Facing with gypsum plasterboard: do it right

Facing drywall with ceramic tiles is quite common. This work is not so difficult.

The main thing is to do it right. Here it is necessary to choose the right drywall and carry out the correct installation of tiles.

Facing with ceramic tiles on drywall is done after proper surface preparation. This will be discussed in our article.

First you need to purchase a tile and select the desired pattern. To do this, it is better to start to see photos and videos.

All work is done in several stages.

The content of the article

Finishing process

Cladding ceramic tiles drywall walls begins with correctly selected sheets and their fastening. If this is done poorly and the wall is not even, then the tile will not lie in the same plane and it will immediately catch your eye.

Rules for finishing with plasterboard for tiles

Facing the walls with ceramic tiles on drywall is done on a properly prepared surface. If you do not fulfill some requirements, then all the work will not last long, and it won’t look.

A well-prepared plane is the key to success:

- Make the correct markings first. The geometry of the finish will completely depend on this.

If on drywall this can be imperceptible, then the tile has faces and this is visible. And if the seam does not match, then it will immediately catch the eye; - Wall covering from gypsum board with ceramic tiles should be done on the correct material. After all, if ordinary sheets are attached in the bathroom, then over time they will gain moisture and warp and this will ruin the entire surface.

Therefore, for rooms with high humidity, it is worth choosing a moisture resistant material. - The frame for drywall must be mounted in the same plane. Otherwise, the material simply repeats its wrong contour.

Therefore, after tying the frame, you should pull the fishing line along the diagonals o adjust the height of the transverse profile fastening in height with the help of gaskets. And this must be done in a quality manner; - Do not fasten sheets tight to the surface of the walls. Make a gap of the order of one cm. This will save you from trouble when expanding the material.

Caution: Before attaching the frame, carefully prepare the reference plane. Do surface treatment with antiseptics. Otherwise, if a fungus appears later, then you have to dismantle everything.

Surface preparation

We have quality drywall attached, now for proper fastening you should prepare the surface in a high-quality manner. Facing walls with ceramic tiles on drywall begins with this.

Without high-quality processing and there will be no correct fastening:

- We do inspect the plane. We check the layer of the solution that will need to be applied.

To do this, it is worth pulling the fishing line along the diagonal of the plane and you will immediately see how much solution you need to apply; - We determine the number of seams. We need to putty the surface and place a perforated tape at the joints. It will strengthen the seam and make it better;

- Knead the solution.For this, a dry mixture is most often used, which should be passed through a sieve and all garbage should be separated and kneads should be kneaded;

- After that, we fill it in a container for mixing the solution. To do this, it is best to use containers without stiffeners at the edges and bottom. Then the kneading can be done in the highest quality;

- The dry mixture was poured and water was added. Now we need to mix it well.

The mass should be completely homogeneous and look like thick sour cream. To do this, it is best to use a drill with a nozzle.

Mix. If necessary, add water. The solution is ready; - Now we need to align the plane. After all, the solution is not applied in a large layer on the tile.

Therefore, we are not interested in roughness. We need a flat plane.

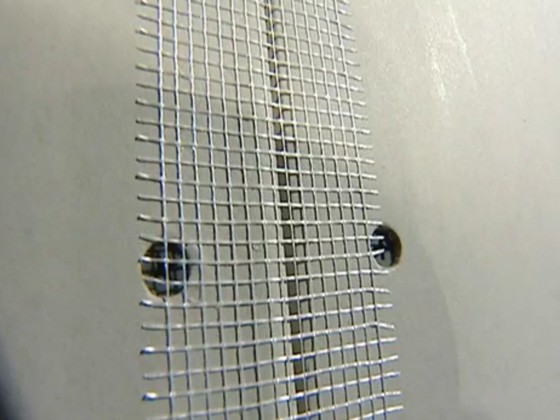

To do this, take a wide spatula and apply the solution on a plane. Not large sinks do not interest us. It is necessary to align the plane as a whole; - At the joints of the sheets we put a perforated tape and make putty on it. We are waiting for the complete drying of the surface;

- Slightly pass along the surface with a building mesh and knock down irregularities;

- Now apply a primer layer to the plane. To do this, use a brush or spray. Preference should be given to deep penetration liquids.

Tiling

Facing walls with ceramic tiles on drywall is not millet so, you need to take into account both the size of the room and the height of the ceiling. After all, the same option is not suitable everywhere.

For a small room

This option is suitable for small rooms. For example, in Khrushchev and the small family.

Here the selection is performed according to the following principle:

- The tile should not be large or mosaic;

- By shades, preference should be given to cold and light tones;

- By type of surface, gloss is best;

- For styling, it is best to choose the horizontal method;

- If you plan to use a pattern or frieze, then it is better to place it along the wall.

If the ceiling is not high

Here we need to make an increase in the room at least visually:

- For laying tiles we use the vertical method;

- We fix the ornament or frieze also in an upright position;

- For a corner bath it is best to use vertical columns;

- If we use decorative inserts, then we place them at eye level or higher.

Methods of fixing tiles

There are several ways to lay tiles. All work can be completely done with your own hands and without resorting to outside help.

This will significantly reduce the cost of the entire wall decoration. Instructions are given below. Let's get to know them better.

The basic way of fixing tiles

This is probably the most common option. Here the fastening is done simply in rows.

Before starting work, it is necessary to measure the material and decompose it not three packs according to size. The biggest one will turn out to be average, and the work should be started from it.

Attention: With this option of fastening it is necessary to do a quality placement. Here it is required to apply both plastic crosses and wedges.

We need to withstand the laying direction. It should also be noted that the last tile does not always completely fall into place.

