Plastic window slopes - installation steps

The windows in the house serve as a source of natural light. In order for such an opening in the wall to look quite attractive, you need to carry out high-quality decoration of the slopes.

It is divided into: external and internal finishing work. Plastic trim of window slopes is very popular.

All this happens for the reason that plastic is a very practical and durable material.

The content of the article

Types of Plastic Panels

From the inside, slopes are very often done with plaster and plastic. You can use drywall for these purposes, which is then plastered and painted.

In order to finish the slopes from the outside use:

- Sandwich panels.

- Siding.

- Stucco.

- Brick.

- Plastic.

Plastic panels are a very interesting finishing material. It is used in decoration over a long period of time.

If earlier it was possible to meet panels of this type on the kitchen ceiling or in the bathroom, then today they are very well used in slopes.

Plastic panels can be wall and ceiling. Depending on this, there is suture plastic and seamless.

Such finishing material can be divided into several groups:

- Plastic lining.

- Plastic panels under the stove.

- Sheet panels.

Plastic wall paneling is designed for finishing work on walls or ceilings. It is attached using special locks.

Tile panels are often used on the ceiling. Such finishing material is available in the form of square tiles, which can have different sizes.

Sheet panels are an imitation of plywood sheet. A certain pattern is applied to their surface, which allows you to create a unique design.

They also have a difference in the installation process. As a rule, they are attached to the wall using liquid nails or glue.

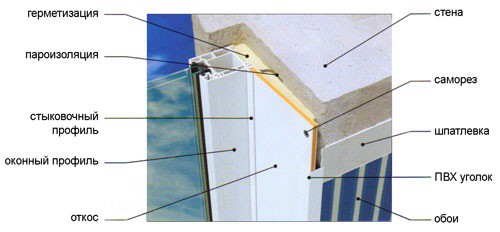

Tip. To ensure the tightness of the structure of plastic panels, all joints must be treated with sealant.

So:

- Plastic panels can be of different colors and shades. They are also found mirrored and matte, have a textured appearance and a laminated surface.

Widespread use today received a plastic panel under a brick. Very often they are used for finishing external slopes on a brick structure.

Accordingly, the price of this finishing material also changes from this. - Seamless panels should be joined joint to joint. Such joints on plastic will be slightly noticeable, but this does not spoil the appearance of the finish.

Especially it will be seen the connection of plastic panels during the installation of this finishing material with a smooth surface. - Suture plastic panels are a material that, when connected, can mimic a wooden lining. Its peculiar tub can be similar to a tub of parquet boards, since all the seams of such panels will be noticeable.

Very often, seam plastic panels are used when decorating slopes or other surfaces in wooden buildings, since their color can imitate the coloring of natural wood. Plastic panels are applied very widely.

Tip. When buying such a finishing material, you should pay special attention to the surface of the panels. It should be smooth and not have any defects.

The overall appearance of the entire structure will depend on this.

Very often sellers make mistakes when storing plastic. It may be held under any weight or lie in the wrong position.

As a result, the structure of such a material will be deformed, and as a result, after finishing work, roughnesses on the surface of the plastic or any defects will be noticeable.

The advantages of plastic panels

As window slope decoration plastic has become very popular, you can mention the advantages of such a finishing material.

So:

- Plastic panels have a long service life. They do not absorb moisture, which means they will not respond to seasonal weather events.

Also, plastic is quite resistant to climatic phenomena and is not able to deform under the influence of low temperatures. That is, we can say that plastic is frost-resistant. - Plastic panels are practically not afraid of mechanical loads, since this material has sufficient strength. The color of this finishing material is very diverse.

There is an imitation of stone or wood, which makes it possible to use the material in any design. - Before you install the panels you will not need to pre-align the surface of the walls. Plastic itself can without problems create smooth surfaces with its structure, which will help to a large extent save on finishing work.

- Plastic is an excellent soundproofing material. It can be combined with a heater (polystyrene foam or polyurethane foam) and then you can forget about temperature changes.

- Plastic panels do not burn, which means they are considered fireproof. All types of this finishing material are environmentally friendly and do not harm the environment.

They can be used in decoration, both on external surfaces and indoors.

Well, the main advantage of plastic panels will be that they are very easy to install and maintain. In order to clean their surface it will be enough to rinse them with water or simply wipe them with a damp rag.

