Gypsum plasterboard cladding: finishes

Facing walls with plasterboard sheets on frames is now used in almost any repair work. You can mount such material as drywall, not only on the wall, but also on the ceiling.

The content of the article

- Possibilities of using plasterboard sheets on the frame

- Drywall Benefits

- In which rooms can you use drywall

- Frame for mounting drywall on the wall surface

- How is the metal frame for the installation of drywall made

- Installation of drywall sheets on the frame

- Wooden frames for the installation of drywall sheets

Possibilities of using plasterboard sheets on the frame

Drywall is used when it is necessary to level the surface or build any structure in a short period of time. For example, a multilevel ceiling or arch (seeHow to beautifully finish a plasterboard arch).

But for all works with drywall there is a certain type of material:

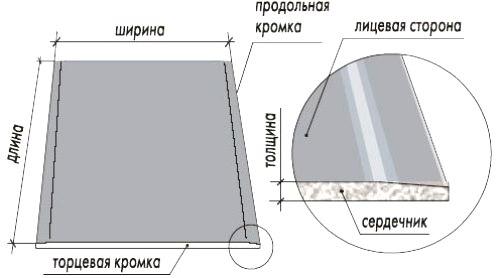

- Ceiling drywall is used for the manufacture of ceiling structures and leveling the ceiling surface. It is very light and does not exceed 0.5-0.8 mm in thickness.

- Arched drywall is intended only for the manufacture of decorative arches of any complexity. It is quite simple to work with it, as the material is very flexible and able to take any form.

- Wall gypsocraton is used only for leveling wall surfaces. It has a greater thickness and mass than the ceiling.

It is much better in strength than the ceiling, as it is designed for significant mechanical and physical effects. - There is also fireproof and moisture resistant drywall, which is used on any surface, depending on the needs.

Tip. If electrical communications will pass under the sheets of drywall, it is best to choose a fireproof drywall and all work on their laying is carried out only before the installation of the material.

Drywall Benefits

The main advantage of drywall is the acceleration of surface leveling. It is mounted on any type of surface using a frame.

Drywall Properties:

- The material is very durable, especially wall, but it is necessary to work with it extremely carefully, since gypsum dough can break its structure when it is hit or accidentally dropped.

- It has a simple installation scheme, as this will not require any skills in this area and all work is done by hand.

- Long-lasting, as it does not have a specific period of use. With proper use, it will last for 20-25 years.

- The practicality of the material is quite high, since drywall sheets have a simple and quick installation, and also do not require specific care after installation.

- Withstands high loads on its surface. Whole kitchen sets can be mounted on the drywall wall.

The price for it is not too high, which makes it more popular.

In which rooms can you use drywall

There are no restrictions for the use of drywall, since there are various types of it. You can apply it in the kitchen area, in the bathroom, living room and even in the nursery.

Tip. In the bathroom it is necessary to use only moisture-proof drywall on the frame, as this type of room is characterized by high humidity.

Features:

- Regardless of the finishing method, moisture will collect under the drywall, which will eventually lead to the formation of mold or various other fungal diseases. To prevent this from happening, it is worth considering the advice of professionals.

- On sheets of drywall, you can apply paint or wallpaper, only their surface must first be prepared.

- A number of such works include puttying the joints of sheets of material and their further processing with sandpaper. After that, they are primed and only then subjected to final processing.

The photo shows examples of finishing plasterboard sheets on the frame.

Frame for mounting drywall on the wall surface

Wall covering plasterboard sheets on the frame is quite simple.

For this, two types of frame are used:

- Metal.

- Wood.

Each of them is distinguished by its manufacturing method and its technical properties.

Frame for mounting drywall made of metal

Plasterboard cladding on a metal frame is considered more professional than on a wooden structure. This is due to the fact that there are special metal profiles that are designed specifically for the installation of sheets of material.

Characteristics:

- The metal profile frame is durable. There are several types of guide profiles that are used for its manufacture on the surface.

You can use it on any surface, as it is attached to it with dowels. - The metal frame is very practical. Its manufacture is not too complicated, and everyone can cope with all types of work. The period of use of the frame is long, since it does not corrode and is not affected by a humid environment, like a wooden frame.

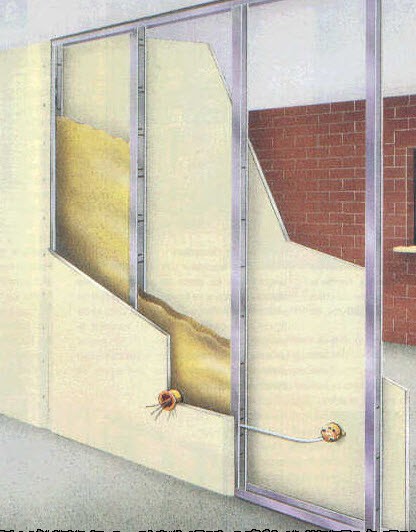

- The metal frame for plasterboard cladding has a small weight, which will not create additional load on the walls of the building. Also on its basis there is an opportunity to build interior partitions.

