Facing window slopes: application of the material

Facing window slopes helps not only to decorate the windows, but also to add a twist to the room. With the help of modern finishing materials, it is possible to create the original design of such an element of the structure.

The content of the article

Types of slopes

There are two types of slopes:

- Internal

- Outdoor.

By the appearance of such a part of the structure there are window and door slopes. By the method of decoration they are not too different. Most importantly, the material must be practical and durable.

Tip.

Finishing slopes of both door and window exteriors should only be carried out with moisture resistant materials. They are able to withstand the effects of weather and climate conditions.

What materials can be used for finishing slopes

What is facing the slopes of the window?

All work is performed using:

- Plastic clapboard.

- Sandwich panels

- Siding.

- Decorative stone.

- Paints.

These materials are suitable for both indoor and outdoor use. They have a large assortment.

Slope trim plastic

This material is currently the most popular. It is very practical and its price is quite affordable.

It has a wide range of species. There is a plastic lining or special panels. And that and that kind is mounted very quickly and simply and has an original design.

Plastic benefits

Facing door and window slopes plastic has a number of properties and technical characteristics that directly depend on the quality of the material itself.

Plastic:

- Practical and durable. It can be used for 20 years.

Tip.

In case of damage to any finishing element, it can be easily replaced, since plastic panels or lining cannot be repaired. Here it is worth paying special attention to the shade of the material, which may differ in another batch.

- Moisture-resistant, as it has a very dense structure, which under the influence of a humid environment does not have the property to change. Such a characteristic of the material makes it possible to use it not only in internal finishing work, but also in external.

- Wear-resistant, throughout the entire period of use of such a finishing material as plastic, its external design is not deformed.

- Fire-resistant, non-flammable and does not have the ability to melt or deform the structure from exposure to very high temperatures.

- Does not respond to low temperature conditions, like some finishing materials. It is able to withstand -45-50 degrees and not crack.

Facing window slopes with plastic does not tend to fade. This is due to a good protective layer of the material, which is applied to the surface during its production.

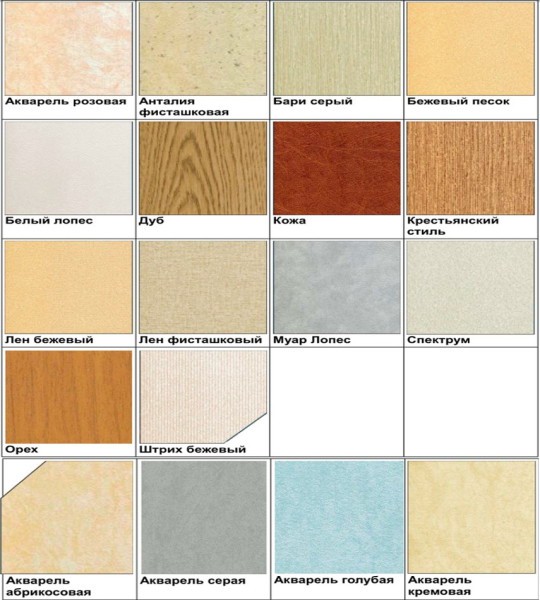

Varieties of plastic

At the moment there is plastic in the form of lining or panels. The size of the materials is different.

There are standard panels that have parameters of 1x2 m or 1.5x2 m. As for the lining, it can be 20-30-40-50 cm wide and 2.5-3 m long.

Choose the best option for slope finishes not be difficult.

Tip. It is best to opt for that plastic lining, which has the same size as the slope itself.This will provide an opportunity not only to save on the purchase of material, but also to reduce the time for finishing work.

Material Features:

- The surface of any type of plastic can be matte or glossy. Relief or structural surface is quite rare.

- Plastic is very easy to clean, but it is not recommended to do this with abrasive cleaners that can disrupt the structure of the protective surface layer, especially on plastic with gloss.

There is an imitation of masonry of natural or artificial stone. You can also choose brickwork.

It has become popular to depict ornaments or patterns on the surface of plastic lining. They are assembled with a single piece during installation and look very original.

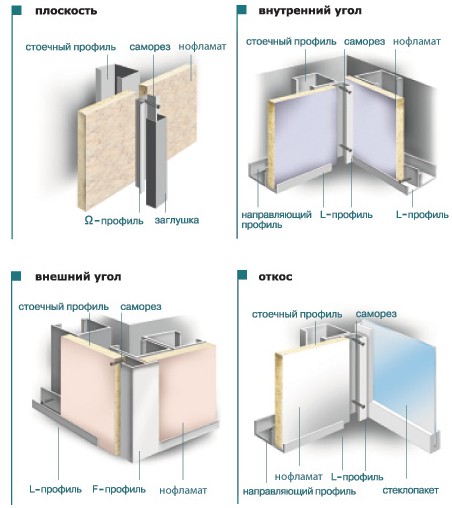

Installation of plastic panels or lining

Cladding plastic window slopes is quite fast. For such work, it will be necessary to make a wooden crate from the slats of small size on the surface of the slopes, so that the window space does not hide from this.

