Sandwich Panel Slope Finishing: Team Leader Tips

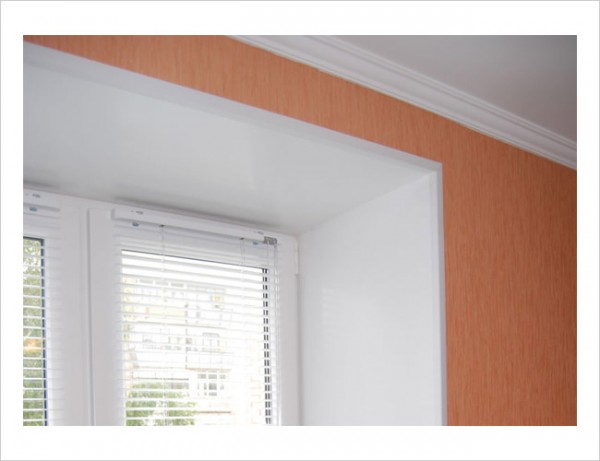

This article provides step-by-step instructions for finishing slopes. As the material used, we will consider a sandwich for decoration, which is optimal for this type of work.

Advantages of sandwiches over other types of materials:

- Moisture resistance and sufficient strength.

- Lightness of the material itself (about 1.6 kg. Per 1m2 with a sheet thickness of 10 mm.)

- Environmental friendliness and low price.

- Excellent noise and heat insulation.

- Easy installation (especially compared to plastering).

- Aesthetic appearance.

- Ease of maintenance and durability in use.

Useful! Begin finishing slopes should be no earlier than 1 day after installing the window blocks in the opening. Make sure the foam has dried before starting work.

The content of the article

Preparation for installation

Preparation process before trim slopes it is simple and includes 2 main stages: preparing the surface of the slopes, measuring and cutting the material.

For work, we need the following components and tools:

- PVC finishing strip (the so-called "P-profile") for 10mm panels.

- Plastic F-profile.

- Liquid plastic in a tube and a gun for it.

- Self-tapping screws with a preshaym (hemisphere) 3,5kh11mm with a drill.

- Screwdriver or screwdriver

- Tape measure and pencil.

- Hacksaw for metal.

- Retractable blade knife.

- Jigsaw.

Useful! Usually sandwich sheets have dimensions of 3000x1500x10mm. If you need to trim a small area of slopes, then do not buy a whole sheet.

Just pre-take measurements and when buying in the store, ask them to cut off the material. This service is available in almost all stores of building and decoration materials.

Slope surface preparation

Before you begin fastening the sandwich panel for interior decoration on the slopes, you must remove the excess foam that remains after the installation of window blocks. This can be done with a sharp knife with a retractable blade.

It is also worth removing poorly adhering and strongly sticking plaster or putty from the outer edges of the slopes.

Measurement and cutting of material

First of all, it is necessary to measure the internal perimeter window opening to prepare for fastening the finishing P-profile.

We do this in the following sequence:

- We measure the upper part parallel to the windowsill.

- We measure the side parts.

- We measure the width of the slopes in 4 places: in the upper part of the left and right; at the bottom left and right.

- Cut the finish bar into these sizes.

If you bought a whole sheet of sandwich, then you can cut it yourself with the help of a jigsaw or a hacksaw to metal.

Useful! The top of the sandwich should be slightly longer than the width of the window block. Minimum - 20mm.

It is better to measure and cut the F-profile after we insert the panels into the prepared edging from the finish strip.

Installation of slopes

Sandwich slope finishing consists of 4 stages:

- Installation of the finishing strips that you prepared in the previous step.

- Installation of sheet sandwich panels themselves.

- Edging of an aperture by F-profile.

- Sealing joints with liquid plastic.

Mounting the trim from the finish strip

Begin from the top of the opening. For fastening, we use self-tapping screws with a press washer and a screwdriver (screwdriver).

Fasteners are made to the edge of the window frame with a frequency of 100-150mm.

After the strap is fixed, you must immediately insert the prepared piece of the panel into the groove of the U-profile. The remaining sheets will be inserted after the complete installation of all the remaining pieces of the edging.

Now we attach the remaining parts of the edging to the edge of the window frame:

- First, we fix the side parts to the left and right. At the same time, they should be adjacent to the upper part of the slope and the windowsill as tightly as possible.

- Then we produce fasteners of those parts of the P-profile that we cut along the depth of the opening. The upper parts are attached directly to the upper sandwich.

Lower - to the windowsill (seeHow to finish the windowsill) In this case, it is better to check the accuracy of the fasteners of the upper and lower trims level or plumb.

This installation method will ensure that the slopes are fixed on three sides, and they will not hang. Self-tapping screws for fastening to the windowsill and the upper part of the slope is better to use without a drill!

Installation of sandwich panels in a fringing

Now insert the wall sandwich panels for interior decoration in the side trim. To increase thermal insulation, you can foam the space between the wall of the opening and the panel, if there is enough space.

At the same time, keep in mind that the foam will expand 1.2-1.5 times (depending on the brand). TYTAN PRO foam has a low expansion coefficient.

The outer edge should not be foamed, since we will still need to insert the F-profile there. If the gap between the wall of the opening from the outer edge and the sheet of the panel is too large (more than 10 mm), then you can make a strip from the rail by attaching it with a dowel with a screw.

Edging F-profile

To achieve a beautiful and aesthetic appearance of your window, you need to very seriously approach the measurement and the cut of the F-profile.

The parameters for the calculations are as follows:

- Side strips (left and right) are cut off by the height of the opening + one width of the edging profile itself. In this case, it is better to take a couple of millimeters more - the surplus can always be cut off.

- The upper bar should be a length along the width of the opening + two widths of the F-profile.

We cut off the edging and try on in place. After that, carefully trim at an angle of 45 degrees from the top of the profile.

If you get a small gap, then do not worry - it can be hidden in the next step.

Sealing joints with liquid plastic

Our slopes are ready and it remains only to seal up all the cracks and joints with liquid plastic. Take the tube with the gun and gently apply plastic to the joints at the corners of the slopes.

And also, if necessary, on the joints of the F-profile in the upper corners of the lining of the opening.

Useful! For this process, it is best to use liquid plastic. Silicone sealant has a “sticky” base and over time it may darken or turn yellow.

Hope that sandwich panel finish The slope was easy for you thanks to our article, and you got exactly the result that you expected.

A little tip at the end: you can shoot the installation process with explanations on the camera and upload the video to YouTube. This will help many people to make quality installation of slopes, and will give you popularity.

We would be grateful if in the description for your video you indicate a link to this article as the source.