They cut it. Therefore, initially correctly calculate. Maybe clipped elements are better placed on both sides of the row and make a specific pattern.

- Next, we correctly mark the first line of attachment. To do this, the craftsmen advise all tiles to be fixed in full size, and pruning should be done first row from the floor. We note the level of fasteners;

- To do this, put a mark and then transfer it to other walls. To do this, apply the hydraulic level.

It is available for sale or make it yourself. It is with his help that we will do it qualitatively. We transfer the markup; - Now connect the marks. To do this, we use kapron thread and just beat off the line.Now we have an initial installation level;

- We take a metal profile (or a wooden flat bar) and fasten it along the line. For the connection we use dowels.

The profile with us will serve as an emphasis and will not let the tile fall off below the level;

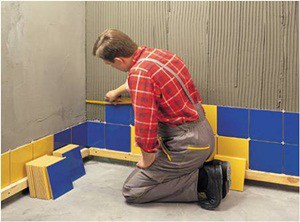

- We consider the correct distribution of the tiles and begin fastening;

- First, the tile should be tried on dry and see the correct placement;

- After that, if necessary, it is necessary to adjust the part. For this, a tile cutter or grinder is used;

- Now apply the solution to the surface using a notched trowel. The height of the mixture should be about 0.5 cm;

- We put in place of fasteners and press. At the same time, we make slightly rotational movements. No air should remain in the solution;

- So we continue facing. To adjust the correct angle we use plastic crosses and for the correct seam we use plastic wedges;

Attention: After the solution dries, you need to go along the seam with the angle of a spatula and remove the solution. Otherwise, it will dry out and it will be difficult for you to evenly process the seam;

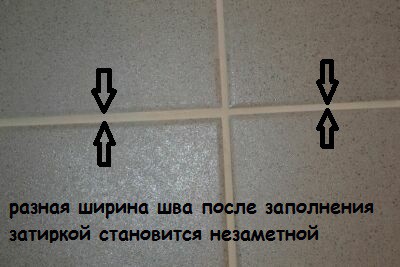

- If the tile is not even then you need to slightly increase the seam. In this version, the bumps are simply hidden by putty

- After the surface has completely dried, the seams must be repaired. To do this, dilute the putty.

So, as described above and after that we apply it to the seams. To do this, we use a rubber spatula and it is necessary to fill the seam completely. Just squeeze the solution into it; - We are waiting for it to dry. It will dry, not dry. The solution must be crude. We take rags and we wipe seams and a tile.

Caution: Do not wipe with a damp cloth. Water will simply wash the solution from the seam.

Wipe slightly damp. Of course, a white coating will remain on the plane. But it can be easily removed after drying with a dry cloth.

- After the surface has completely dried, the profile is removed and the lower row is fastened. We close the seams in the same way. Only you will need to cut the tiles and for this it is best to use a tile cutter.

Staggered mount

This is an easy and quick way to mount. It is used quite often.

It is especially good to use if you take cheap tile and it does not have the same size. Although its price is much lower.

So:

- Everything is done exactly as described above. Only here you do not use crosses, you should use wedges.

Attention: With such a fastening system, special attention should be paid to the correct placement of the tiles diagonally.

Customize it carefully. The outermost elements should be cut to one size. Otherwise, you break the entire configuration.

- Here you can successfully apply relief tiles, which will create the illusion of bulge.

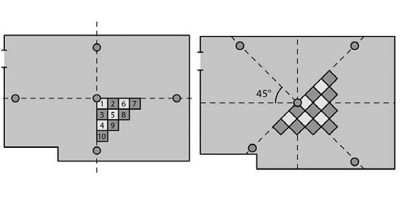

Fixing tiles diagonally

This option is the most complex and time-consuming, although it has several advantages:

- Such styling visually increases the area of the room;

- If the wall is positioned incorrectly along the perpendicular, it will hide this drawback;

- You can make a pretty organic drawing;

But this finish has its drawbacks:

- The tile must be of high quality. The slightest deviation is not allowed;

- A large amount of waste that is quite difficult to calculate in advance.

With this embodiment, you need to correctly mark the plane:

- First you should draw lines along the diagonal of the room. Tile fastening starts from the intersection of these lines;

Attention: Do not decide to put a seamless design in this option. This does not justify itself. You will have to do a lot of fit material. And this is difficult.

- It’s best not to make one quarter of the plane, but simultaneously move in four directions. Then you will visually see all the errors;

- We put the first row as follows.First, a straight rail should be applied along the line. After that, we apply the solution to the tile using a notched trowel and apply it.

Press and make slightly rotational movements. The rail will not allow the tile to shift from the line.

If you do not apply it, then the solution will simply hide the line and no displacement will be visible.

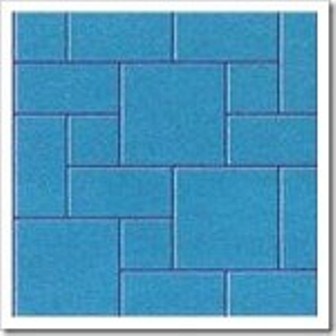

Making modular tile laying

This is a rather difficult way to do the job. It requires special attention. With this masonry, you can make very original drawings.

Let's see what are the features of this option:

- It is extremely important to choose a tile and it should be of the same texture;

- You can choose contrasting colors and make the picture very original;

Attention: In this option, three standard sizes of parts should be selected. Moreover, they must be multiple. Otherwise, you will fail.

- To do this, tiles that are labeled “modulare” are best suited. Here the edges are made with the highest quality and the size is correctly maintained

As you can see, everything can be done, just patience. The process of surface preparation and the correctness of marking are important here. Proceed and you will surely succeed.