In this case, the frame is closed on both sides and insulation material is laid between the sheets, which will provide sound insulation.

The metal frame for plasterboard cladding consists of two types of profiles:

- Rack profiles.

- Guides.

More details:

- Rack profiles are metal structures that have a U-shape with curved ends. These edges serve as amplifiers of the strength and reliability of the metal structure for the installation of drywall sheets.

- This type of profiles is fastened only in an upright position. On its sides, om has certain recesses for laying various kinds of communications.

The dimensions of the rack profile can be:

- 50x70 mm.

- 75x50 mm.

- 100x50 mm.

So:

- Their choice depends on the size of the material itself, since large profiles are used for high-grade drywall sheets, and small ones for cut or simply smaller sizes.

- Wall cladding with drywall on a metal frame can not do without guide profiles. They are U-shaped metal structures.

Curved endings of the side walls, in contrast to the rack, they do not have. - There are profile guides that already on their surface have certain holes for their installation. There are those that go whole and hole drilling happens on their own.

Tip. In the latter case, it is worth considering that the holes for mounting the drywall frame should be located at a distance of no more than 50 cm from each other.

The size of the guide profile can be:

- 50x40 mm.

- 75x40 mm.

- 100x40 mm.

The guide metal profiles are mounted in a horizontal position and serve as the basis for the installation of sewage structures. They can be attached both to the ceiling of the room and to the floor.

How is the metal frame for the installation of drywall made

Facing walls with drywall on a metal frame begins with the manufacture of the frame itself on the surface.

To do this, you will need:

- Rack profiles.

- Guide profiles.

Tip. The choice of their size largely depends on the size and thickness of the drywall sheets themselves.

- Dowels for fixing profiles to the surface.

- Punch for screwing dowels.

- Self-tapping screws for fastening profiles to each other.

- Screwdriver for screwing in screws.

- Construction level for smoother installation of profiles on the surface.

- Scissors or a hacksaw for cutting profiles.

Work Stages:

- The profile guides are immediately mounted, into which rack-mounted then are mounted. Both those and those are attached to the main surface with dowels. Rack profiles are fixed to each other at the base of the guide profile using metal screws and a screwdriver.

- In some cases, the entire structure may be made of guide profiles. Only of them should be made box, which has sufficient strength to withstand the load of drywall sheets.

They are mounted in the same way.

The video shows an example of the manufacture of a metal frame on the surface.

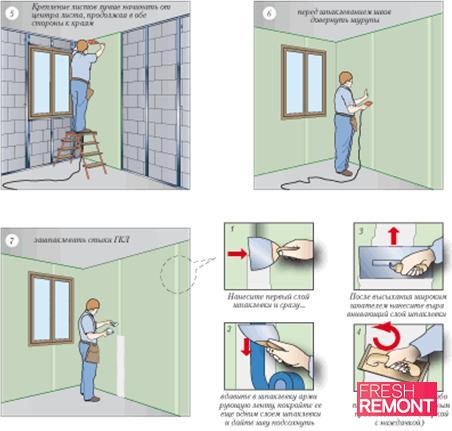

Installation of drywall sheets on the frame

Cladding of plasterboard sheets on a metal frame is quite quick and easy.

For work you will need:

- Building level.

- Stationery knife for cutting drywall sheets.

- Self-tapping screws (there are special ones for installing drywall, which have elongated legs, and very quickly fix the material on the surface of the profile).

- Screwdriver for screwing in screws. Instead, you can use a drill or a simple screwdriver. The last version of the tool is able to greatly complicate and increase the entire process in time.

Work:

- There is no special instruction for this, since everything is intuitively clear even to a specialist in this field.

- Facing the walls with plasterboard sheets on the frame requires further decoration, as the joints of the material will be visible. For such work, plaster or putty is used, with which the compounds are processed.

Tip. For a better application of the putty solution on the joints of the drywall sheets, it is best to glue a special paper tape on them and put the putty on it already.

After drying of such a solution, all places are processed with sandpaper and only after that it is possible to carry out finishing work on the surface of the drywall, since it has a not very attractive appearance.

Wooden frames for the installation of drywall sheets

This method of installing drywall is rarely used. This is due to the practicality of wood.

It is able to respond to various temperature changes.

The wood frame in its appearance resembles a crate for installing plastic or siding. There is nothing complicated in its manufacture, but after such work it will be necessary to paint it or prime it to protect it from exposure to a humid environment and other adverse effects.