Facing plasterboard walls: how to make

Modern repair work is not complete without surface leveling or the construction of multi-level ceiling structures. For this, one material is used, which has several types - drywall.

There is wall cladding with drywall without a frame or based on it.

The content of the article

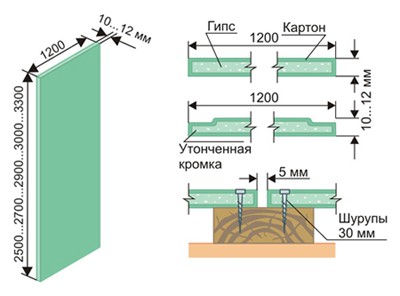

Characteristics of drywall and its types

Drywall is a material that consists of three layers. The first and third layers are pressed cardboard, and between them is gypsum dough - the second layer.

There are several types of such material:

- Arched, in which the sheets are perforated, which makes it possible to use them for the manufacture of arches (seeArch in the apartment: transformation into a decorative design) of any radius.

- Ceiling, which does not have a large thickness and is considered lightweight. It is used to align the ceiling or to build multi-level structures on it.

- Wall is intended for work on a wall surface. It is denser and has various sizes.

- In addition to the above types, there is also a moisture-proof and fire-resistant drywall.

- Drywall is popular due to the fact that the price is affordable.

There are two ways to mount the material:

- On the frame.

- Without him.

Tip. For decoration of rooms in which there is a very large number of electrical appliances and all wiring is hidden under the finish, it is best to use fireproof drywall, which will protect the room from fire.

Installation of drywall on the frame

This installation method is currently considered quite popular. It is very practical and after it there will not be much construction debris, unlike using plaster.

Note. Facing walls with drywall on the frame requires a number of preparatory work on the surface.

Surface preparation

All work of this type is easily done by hand. To do this, you do not need to have certain knowledge. The most important thing is to clean the surface.

It includes:

- Removing paint, as over time it can move away from the surface and fall under the finish.

- Chipping of the plaster, which has already moved away from the surface, to avoid a similar phenomenon.

- Getting rid of rust and mold if such fungal diseases are present.

- The next step is flushing the wall. It uses ordinary detergents that treat the surface, and they are washed off well with water.

Paint can be removed by washing, and plaster can be removed with a hammer and spatula.

Tip. To qualitatively finish the room, then all places where there are chips of plaster are covered with putty solution with a small size or with the plaster itself - if the defects are quite large.

- The surface after such work is treated with an antiseptic to protect the appearance of fungal diseases under the finish.

- Next, you need to make the layout of the room and determine the location of the main and auxiliary profiles. To do this, you need a tape measure and a pencil.

Tip. Proper layout of the room plays a big role, since the amount of material used depends on it.

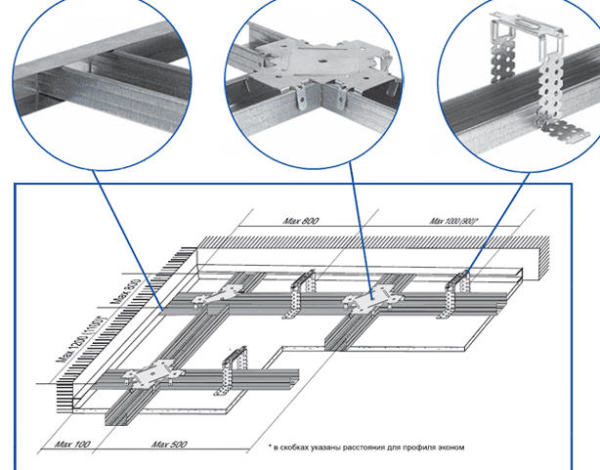

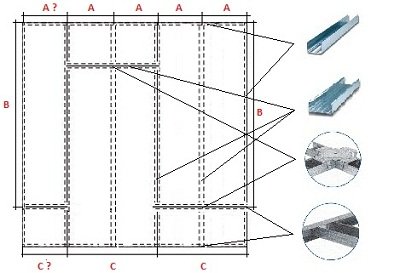

Mounting the frame on the wall surface

For such work, there is a certain instruction and special materials - profiles, which are used for the construction of the frame.

There are two types of them:

- Guides that are mounted in order to set the carcass and its further elements to an even position.

- Racks that serve as a support for the entire structure.

The frame is mounted directly on the surface.

To do this, use:

- Hacksaw or scissors for metal cutting profiles. You can use another tool - a grinder, which will make the cut very smooth and fast.

- Dowels with which profiles are mounted to the wall surface.

- Self-tapping screws that hold together all the frame elements together.

- A screwdriver and puncher, which can be replaced with a conventional drill for twisting fasteners.

- Construction level to ensure smooth installation of the frame on the surface.

- Tape measure and pencil.

Stages:

- The first to mount the main profile on the surface. Auxiliary are screwed to them.

- It should be noted that the cell size in order for the wall frame lining with gypsum plaster sheets to be of high quality should be at least 40-50 cm.

- This will allow you to securely fix the material and in the future to make a more durable finish.

The video shows an example of mounting a profile metal frame on a surface.

Installation of drywall sheets

Wall covering Drywall on the frame is quite quick and easy if the frame structure is assembled on the surface correctly.

