Facing walls with drywall: do it sequentially

Facing the wall with drywall is perhaps the second option after plastering. It is indispensable for some work on leveling walls and hiding communications.

Regardless of whether plasterboard lining is made of wooden walls or consisting of any other material, it is performed according to certain rules and according to technology. In this article we will tell you how to clad walls with drywall according to the correct technology.

Before starting work, you should find out how this finish differs from other types. It is likely that you will change your mind after acquaintance.

The content of the article

Advantages and disadvantages of wall decoration with drywall

Facing with drywall walls has its positive and negative sides. Before buying material, you should familiarize yourself with them.

So:

- Inner wall cladding with a drywall perfectly aligns the base plane. Moreover, minimal surface preparation is required;

- You can completely hide all communications. If they are located in inconvenient places, then you can make additional boxes from this material and arrange them for interior items.

You can look at it on a photo and video; - If it is necessary to smooth out not strong irregularities, you can make drywall wall covering with glue. Although smooth walls are rare in our country, but there may be such a thing;

- Wall cladding with drywall allows you to immediately carry out wall insulation. And also make additional sound insulation;

- All work is carried out with environmentally friendly material that does not harm your health;

- Installation drywall It is fashionable to do it completely with your own hands, and without resorting to outside help. This will save you a lot of money;

- The price of the material is not high, it is much lower than many materials and almost anyone can afford it.

Attention: Of course, all this can be done, but first you need to choose the right drywall, which is divided into several types. And they are selected depending on the type of room.

Choose drywall

Cladding of wooden walls with drywall or others is done, this is not particularly important. You must first pick up the material that suits your room.

It is divided into several types:

- GCR, lining the inner wall with drywall of this type is most often found in everyday life. They can perform decoration of any type of premises.

It should only be taken into account that its installation is possible in a building with constant heating and without increased humidity. It has a gray color and blue markings; - GKLO, this material is already slightly different from the previous one, it is fire resistant and can withstand elevated temperatures. However, it is not suitable for use in a humid environment.

It is made in blue and red marking is applied; - GKLV, this material is moisture resistant and can be perfectly applied in the bathroom. Only for the sauna, it is not suitable.

It is good in moderation and it does not tolerate direct water. And this should be considered. It is green and has a blue marking; - GKLVO, gypsum plasterboard facing the internal walls with such material is not so common. Its price is higher than previous options.

It is just universal. Resists humid environments and elevated temperatures. It has green color and red marking.

We make the interior decoration of the walls with drywall

Facing the internal walls with drywall is done completely by yourself and without resorting to outside help. To do this, you do not need to study specifically, only you need to be able to use the tool that is in almost any household.

All work is divided into several stages, which should stop in more detail.

Surface preparation and marking

Facing walls with drywall begins precisely with this work. She will be the key to success.

Remember, almost everything is important here. Nothing to lose.

So:

- To begin with, you should remove all the old coating. To do this, use a brush for metal;

- We do a surface inspection. We are not interested in cracks and minor irregularities.

We look where there is a detachment of the plaster. If this is the case, then it should be removed with a chisel and hammer; - After that, we need to treat the surface with antiseptics. They are in free sale.

To do this, use a brush or spray;

Attention: Make the processing without fail. Even if there is no manifestation of the fungus.

It is even worth doing as a preventative measure. Otherwise, if the disease begins to appear after the installation of the cladding, then you will have to remove the entire coating;

- After processing, we wait for complete drying and apply a primer to the surface. To do this, use a brush or spray. We are waiting for complete drying;

- Now we need to apply the correct marking and indicate the level of fastening of the sheets. For this we use a plumb line.

We look at what height the sheets should be located. Make a mark on the ceiling and floor. Or two opposite walls;

Attention: if you use insulation, then you should know that it must be fixed as follows. Finishing material should not press and deform it. Otherwise, it loses its properties. Make a clearance of a couple cm.

- After this, the risks should be connected and this is done with the help of a kapron thread, it simply beats the size. Now we have a frame fastening loop.

Make the frame

The device for facing gypsum plasterboard walls consists in attaching sheets to the frame. If you are fastening directly along the wall, then it can be done in one layer and 2 layers, only if the wall allows and the deviations are not very large.

The frame is made of a metal profile or wooden beam. The second option should not be applied to the decoration of a damp room.

Attention: If you chose the second option, then it is worthwhile to draw a beam to the place of work in advance and make it processed with antiseptics. This will significantly increase the life of the entire structure.

So:

- We cut the slats to the desired size and fasten them along the drawn line. Connection with a wooden wall can also be done with self-tapping screws.

If it is concrete or brick, then you should first make holes with a punch and then connect to the dowels;

Attention: The design will have its own weight and must be firmly supported on the frame, so do not use the dowels from the sets. Obtain separately plastic and self-tapping screws to it.

