Gypsum plasterboard technology: installation methods

Various materials are used to level and finish wall surfaces. If drywall is used, the technology of wall cladding may be different.

At the moment, there are several options for fixing the material.

The content of the article

Why use drywall

Today, it is hardly possible to imagine any repair work that would be carried out without the use of drywall.

Advantageous characteristics of the material:

- Drywall - a universal material.

- It helps to quickly and easily level any surface.

- This is due to the fact that the material itself has a flat surface.

- It is produced in sheets of various sizes.

There are several types of raw materials that are most often used in repair work:

- Moisture resistant.

- Fire resistant.

- Usual.

The benefits also include:

- Durability, durability of drywall is at least 15 years.

- It does not harm health, as it consists of several layers: pressed cardboard, between the sheets of which there is gypsum dough.

Tip. Work with the material is quite neat, since gypsum dough easily breaks.

- Drywall is practical, and installation is simple and quick.

- It is worth noting that the price is affordable and it is several times cheaper to make the finish with drywall, rather than plaster.

- Moisture resistance and fire resistance of the material due to its types.

- The size of the drywall is 1.2x2.5 m. Thickness - 1.25 cm.

There is drywall:

- GKL.

- GKLV.

- GKLO.

Details on types:

- GCR is a simple sheet of drywall. It is used indoors for interior decoration. It is best used in rooms with a dry climate.

- GKLV more advanced material. It is moisture resistant and can be used in rooms with a humid environment.

- GKLO - fire-resistant drywall, which does not perceive the effects of fire and high temperatures.

Recommendations for use:

- Do not use drywall without external decoration.

- Be sure to perform its lining with any modern finishing material.

Drywall can be:

- Arched.

- Ceiling.

- Wall.

Note. All of them differ in sheet thickness and weight. The technology of facing with drywall of each type is not too different.

Methods of mounting drywall on the surface

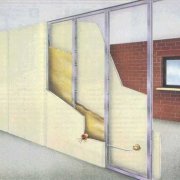

The technology of facing with drywall sheets involves the use of several methods:

- Fastening material to a wooden frame.

- Installation of drywall on the profile frame.

- Frameless sheet fasteners.

Tip. Drywall frame mounting is not recommended for use in a small area, as the usable area is taken.

Installation of drywall on a wooden crate

The oldest is technology plasterboard wall cladding on a wooden frame.

What this method provides:

- This method was used until a CD profile for mounting the material appeared.

- Also, this method began to be used for mounting plastic.

- This is due to the fact that wood has high quality indicators.

The advantages of wood:

- Durability and durability.

- Practicality and reliability.

Recommendations:

- The surface and structure of the wood is quite soft.

- For this reason, it is able to respond to a humid environment.

- Because of this, after the construction of the frame, it is necessary to cover it with paint or varnish.

- These actions will help to increase the period of use of the structure in important rooms.

On a wooden frame, the technology of wall cladding with plasterboard sheets is performed in a certain order:

- Surface cleansing.

- Padding.

- Mounting the frame.

- Fastening sheets of material.

From material and tools you will need:

- Wooden boards and planks of the same diameter and preferably square or rectangular in shape.

- Somoreza wood.

- Dowels for fixing the frame to the surface.

- Screwdriver.

- Plumb and construction level.

- Hammer drill.

- Saw or jigsaw.

- Putty and sandpaper.

The process of work:

- Initially, the old finish must be removed from the surface. It is especially necessary to pay attention to old plaster or paint, which over time tends to break off and crumble.

- All this is done with spatulas or a special paint remover.

- After that, the surface is checked for bumps using a plumb line or building level.

- Based on the data obtained, a routing is done wall cladding drywall.

What are gypsum plastering routings?

So:

- It calculates the required amount of material and wood.

- They are a cladding project.

- That is, thanks to such actions, you can see how the finish will look.

Important. If the surface is uneven, it is possible to use different parameters of wooden boards.

- After all such actions, a primer is performed on the surface, which will protect it from the appearance of various fungal diseases.