For this, the following tools are used:

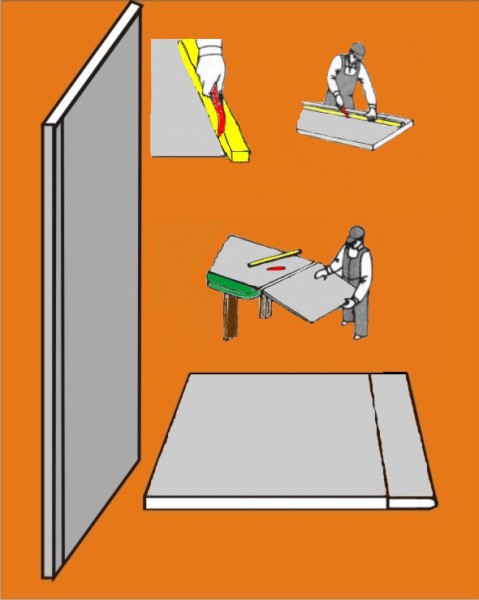

- Clerical knife, which is used for cutting material.

Tip. Instead, you can use a jigsaw, which will perform such work very quickly, but the quality of the cut will be much lower quality than when using an office knife.

- Construction level for even installation of each drywall sheet.

- Self-tapping screws with rubber caps that secure the sheets to the frame.

- Screwdriver for screwing them in.

Tip. Do not screw the screws too deep and tight, since the plaster dough from this can begin to deform. It is better to use a larger number of screws for reliable installation.

Each self-tapping screw from the other should be at a distance of no more than 30 cm.

Further processing of sheets after their installation:

- After the drywall sheets are completely mounted on the frame and in order to apply any finishing agent to them, you need to prepare their surface. To do this, all joints of the material are processed with putty, pre-glued with tape.

- It will be mandatory to mask all the screws so that they do not rust and do not spoil the appearance of the surface over time.

- Only now can plasterboard be lined. The photo shows examples of drywall lining.

What is the advantage of frame installation of drywall sheets

The main advantage will be that the alignment of the walls and the entire finish is quite quick and easy. In the process of attaching drywall, it is possible to warm the room and for this use various insulation materials in the seams or mats.

So:

- The most popular are polystyrene foam or polystyrene foam. Mineral wool is not used in rooms with high humidity, as over time it loses its properties due to moisture.

Tip. The thickness of the sheets of polystyrene foam or expanded polystyrene should correspond to the height from the surface of the frame itself.

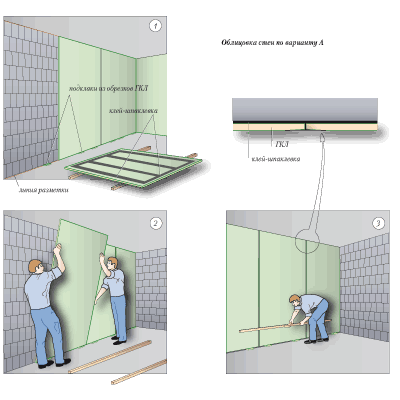

Frameless installation of drywall

Facing with plasterboard walls without a frame is a very simple way of decorating walls. It is performed on any surface. Only in this case should it be prepared.

The process of such work includes:

- Cleansing.

- Padding.

Note.It is imperative that the surface is smooth, since it will not be possible to qualitatively fix the sheet of drywall.

What is the advantage of such a finish:

- Frameless wall cladding with drywall has the main advantage - the speed of work. Also, it is not able to conceal the space in the room, since the installation is carried out directly to the surface.

- The disadvantage is that such a finish does not have the necessary strength so that decorative elements can be mounted on the surface of the material. It will not be possible to make a very large number of joints of sheets, since surface deformation may occur, and the corners of the material will not be in the same plane.

Tip. Installation work on drywall without a frame should be done with helpers, since the material has an impressive mass with a large size, and in order to avoid breakage one should keep it down and the second up.

The size of the drywall sheets can be selected according to the size of the room.

How to mount drywall on a wall surface without a frame

Frameless plasterboard wall cladding performed pretty fast. All the parameters of the room are preliminarily measured, and on their basis the cutting of the material is done.

For cutting materials use:

- Roulette.

- Pencil.

- Building level.

- The material is cut with the help of a clerical knife.

Tip. Cutting each sheet of drywall must be performed as needed. You will not need to cut each sheet at once, since in some rooms there is a different ceiling height and you can not guarantee an even cut. Quite often it is done diagonally.

Performance of work:

- If the surface has already been prepared, then the installation of sheets is carried out with a special glue or a tool that resembles adhesive tape, but will be more durable and durable.

- The product is applied to the surface of the drywall sheet on the side that will be mounted to the wall. Do not overlay its large layer, since deformations of even installation of the material on the surface (bevels, shifts in one direction or another) can occur.

Mandatory will use a rubber mallet, which tap all the edges of the sheet to more securely fix it to the surface.

As far as possible to issue such a cladding:

- The design of the plasterboard surface is currently performed by any modern finishing materials. Only here you need to carry out a number of preparatory work, as well as after installing drywall on the frame.

- The joints of the sheets are also processed with putty and the surface itself is primed.

- What is it for? Only after the surface is primed with high quality is it possible to more securely fix the finish on the surface of the material.

For work on wall cladding, it is better to give preference to moisture-resistant drywall.