Plasterboard wall covering in a wooden house: several secrets of high-quality repair

Repair and drywall have long been inseparable concepts. Without the second, the first rarely happens, but not always working with drywall is simple and convenient. We are now talking about the owners of wooden houses, which during the repair process may encounter problems that are alien to the decoration of brick walls.

In this article, we will talk about how gypsum plasterboard wall cladding occurs in a wooden house, and describe the two most affordable ways that you can do it yourself.

The content of the article

Features of repair in a wooden house

So, what difficulties can lie in wait when repairing in a wooden house? First of all, it is the inevitable seasonal deformation of the walls. The tree itself has the ability to slightly change shape when the temperature or humidity level changes, so this factor must be taken into account without fail.

Based on this feature, the gluing installation method, which is considered the simplest when working with drywall in brick buildings, does not suit us at all. A tight mount leaves no room for deformation, and the drywall will bend along with the walls, and this will inevitably lead to its destruction.

But not only the deformation factor is distinguished by the installation of drywall on wooden walls. An equally important factor is the increased humidity of the surface, which can not only destroy drywall, but also lead to the formation of mold spores, which quickly grows under the finish and can cause significant harm to health.

Frameless mounting

As we said above, gluing drywall onto wooden walls will not work. But this does not mean that it is impossible to carry out installation without the construction of the crate. It is possible, only as fasteners we will use dowels with a plastic sleeve, which simply clog into the wall and expand inside, due to which the fastening takes place.

This method is very simple and its price is especially pleasing to many. Indeed, in this case, you do not have to spend money on materials for the frame and time on its construction. Unfortunately, there are a number of limitations due to which this method is not always applicable. There are quite a few limitations, but we will focus on the most significant of them.

Limitations

So:

- If your wall freezes in the winter, then this method of fastening will not work. The wall will get wet even more. And even moisture-proof drywall will not cope with such increased humidity.

- If large communications, such as heating pipes, water pipes or ventilation systems, pass along your wall, you will either have to redo them and move them away from the wall, or consider another installation method.

- The curvature of the walls exceeds 2 centimeters. In this case, the surface will have to be leveled, but it is much easier to abandon this installation method.

As you can see, there are a lot of situations when plasterboard sheathing of wooden walls without a frame is impossible. And that is why this method is not considered the most common, although it is the simplest.

If you have not met a single item from your list in your home, then consider yourself lucky, and you can use this option, and in this case, let's consider this process more carefully.

Advice! Do not save on the type of drywall. Today on sale there are special sheets marked GKLVO. This is a non-combustible, moisture-resistant drywall with increased strength. The difference in price will be small, but such walls will last much longer.

Installation

Sheathing of wooden walls with drywall without a frame begins with a thorough surface preparation. In our situation, the quality of the entire repair will depend on it.

So, the installation consists of several stages:

- We remove the old finish and clean the surface of dust, dirt and grease stains.

- Ground the walls impregnations with antiseptics that prevent the appearance of mold and fungus (seePrimer for wood and the rules for its selection).

- Let the tree dry and apply another layer of soil. The more there are, the better. Saving is not the place.

- Cut the sheets to size, given the small gaps from the bottom and top. 3-5 millimeters is enough. They are necessary to compensate for possible wall deformations, then the drywall will have free space for curvature and it will not burst.

- We put wedges on the floor for a gap, and lean the sheet of drywall, starting from a convenient angle for you.

- We drill a hole in the center of the sheet and hammer the dowel into it until it stops.

- Drill new holes horizontally and vertically in all directions in increments of approximately 30 centimeters. Also, we hammer fasteners around the perimeter of the sheet.

- Check the sheet for installation strength and when finding a weak spot, we make additional fortifications.

Here, in principle, that's all, in the same way we put all the other sheets and at the end we close the joints between them using a special reinforcing mesh and putty (seeHow to putty drywall joints according to technology).

Important! Drive the dowel very carefully. One extra blow, and the dowel head will break through the cardboard layer, and such fasteners will have to be redone, as over time it will simply stop holding the sheet.

Frame mounting

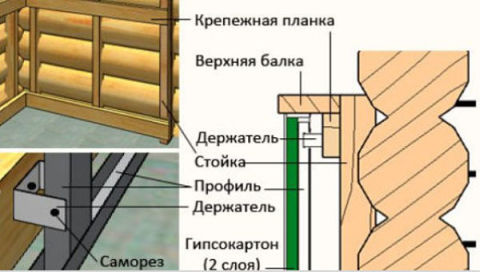

With this method, before sheeting the walls with drywall in a wooden house, a special crate is first built on them, which serves as the basis for fastening the sheets.

The best option for building a frame in this situation can be considered a wooden beam (seeDo-it-yourself installation of a frame for drywall on a wall), although in cases with brick walls, experts try to refuse to use it. It's all about the same deformation and fragility of wood compared to metal, but since we have walls made of this material, it makes no sense to extend the life of the crate.

It is important to properly protect the tree, and here a special impregnation or water stain is suitable. They will not extend the service life of the bar insignificantly, but they will not allow bugs to get inside that sharpen the tree and destroy it.

The use of metal plumb lines can also be abandoned. It is much easier to fasten the block with the help of long black screws, and compensate for differences on the wall with the help of wooden wedges of different sizes.

Installation

So, first of all, we mark the wall. It is important that the distance between the guides does not exceed 50 centimeters, otherwise the sheet may sag or break in these places.It is desirable to set horizontal guides, but not necessarily, you can do without them.

When the markings are applied, we attach the first bar to the wall, and fasten it with a screwdriver and a self-tapping screw, guided by the testimony of the building level. Just note that a small difference of 2-3 millimeters is not critical, and it can be ignored, but more serious differences are eliminated by substituting wedges under the bar.

Important! Wood screws are distinguished by a wide pitch of carving. They hold the material much better and do not crash over time.

As you can see, the process is not complicated, but for a better understanding, we recommend that you watch the video in this article, which shows detailed instructions for arranging a frame from a wooden beam.

Summary

So, plasterboard walls in a wooden house are possible, and it’s better to still use the frame method of installation, since it has no restrictions, and seasonal deformation and humidity are completely unimportant to you.

And finally, I would like to note: before you plaster a wooden wall with plasterboard, or rather choose a method, carefully correlate all the pros and cons. Do not immediately choose the simpler and less time-consuming first method. As practice shows, such walls serve much less, and in the process of operation a number of problems can arise, which can only be solved by completely redoing the repair. And this is costly both in finance and in time.