Plasterboard ceilings and walls: tips from the master

Plasterboard walls and ceilings are in high demand. It is perfect for any room.

Plasterboard walls and ceilings will far surpass other materials. Therefore, this article will tell you how to properly implement it.

The content of the article

Advantages of plasterboard finishing

This material has a number of qualities that are not subject to doubt:

- This is a completely environmental material that does not harm human health. Its installation can be done in any type of room.

It has several types and therefore it is worth choosing the right type of room for the right one; - You will not be interested in the unevenness of the walls, such material will perfectly cover any irregularities, you only need to make the correct preparation of the base plane;

- You can always do immediately and the insulation of walls and ceiling. Moreover, a layer of insulation can be applied any. To do this, just select the profile of the appropriate height;

- You can hide unnecessary communications and make installation in several tiers;

- This material will serve as an excellent basis for further finishing, which can be done with any material.

Attention: Before starting work, you must correctly select the sheet brand. But remember, even moisture-resistant material should not be installed, for example, in a bathhouse. He still drinks water and becomes worthless. But it’s perfect for the bathroom.

- There is a significant drawback, you will pick up the usable area in the room. Sheets are mounted mainly on the frame and it can be at least five cm high.

It is thanks to the qualities described above drywall finish The walls and ceiling inside residential and office space has become quite common.

Types of installation of drywall

Among the whole variety of interiors that are made of drywall sheets, the technology of its installation is reduced to two types:

- Installation using a frame (from a metal profile or a wooden beam).

- Without the use of frame crates.

Each of these types of installation has its own characteristics, which we will consider below.

Gypsum plasterboard cladding

Most often, GKL sheets are attached to a special crate - a frame.

It can be made of metal profiles, which have different sizes depending on the purpose. Less commonly used is a wooden beam.

Attention: Over time, the wooden beam absorbs moisture and begins to deform, which leads to damage to the surfaces.

Therefore, if you want to use the beam as a crate, then do this only in dry rooms. After the purchase, it must be treated with antiseptics that are in retail. This will significantly extend the life of the entire structure.

Why do I need a frame for drywall:

- It allows you to perfectly level the surface in front of the fastening of GKL sheets on the walls and ceiling. This is especially true for rooms where these surfaces often have a large curvature.

- Thanks to the use of the crate, it becomes possible to hide various communications in the appeared space: ventilation, cables, pipes, heating radiators.

- You can perform wall insulation by placing a heater between the main wall and the frame.

- You can dream up a bit and create an unusual interior at home and will finish in several tiers;

Attention: In this design, the quality of the installation of the frame is quite important. It must be firmly held and at the same time it is necessary to maintain the correct geometric shape of the structure.

Otherwise, the sheets of material will not lie correctly. Therefore, when installing, use a meter continuously.

To determine the level of fastening, it is best to use a hydraulic level, which will make this work qualitatively.

How is it made ceiling decoration and walls with drywall using a frame? To do this, first of all, we need 2 types of profiles (guide and rack), suspensions for the profile, tools, fasteners and drywall itself.

The following is a brief instruction on the wireframe paneling method for GKL sheets:

- To get started, put a mark on the wall and indicate the level of the ceiling. And after that we transfer the size to other walls using the hydraulic level;

- Now we need to connect the marks, this is done with the help of a kapron thread and just beat off the fastening line;

- After marking, we attach the guides to the surfaces: to concrete or brick with a dowel with a screw, having previously drilled holes for the dowel; to wooden surfaces;

Attention: The design is not light in weight and therefore the fastening should be performed with high quality. Do not use dowels from sets.

Obtain separately plastic and self-tapping screws to it. And a couple of cm more from the section of the hole in the plastic. Such a connection will be quite reliable and high quality.

- We got a contour around the perimeter of the room, which means finding the level of the plane. Now we pull the fishing line along the diagonals of the room. It will then be quite simple for us to adjust the height of the transverse profile;

- Now we cut the transverse guides to the desired size and fasten them as described above. When marking fasteners, the length of the sheet should be taken into account.

Joining sheets should only be done on a hard surface, not on weight. The distance between the profile should be no more than 50 tism. Height adjustment is done using gaskets;

- For height adjustment, direct suspensions for racks 60x27 mm can also be used. They are attached to the surface and to the ends of the profile.

The interval between them is 300-500 mm. It depends on the thickness of the drywall used for installation and the total weight of the entire structure.

Attention: It can be said that the decoration of walls and ceiling with drywall at the stage of mounting the frame is one of the most crucial moments. Therefore, we must take it very seriously and do not forget about the accuracy, which is checked by the level.

- The next stage is the fastening of GKL sheets to the prepared frame. For fasteners we use self-tapping screws;

Sheet Installation

Fastening sheets is not such a difficult task, but it is performed according to some principles and rules:

Caution: Before mounting, make the correct wiring and check that the light distribution is correct. Otherwise, after fastening the sheets, this will not be possible. Remember that junction boxes must be freely available. You will need it in case of breakdowns.

- Facing always starts from the corner and from the side of the window. It is here that the lighting quality drops and you can immediately see all the errors;

- Installation of sheets is not done in tight against the wall and to each other. This will protect you from troubles during temperature extremes and expansion of the material;

- When attaching the sheet, it should fit snugly to the surface of the profile without cracks and gaps. Watch for this. Before installation, remove the chamfer on the elements, it will be blocked by a subsequent finish;

- If the self-tapping screw does not go at a right angle, never mount in the same place.Step back a couple of cm from it and make a connection.

