Gypsum board cladding: frame cladding and adhesive alignment

Much has been said about giprock as a finishing material. But this topic seems inexhaustible because the internal gypsum plasterboard lining allows not only to smooth the surfaces, but also to make the room completely unusual.

There are many ways to achieve this: changing the configuration of the room, creating ceiling structures, installing decorative partitions, arches and working niches. In this article we will tell you how to make gypsum plasterboard cladding with your own hands, and in what ways you can perform this work.

The content of the article

Drywall Work: General Information

Facing gypsum plasterboard surfaces is also called dry leveling, since this material has long been called “dry plaster”. Qualitatively plastering the walls, not having the skills and experience, not everyone can, even after seeing how the specialists work.

Whether it is the GKL case: a little instruction - and you can do this work yourself.

Tools and Supplies

If you are determined to learn how to work with drywall, you will have to purchase a complete list of necessary tools. Screwdrivers, a hammer, a hammer drill and a screwdriver are in almost every home.

But special tools will be required:

- First of all, it is a knife for cutting drywall, or a cutter, a knife saw and two types of planers: peeling and edging. With the help of these tools, sheets are cut, holes are cut out in them and edges are machined. It is more convenient to cut curved lines with a jigsaw.

- If not just facing the surface with plasterboard sheets, but performing figured structures, a needle roller will be needed.

- When installing the frame from an aluminum profile, a cutter and scissors for metal will be needed. Profile for plasterboard cladding standard is used: PPN 28x27 (directing) and software 60x27 (wall).

- In the case when the lining is made on a wooden crate, a 20 * 40 rail is used, and if the surface is insulated - bars 30x30 or 40x40.

The frame is fixed to the base with dowels, and the sheets are mounted to the crate with self-tapping screws. If it comes to ceilings, you will need direct suspensions. - To install the frame, you must have a square, a building level, a plumb line, a dyeing thread. Since drywall needs to be finished, you will need: wide and narrow spatulas, abrasive mesh or sandpaper, reinforcing tape, gypsum putty and acrylic primer.

To apply the soil composition, you need a brush-brush, roller and a plastic bath.

About what types of GCR exist, how to cut, bend, and also process edges correctly, you can familiarize yourself by watching videos, which are many on the Internet.

Mounting the frame from the profile

The choice of this or that type of lathing is carried out based on how large the irregularities have surfaces. If they are insignificant, a rake will do.

Significant differences are easier to correct with the help of a profile system:

- In any case, if the room is being renovated, the surfaces are cleaned of the old decorative coating. As for the old plaster: it is possible to clean only in those places where it crumbles, or you have to remove it completely if it is easily separated from the base.

Relatively durable plaster layer does not need to be touched. If you sheathe walls in a new building - they do not need preparation at all. - Next, markup is made, according to which the installation of the crate elements will be carried out. If it is planned to build partitions, it is first necessary to mark the location points of the bearing profiles on the floor, after which, using a plumb line, the marks are transferred to the walls and ceiling.

- First, a guide profile is mounted along the lower and upper perimeter of the wall. The places where it adjoins the floor and ceiling should be treated with silicone sealant, but you can just stick on the sealing tape.

The rack profile is mounted with a step of 60 cm. This number is a multiple of the sizes of many types of modular facing materials, including gypsum plaster. - Each profile must be attached to the wall with dowels, in increments of one meter. If the profile is shorter than three meters, it should still be fixed in at least three places.

Given the thermal expansion of materials, when docking the profile along the length, a small gap must be left between the ends. - The guide and rack profiles are interconnected by a notch with a bend - for this, a notch is used. Rack profiles should not rest against the ceiling, but should be at least a centimeter lower - this is not a floor slab, but the level of the suspended ceiling, if any.

- In any case, the suspended ceiling is mounted first. Its installation is carried out similarly, only direct suspensions are used here, allowing you to set the suspension plane at an arbitrarily remote distance from the base surface.

- Drywall wall cladding It is made after the ceiling structure is completely ready, with the exception of the finish. In more detail with the process of creating suspended and false ceilings from gyro, you can find in the articles on this topic, which are on our website.

- After installing the frame, all electrical work should be done: replacing the wiring, transferring switches or sockets, wiring for lighting and lighting.

Advice! In no case do not lay the wires inside the profiles, because you can damage them during the process of hanging drywall sheets on the frame.

- If such cladding is done in a private house, it is very likely that wall insulation will also be performed. In this case, at the end of the electrical installation, a heater is laid in the cells of the frame.

- The frame for the partition must be voluminous, and its installation is somewhat different from the lathing for the cladding. First, one side of the frame is mounted, then the second.

Bearing (rack) profiles, in this case, do not fasten to the walls, but wedge between the floor and the ceiling. The guide profile is mounted in the same way as in the case of wall cladding.

- As a rule, in the partition there is doorway, which is framed by supporting profiles. To strengthen the structure, wooden bars are inserted inside the profiles along the perimeter of the opening: they will help to hold the door, which will be installed later.

- The door frame is attached to the racks immediately, during the construction of the partition. Depending on its design, a jumper from the guide profile is mounted above the opening, and intermediate racks are installed above it.

At the intersection of the partition, or wall cladding with utilities, it is necessary to install sleeves on the pipes.

- After the frame is ready, the doorway is first lined with plasterboard sheets, and then the entire plane of the partition is sheathed. It is worth saying that for working partitions it is better to use gypsum fiber sheets.

