprights.

- Guides or Mon. U-shaped with dimensions:

- 40 millimeters shelf width, always constant;

- from 50 to 100 millimeters, the size of the base.

They are used to create partitions and wall frames. During installation, it is fixed to the ceiling and floor, creating a rigid frame for the main structure.

- Ceiling or PP, with dimensions: 60x27 millimeters, have three identical longitudinal grooves. Used for the device of a suspended structure.

- Ceiling guides or PNP, their sizes: 28x27 millimeters. They are used for mounting frames on ceilings and as a vertical element for walls.

- Corner or PU, dimensions that are: 31x31, 25x25 millimeters. Used to strengthen corners. They are made external or internal, which differ in parameters and purpose.

- Arched or PA have a curved or convex shape. They are used to design doorways of arched type and create complex suspended structures of a wavy shape.

As additional elements are used:

- Coupling, to increase the length of the PP profiles.

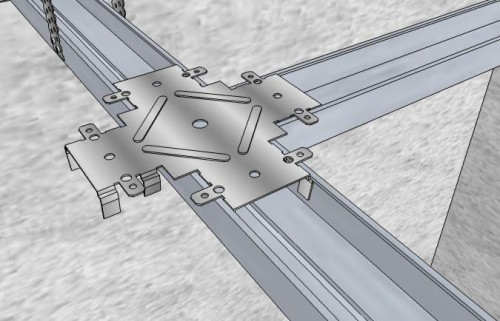

- The crab is made cross-shaped and is used at the intersection of the profile elements, as in the photo, which increases the strength of the structure. The two-level crab is mounted on the upper level PP and firmly fixes the metal profile of the lower level.

- The direct suspension element is attached to the surface, and bends along special lines. Then, profiles are installed and fixed in the U-shaped opening. Excess "ears" are gently bent or cut off.

Tip: When using such a fastener, it is necessary that the sub-ceiling space should be no more than 6 centimeters.

- Clips and rods of anchor suspensions. With their help, you can adjust the height of the inter-ceiling space in the range from 25 to 100 centimeters. The supporting part of the element provides a stable location of the PP.

How to choose hardware for mounting profiles

Hardware for fixing guides and suspensions should be selected on the type of surfaces for which they are intended.

For instance:

- For walls and ceilings made of concrete, the profile or suspensions are anchored with dowels, the dimensions of which are 6x60 or 6x40 millimeters, which depends on the quality of the surfaces.

- Screws with sizes of 6x70, 6x80 mm are used on the basis of wood for fasteners.

- All metal structural elements, such as: direct suspensions to ceiling profiles, rack-mount profiles to guides, couplings, crabs, it is better to fix between themselves with self-tapping screws with a pointed end, dimensions 3.5x11 millimeters.

- Drywall is attached to metal profiles with self-tapping screws with a fine thread 3.5 × 25 mm, made of galvanized steel. In this case, it is not worth pre-drilling any holes.

- The profile guides for the manufacture of racks to the ceiling from gypsum plasterboard can be fixed with special drop-down dowels, which provide reliable fastening.

What tools are needed when installing profile elements

The profile for drywall walls is mounted on:

- Direct suspensions.

- Anchor suspensions.

- Crab Connectors

To install the frame and lay the insulation, you will need to prepare:

- Puncher, for drilling holes for installing dowels.

- Screwdriver.

- Electric drill with a special nozzle for fixing drywall.

- Screwdriver.

- Scrapprofile or notch.

- Rasp.

- Jigsaw.

- Nippers.

- Building level with magnetic side.

- Water level.

- Laser level.

- Chockline or masking cord.

- Sinku.

- Plumb line.

- Metal or wooden square.

- Dowels and drills for them, with a diameter of 6 millimeters.

- Self-tapping screws, with a diameter of 4 millimeters.

- For cutting profile scissors for metal.

- Double-sided tape.

- Protective gloves.

- Mask to protect the face when working with insulation.

How to mount a profile on the ceiling

Tip: Before you purchase a metal profile for the installation of drywall, you should correctly calculate its amount.

For this:

- The dimensions of the room are measured.

- A profile arrangement is drawn taking into account the arrangement of the rack elements with a pitch of 40 or 60 centimeters, the dimensions are taken along the axes of the elements, provided that whole sheets of drywall are fixed to the frame. This is due to the fact that usually a sheet of drywall is made 1.2 meters wide, and it should be fastened to three, and preferably four rack-mount parts. In this case, the joints of the drywall sheets should be located in the middle of the profile, in order to subsequently avoid the formation of cracks on the wall.

After acquiring materials and tools, you can begin to work.

Tip: When planning the decoration of the entire room, the work must begin with the device frame on the ceiling. Very often, its surface deviates from an angle of 90 °. If at the same time you begin to perform work from the walls, it will be quite difficult to adjust the drywall panels at the top.

Further, the procedure is as follows:

- Electrical work is being carried out, a cable is being supplied to the locations of the lighting fixtures. In this case, the length of the wire is taken with a margin of up to 15 centimeters.