Moreover, the hat should be immersed in a plane for a couple of mm. To do this, you can simply make an outrage; - Never start fastening a sheet without first trying it on;

- Fastening is done in such a way that the joint lines are not in one line. The most commonly used chess order;

Drywall fasteners without using a frame

This method can only be used when the maximum curvature of the wall surface is not large. In this case, the repair price will be reduced, since there is no need to purchase a metal profile, components for it and additional hardware.

Of course, the options for such a correct execution of the wall are quite small and this option is rarely used, but this happens and we decided to tell how it is done.

Consider the step-by-step instructions for frameless mounting drywall on the wall:

- Surface preparation. For GKL fasteners, special glue is used.

In order for him to grip the glued surface as firmly as possible, it must be dry, degreased and saturated with a primer, there should be no residual paint and wallpaper on it. It is also necessary to prime the side of the sheet that will stick to the wall.

Do it in a quality manner, the service life of the coating will depend on it; - Preparing glue and applying it to drywall and the wall. The glue is best mixed in a plastic container with a nozzle on a drill in the form of a mixer.

Then it is applied with a notched trowel to the wall and GCR.

- We connect the glued surfaces. In this case, the possibility of sheet elongation due to changes in environmental conditions should be taken into account.

Therefore, do not cut the sheets close to the floor and ceiling - leave 10 mm on each side. Until the glue is seized, you can use linings.

Attention: No need to immediately stir a large amount of glue, since it quickly loses its properties - after 40 minutes. Therefore, do the kneading on the basis that you will develop it within half an hour.

- If necessary, trim the drywall "in place" you can use a rubber mallet. Tapping on the sheet should be neat!

Before starting work, it is advisable to place the material on a flat surface and press it with a load. In a couple of days it will have a perfectly even appearance and then the work process will be much easier; - After the glue has dried, for safety, the glued gypsum board should be fixed to the wall with dowels-nails. We drill a hole and carefully drive the dowel-nail into it until it stops.

Try not to damage the surface of the sheet. The frequency of fasteners is 400-500 mm around the perimeter of the sheets.

Finishing work

After we got a flat surface, wall and ceiling decoration drywall goes to the stage of finishing work.

It consists of the following steps:

- Sealing joints between sheets of gypsum plaster.

- Putty of the entire surface.

- Drawing a decorative layer: painting, gluing.

Stitching

For filling the joints, a gypsum-based putty mixture is used. The mixture is diluted with water, mixed with a spatula or mixer.

It should be borne in mind that any gypsum mortar quickly hardens. Therefore, do not breed it too much.

Attention: Before puttying it is necessary to process the joints with a deep penetration primer (GP) and wait for it to dry completely. This will greatly enhance the adhesion of surfaces.

So:

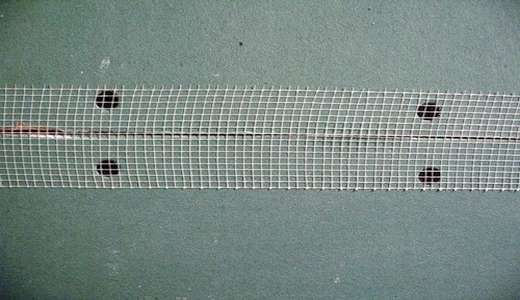

- When performing putty joints, it is best to use a perforated tape, which will qualitatively protect the joint. It can be plastic or metal. You can apply any.

- Putty is applied with a wide spatula. First, starting material is applied.

Moreover, at this stage, beauty should not bother much. You just draw the plane.

After it hardens, you need to do the processing of the plane with a building mesh. And first, a large cell is taken; - After that, the same coating is done with the finishing material. We are waiting for complete drying and do the same.

We achieve the complete disappearance of shells. After that, we do the processing with a mesh with the smallest cross section and can be primed and painted.

Decoration of plasterboard walls and ceilings

Drywall decoration of walls and ceilings allows the use of various coatings as a decorative layer:

- Paints on water dispersion. By default, the paint is white and can be diluted with color.

Paint is applied by roller or spray gun. In corners and inaccessible places you can use a soft brush. - PVC sheet panels. They are glued on putty on liquid nails or glue such as "Titan".

- Sheet decorative panels based on fiberboard. They are also fastened with glue from the "Liquid Nails" class. When buying, pay attention to the glue suitable for fiberboard.

- Wallpaper: paper, on a non-woven or fiberglass basis, natural wallpaper (usually from bamboo). For each type of wallpaper there is an “own” type of glue.

- Ceramic tile. It is glued to a special tile adhesive.

Finally, we want to give advice: decorating the walls and ceiling with sheets of drywall allows you to not only get even and smooth walls, but also to make a truly beautiful design in repair. Search the Internet for various photos and videos on this topic by typing in the search bar the phrase “interior design from hl”.

Look at these materials and, using the knowledge gained from this article, make the neighbors envy your imagination and ability to turn housing into luxury apartments.))

It should also be said that you can make a multi-level system. Only in this case, everything should be calculated correctly.

Here, the frame will already be much more complicated and therefore do not rush. Take measurements efficiently and try on each element.