They have higher strength, and are able to withstand considerable loads. - The price of such sheets is higher than that of GCR, but gypsum fiber sheets provide structures with maximum rigidity. And this is of great importance, especially if working niches are provided in the partition, which are often used to install household appliances.

For covering the load-bearing walls, creating decorative partitions and ceiling structures, standard sheets of drywall are usually used. - So, after, on the one hand, the lining of the partitions with plasterboard sheets is completed, their space is filled with mineral wool or polystyrene plates. In this case, they will play the role of sound insulation.

If the width of the plates is one centimeter less than the step of the crate, they will fit tightly into the cells of the frame and will not require additional fixation.

- At this stage, inside the partition, you can lay the cables for the Internet and the phone, the wires for the backlight, mount the electrical boxes for drywall, in which the switches or sockets will be located. If there is an opening in the partition, the slope is first lined with drywall, and then the second side of the structure is sheathed.

- Turning your attention to the frame method of leveling the walls, you can ask the following question: “How can the rather fragile surface of the gyro board withstand the loads from the wall cabinets?” The question is fair, and there is a worthy solution to such a problem.

- Simply, in the place where it is planned to hang the cabinets, gypsum board lining in 2 layers is performed. There is no particular difference in these technologies: the pitch of the crate belts is slightly reduced (it will not be 60 cm, but 40 cm), and the sheets need to be glued together, and not just fixed with screws.

There is gypsum glue on sale, which you will need for this purpose. Cutting holes for communications is done before the sheets are glued.

Installation and finishing GKL

The size of a standard GKL sheet is 2.5 x 1.2 meters, and with a thickness of 9 mm it weighs about 9 kg. For this reason, it is inconvenient for one person to work with such bulky material, especially if you will sheathe the ceiling as well.

So you need at least one helper:

- If during installation of the frame you strictly followed the step of the crate belts, installation of the sheets will not create problems - their edges will definitely fall in the middle of the profile. Sheets are fastened with screws to the profile, trying not to sink their heads into the thickness of the gyroc. The pitch of the fasteners should be within 15-17 cm.

- The sheets are arranged so that the edge sections form a groove, which will then be filled with gypsum putty.

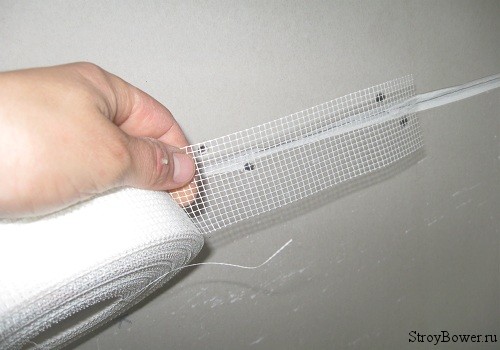

It strengthens the seam and makes it invisible fiberglass tape or, as it is also called - sickle. Although, with the same success, they use paper tape with a rough surface. - The tape is glued in the center of the joint, after it has been treated with a primer. All corner joints are glued.

Then, the seam is filled with a putty mixture, its excess is removed, and the surface is leveled so that the tape is not visible. - Putty need and self-tapping heads. Before sealing, run a spatula over the place where the screw is screwed. If its head clings to a spatula, the screw must be tightened.

- We saw that it was excessively sunk into the sheet, and the cardboard cover was torn - remove the mount, and make a new one at a distance of 5 cm. Only then can the primers and primers be primed.

- If, as a finishing finish, gluing drywall is made with wallpaper with a good relief and density, then such preparation of the drywall surface, as in the photo above, will be quite enough. For painting, you have to putty the entire surface completely.

- Speaking of leveling the walls with the help of GCR, one can not help saying that this can be done in another way. This is gypsum plasterboard lining on glue.

You can use this method if the base surface of the walls does not have large flaws and drops, as well as in small rooms, the area of which does not allow the use of frame cladding. - By the way, in this way, most often, facing the slopes of drywall. This method involves the installation and fastening of GKL sheets to the wall on a mounting foam.

This technology is as follows: GKL is applied to the wall, and it is drilled directly on it so that there is a mark for fasteners on the wall. Each sheet should have up to ten attachment points. - Then the sheet is removed, normal holes are drilled according to the marks, and chopped under the screws are inserted into them. Pieces of foam rubber are glued onto a sheet of gyrocock, at some distance from the holes, which during installation will play the role of a shock absorber.

- Fasten the sheet by placing small washers under the screws that will not allow them to fall through and break the cardboard cover. The position of the sheet must be adjusted using the building level.

- When all sheets are mounted, holes with a diameter of 5-6 mm are drilled near each mount. Through these holes, the space under the hygroc will be filled with foam.

After it dries, the screws and washers are unscrewed, the holes and joints are putty in the same way as when installing gypsum plaster on the frame. - As an option, gypsum-based dry adhesive mixture is used for the installation of drywall sheets, for example Perlfix from the well-known manufacturer Knauf. It is bred according to the instructions, the consistency of the finished glue is quite thick.

The mixture is spotted both on the wall and on the gypsum board, after which it is pressed to the base and adjusted with a rubber mallet. The smaller the sheet, the more convenient it is to glue it.

No need to suffer, trying to stick large sheets, you can cut them, for example, into four parts. For placing a complex configuration, such as in the picture above, the adhesive method of facing with a hydrocom is most acceptable.