It is used in such a process:

- Dowels and screws.

- Drill and screwdriver.

- Eletrolobzik.

- Building level and tape measure with a pencil.

All work is done by hand, as there is nothing complicated in it.

To install the plastic you will need:

- The starting strip for such work is plastic.

- Construction level to give the finishing material a level position before fixing.

- Grinder for cutting material.

- Roulette.

- Construction stapler and screws if necessary.

Stages:

- The starting strip is immediately mounted and plastic strips are inserted into it. The first element of decoration is fixed with a stapler, since its brackets do not take up much space.

Tip. All joints of plastic are best treated with sealant.

- Also in the process of work, it is possible to carry out insulation. For this, thin sheets of foam or extruded polystyrene foam are used. They are inserted tightly into the cells of the crate.

All this is necessary for the reason that plastic is a very tight material and moisture can collect under the finish itself. So that the structure and the material itself from which it is built is not exposed to the effects of a humid environment, the isolation of slopes must be carried out necessarily, especially in a private house.

The video shows the installation process of plastic.

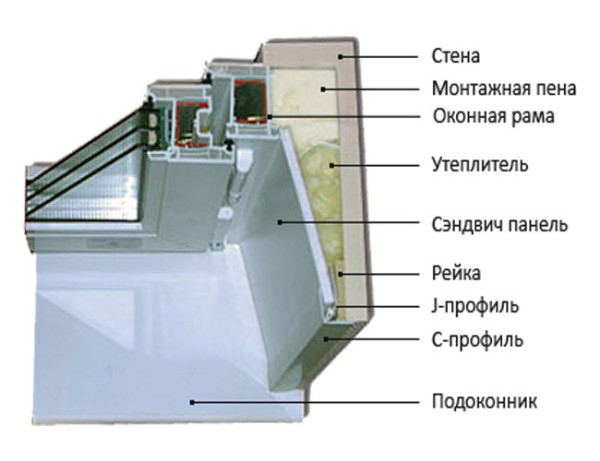

Slope sandwich panels

What is such material?

It consists of several layers:

- The first layer is the OSB sheets (back side).

- The second layer is insulating material (polystyrene).

- The third layer is the finish (siding or plastic).

Sandwich panels for facing window slopes began to be used relatively recently.

They have excellent characteristics:

- Moisture resistance and practicality.

- Durability and fire resistance.

- Frost and wear resistance.

Features:

- It is also worth considering that they have excellent heat capacity. They help to keep the heat indoors and thus prevent the slopes from deforming from exposure to a humid environment.

- Sandwich panels can perform not only slopes, but also the walls of the building. They have a wide range. The thickness of this material may be different.

Tip. When choosing it, it is worth considering that the minimum thickness of the sandwich panels is a size of 2 cm. For this reason, the slopes and the window itself must be at a certain distance from each other.

There is a surface of such material:

- Smooth or structural.

- Glossy or matte.

- Embossed or convex.

Installation of sandwich panels

As a rule, sandwich panels are mounted on special glue. But for slopes this way of fixing this material will not work.

For work are used:

- Self-tapping screws or nails.

- Screwdriver and hammer drill.

- Building level.

- Jigsaw.

For such work does not need instructions.The most important thing is to correctly and reliably fix the material on the surface of the slopes.

Tip. This choice of material should be given special attention, since facing the slopes with a sandwich panel is not only the original design of this building element, but also the insulation of the window opening.

Siding for facing window slopes

Cladding of window slopes with panels or siding strips is performed both from the inside of the room and from the outside. This material has the same properties as plastic, only in technical terms it will be a little stronger.

Features:

- It is also moisture-resistant and frost-resistant, as it is able to withstand not only temperature and climatic fluctuations, but also a low temperature regime, which in some regions reaches -50 degrees.

- Siding has a wide range of surface design. There are also, like on the surface of the plastic, various imitations and drawings.

- The installation of such material is carried out in a similar manner to that of plastic lining.

Tip. When performing such work, you can also make insulation and insulation of slopes using thin sheets of polystyrene foam or expanded polystyrene.

The use of plaster in the decoration of slopes

Facing window and door slopes using plaster is quite popular. To date, there are quite a variety of decorative tools of this type.

There is also plaster interspersed with threads or other elements.

Works:

- Layers of decorative plaster are applied only to the prepared surface.

- Initially, starting and finishing plaster is used for such work. The number of layers on the surface of the slope, that starting, that finishing layer depend on the number and size of defects.

After complete drying, each layer is treated with sandpaper:

- Very rough sandpaper (with large cells) is used for the starting plaster.

- For the finish - sandpaper with more small cells.

Tip. Facing a window slope will be of high quality only if the surface is primed with a special tool before applying the product.

To apply the plaster you will need:

- Two spatulas of different sizes.

- Capacity for mixing plaster mortar.

- Construction level to ensure a flat surface.

When using decorative plaster, sanding will not be necessary, since it can damage the surface of the finish. You can use more than one shade of such a finishing agent in your work.

The design in this case will be very original and unusual.