Only take their diameter a couple cm less from the diameter of the plastic. Such fastening will be reliable and durable.

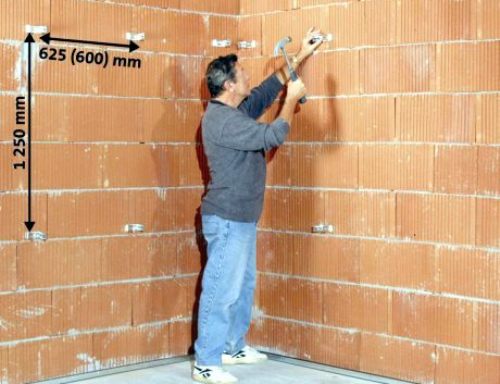

- After completing the strapping along the contour of the entire room, we need to fasten the transverse rails. They must be correctly adjusted for installation height.

To do this, pull the fishing line along the diagonal of the room. And navigate on it; - Do the markup. We trim the frame elements to the desired size. We carry out fastening;

Attention: When installing the frame, please note that it should not completely touch the wall. Make a gap of one cm. This will save you when the temperature changes. And remember that.

- After installing the frame, you can also fasten the insulation. It should not be deformed during installation and the mat is attached at least five points.

For this, building fungi are used. But before that, you need to put a layer of waterproofing, which should not be fastened right up to the rails of the frame, you cut the material taking into account the turn for a couple of cm.

Wiring installation

Facing the walls with drywall is done after installing the wiring for lighting. After all, lamps are also made, and it is necessary to install sockets.

The work is performed in the following order:

- We find a place to install a junction box. It is necessary that there be free access, this will be needed in case of a malfunction;

- Immediately consider whether you need a step-down transformer. Some make fixtures with energy-saving lamps. Here it is also worthwhile to install a step-down transformer;

- Now we make the fastening of the wires Before buying a cable, you should correctly calculate the load on it. It is not necessary to butt-in, a gap should be provided in the direction of an increase of 30%;

Attention; Make all connections with the help of terminal blocks, they will provide the highest quality connection. Avoid twisting, it is not reliable and dangerous.

- We do the wiring. If there are lamps, then they should be connected and check the correct distribution of light. After facing, this will be extremely costly.

Sheet Installation

This is not a difficult job, but it should be done in a certain order and correctly. The wizards give some advice on this subject and it is worth listening to them.

So:

- Fastening sheets should begin from the corner of the room and from the window. It is here that the most correct incidence of light will be and all errors will be immediately visible;

- The seam for joining sheets should not match. Mounting is mainly done in a checkerboard pattern;

- Material bonding is not done on weight. It runs only on the chassis.

And you don’t have to do tight fixings. Make a gap between the plates of 5 mm and then make the connection.

Make sure that the sheet fits snugly on the frame and fastens firmly; - The elements should be chamfered, then it will be easier for you to finish the finish and it will hold on much better;

- Self-tapping screws should be placed strictly vertically. If he went wrong, then he should not be thrashing to the same place. It is necessary to retreat a couple of cm and then make the connection in a new way;

- All hats should be hiding with respect to the surface for a couple of mm. It is necessary;

- The whole sheet will not always go in and will need to be cut. In this case, proceed as follows.

We put the sheet on the place of attachment and make marks on both sides. After that, we put it on a flat surface and connect the marks with a flat rail.

Now we are best suited for a flat table. We put a sheet on it and apply a rail, after that we cut it with an even knife.

No need to strive to cut it. Will not work. We simply mark the line of break.

After that, we shift it from the edge of the table by five mm and along the break line we put the rail and press it. We make a sharp pressure on the second part.

The sheet breaks exactly at the mark. After that, we clean the end with a plane and remove the chamfer; - You will also need to make round holes. Then cover the sheet and mark the hole.

After that, it is done with a drill and a crown, which must be purchased in advance. Do not make a sharp pressure. We do everything smoothly, otherwise the material will chip and it will be bitten;

Drywall wall decoration

This will be the last stage of the finish. For this, dry mixtures are used: start and finish.

So:

- First is the initial wall decoration. It is applied with a wide spatula and you do not really need to look so that there are no sinks.

At the first stage we need to designate the correct plane. We apply on the entire plane and wait for complete drying; - Now we take a construction grid and we begin to level a surface by rotational movements.We remove the excess. But we still have shells;

- We knead the finish and again apply it, but with a thinner layer. We are waiting for complete drying and again we pass along the surface with a mesh.

If it did not turn out smooth enough, then the finish should be applied again. And so do until complete alignment.

After the final finish, it remains for us to apply a primer and paint. As you can see, this is not such a difficult job. The main thing is to do it slowly and efficiently.