- Once the solution has been absorbed, you can proceed to the construction of the frame.

- It is worth noting that vertically mounted trims will be load-bearing. They are attached with dowels.

- Auxiliaries of a certain size are mounted to them. Such work is performed with wood screws and a screwdriver.

- To cut the material used a saw or jigsaw.

- Then, the finished frame is painted or varnished. The paint should dry well.

- After that, the installation of drywall sheets is carried out.

- It is carried out in whole sheets whenever possible.

- If you need to adjust the size, you can do this with a simple clerical knife.

- Sheets of material are attached using self-tapping screws for plasterboard sheets.

- Flush mounted material.

- Putty will be required after the installation is completed. She handles the joints of sheets. Once it has dried, it is treated with sandpaper so that the surface for the finish is smooth.

Tip. For fair facing of drywall, its surface is smeared with a primer.

Installation of drywall on a profile frame

Wall cladding with gypsum plasterboard technology based on the profile frame is more modern.

What does it provide for:

- Use special profiles for work.

- For work there is a special instruction, according to which all actions are performed.

The advantages of the profile frame:

- It consists of thin metal.

- According to their properties, metal profiles last longer than wood.

- They are moisture resistant and durable.

- Their practicality consists in simple installation.

- They do not burn and do not react to various temperature conditions.

Types of profiles for attaching the frame from profiles:

- Guide profile - designed to surface for future cladding. The length of this profile is 3 m, the width is 2.5 cm.

It can only be used for finishing wall surfaces. It can also be used for the construction of ceiling structures. - Bearing profiles - they are the basis of the frame for mounting the material. They distribute the entire load of the finish.

They are “responsible” for the rigidity of the crate and its reliability. Its length is also 3 m, and its width is 4 cm. - Rack profile - used to strengthen the frame and to specify the direction of the drywall sheets during installation.

- All other profiles are used for the ceiling and to create the arch.

Installation of metal profiles can be done with your own hands, for work you will need:

- The material itself and the drywall sheets.

- Self-tapping screws for metal and dowels.

- Construction level and hacksaw for metal.

- Rotary hammer and screwdriver.

- Putty and sandpaper.

Installation process:

- Rack and bearing profiles are mounted immediately on the surface.

- Guides are attached to them.

- The cell size of such a crate should be no more than 40-50 cm.

- Only in this way can sheets of gypsocarone be firmly attached.

- As soon as the frame is ready for it, drywall is attached. This is done using self-tapping screws, and the frame itself is mounted on the surface with dowels.

- Smooth installation of the structure is carried out using a building level, which can be replaced with a plumb line stretched from the corners of the room.

- After mounting the sheets, the joints of the material are processed with putty and sandpaper.

- Then the surface of the material is primed and it is ready for finishing. The video shows the whole process of attaching drywall to a metal frame from profiles.

- You also need to use metal mounts for mounting drywall sheets, see photo.

Frameless Drywall Mount

Frameless plasterboard cladding technology is quite popular in small rooms.

But for her there are several requirements:

- The surface must be well cleaned and primed.

- It should not have visible irregularities that would interfere with the installation of the material.

Consider this method in more detail:

- For work, simple drywall of any type is used.

- Instead of numerous fixtures, special glue is used.

- The frame is not required to be built.

- For this reason, this installation method is the simplest and fastest.

- An office knife is also used to cut the material.

The process of work:

- A project is being drawn up on the surface.

- The layout of each sheet is drawn.

- Sheets on the back are coated with special glue.

- Then they lean against the surface and fix for a while.

- The joints of the mounted sheets are coated with putty and processed after drying with sandpaper.

This technology of gypsum plasterboard wall cladding has one drawback - heavy objects cannot be attached to the surface of the material.

Tip. If you need to fix furniture on a wall that is made with drywall, it is best to use dowels and hooks that have long legs. This will make it possible to fix the structure directly to the brick wall, and not to the material.

Any method of attaching drywall sheets should be based on the size of the room and on its functionality.