- The performance of all wiring connections is checked. When installing spotlights, the passage of metal structural elements is carefully planned.

- Determines how far the new ceiling will descend. In this case, the installation of spotlights should be taken into account, you will need to know their height, which can range from 5 to 15 centimeters.

- A point is marked on the wall from which all markings will be made. Using the laser level, a horizontal line is drawn with a pencil or upholstery cord.

- The tape measure measures the required length of the part and is cut with metal scissors. Profiles can be easily joined by inserting one end to the other, with an overlap of at least 30 millimeters, then this point is fixed with the corresponding fastener.

- On the lines laid in advance on the walls, the PNP is mounted through the existing working holes on the profile, if they are absent, they are drilled with a pitch of half a meter with a perforator or electric drill, which depends on the base of the wall on which the frame is mounted.

- Marking is performed to fix the ceiling profiles. For this:

- about 60 centimeters need to retreat from the wall, due to the roughness of the walls;

- the level checks the accuracy of the location of the notches;

- the profile, which is used as a ruler, combines the risks on opposite walls - this line will be the "point" of reference;

- parallel to it, with a step of 60 centimeters, lines are drawn over the entire area of the ceiling.

- In the same way, the ceiling is marked along the length of the room.

- Direct suspensions are fixed with dowels with a step of 60 centimeters, the center of their base should be placed on a marked line. At the points of installation of devices or equipment, it is better to additionally install traverses.

Tip: It is not necessary to procure for future use; ceiling profiles for the installation of drywall are not necessary; the distance between the walls at different points in the room can differ significantly. For each profile, the length should be measured separately, and its value should be less than about 2 centimeters than the width of the room.

- Ceiling profiles are installed in the rails so that the central groove is at risk. Their position is fixed with one self-tapping screw. If necessary, a clutch is used.

- 60 cm long jumpers are cut from the ceiling profile with scissors for metal, and the cross-pieces that will be needed to install from the wall to the first longitudinal element are two centimeters shorter than the existing distance.

- In the process, it is necessary to control the coincidence of the profile groove and the marks on the walls.

- In places where the transverse element is connected with the longitudinal, a single-level "crab" is used, and is attached with self-tapping screws.

- Ceiling profiles are attached to the suspensions. Wherein:

- to PP, a level is assigned to each connection point;

- after checking all places, the deviations are adjusted;

- All elements are securely fixed.

- Drywall sheets are mounted.

How to mount a metal profile on a wall

Tip: Before mounting the wall frame from a metal profile, all work related to electricity is performed: wires are supplied to the switches, sockets, points of location of lighting devices, all household appliances.

The technology of mounting the wall frame is to finish each wall separately.

The instruction for attaching the frame to the walls from the profile for drywall offers the following procedure:

- Particular attention is required when installing the frame of the wall with windows. If you need to insulate the walls, vertical profiles are installed at a distance of 50 millimeters from the old slopes.

- The width of the windowsill has an effect, when decorating the walls after installation, the layout of the frame starts from the window. But at the same time, the thickness of the drywall sheet must be taken into account, it can be 12.5 or 9.5 millimeters.

- A square is applied to the frame and the desired distance is measured, adding 5 centimeters on the other side of the opening. You can immediately install the PN to the “bottom” of the windowsill, with a step of vertical racks up to 60 centimeters.

- The construction level is applied to the risks, which will help to transfer them to the side planes of the windowsill.

- The marks on the floor and ceiling are connected.

- The profile guides are installed along these lines:

- on the sides of the window, the verticals in this case are marked from these profiles in increments of 60 centimeters;

- one of them must be installed in the corner of the room.

- Suspensions are mounted with a step of 60 centimeters, with the center strictly along the line.

- The rails are installed in the rails so that their middle groove coincides with the mark on the floor and ceiling, and then are connected to each other.

- The level adjusts the vertical elements on the shelves and the base.

- The final fastening is carried out with self-tapping screws.

- The crossbars are fixed with the help of a “crab”. A horizontal jumper is installed above the opening.

- After fully fixing the metal frame to the wall, you need to sketch the placement of transverse and longitudinal profiles. This scheme will be required if there is a need to place paintings, an additional shelf, or fastenings to the ceiling of a decorative planter on the wall.

- In this case, the so-called “umbrellas”, “butterflies” and other similar elements are used for fastening, which are fastened according to this principle: when the screw is screwed in, the plastic dowel spreads its “wings”, which ensures reliable fastening from the back of the drywall sheet.

How wall sheathing is done with drywall on wooden profiles, the video in this article will show in detail.If all installation work is carried out correctly, the decoration of the room with gypsum plasterboards will be of good quality.

Drywall can be used not only as a decoration. but also as a structural material. Plasterboard partitions mounted on the profile, lightweight durable, perfectly even. The space between the sheets, filled with mineral wool or polystyrene foam, excellent heat and sound insulation.