For this, it will not be necessary to use special detergents, since the surface of this finishing material is not able to absorb various kinds of pollution. This makes plastic very practical.

Tools and materials required for the installation of plastic panels

In order to carry out the installation of plastic panels, it will be possible to use improvised material.

We will need:

- Plastic panels.

- Starting strip of plastic.

- External and internal plastic corners.

- Sealant.

- Drill or screwdriver.

- Level.

- Self-tapping screws.

- Construction stapler with staples.

- Wooden bars.

Shurovert is very often used to fix the starting strip of plastic to the surface of the slope. It will be rational to use if the wall is made of wood.

If the wall is made of brick, then it is more efficient to use a drill, which can greatly accelerate the installation process.

So:

- The level is necessary so that the plastic trim of the window slopes is better. Each panel is installed strictly according to the level, so as not to spoil the appearance of the slope.

- Auxiliary strips for mounting plastic are fixed with screws, and the first plastic panel can also be fixed to the wall with them. The stapler is very often used in order to fasten the panels together, which will give strength to the entire structure.

- Since the plastic panels in the installation are considered to be a universal finishing material, which can be mounted immediately on the surface of the wall or made for this previously crate. For this it will be necessary to use small wooden bars.

Tip. During installation, all plastic joints are best treated with sealant.This will give strength and additional density to the entire finish and will not allow moisture to penetrate the surface of the material.

The process of finishing window slopes with plastic

Finishing plastic window slopes is a fairly simple process. You can do it yourself and not spend a lot of time on it.

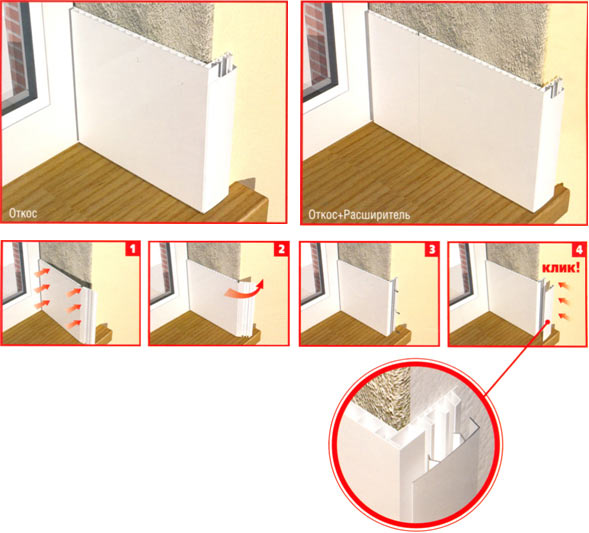

There is a certain instruction, observing that there will be no problems with the installation of such material:

Tip. The installation process must be carried out with the assessment of surface irregularities, so that you can decide on the use of the crate or you can fix the plastic directly to the slope wall.

- If the surface of the slope is not too smooth and has fairly pronounced defects, then it will be better to first build a crate. It will help not only to hide all irregularities with the help of plastic, but will also greatly help in its installation.

Also, plastic panels on the slopes will have a very smooth surface, which will create a neat appearance. - The lathing is made of thin wooden battens. They can be mounted on a slope at a short distance from each other.

If the window opening is not too high, then the wooden blocks can be fixed at the top, bottom and in the middle of the slope.

- The starting strip is mounted either on the wall or on such a crate. If it will be mounted directly on the wall surface, then in a brick building you need to use a drill.

In wooden houses, an ordinary screwdriver is used. The starting strip is attached at the top and bottom of the slope.

It performs not only the function of the guide, but also gives the strength of the structure. This will not allow the plastic to "walk" on the slope. - In order not to spend a lot of time, you can apply wide plastic panels. Sometimes, the width of such panels may correspond to the width of the slope.

This will greatly facilitate the installation of plastic and there is the opportunity to save on material. - If you give preference to less wide plastic panels, then you will need to type them very carefully. At the end of such finishing material there are special locks and the panels themselves are fastened together by a spike and groove system.

- The outer corners of the slopes are finished with special external plastic corners, which are fastened with liquid nails or mounting glue. In order for the slope directly around the window to be neat, you need to apply internal corners.

They are attached similarly to the outer corners. The photo shows an example of such a finish.

In order not to have questions about how to trim the window slopes with plastic, you will need to first obtain expert advice in this area. And it will be possible to see how plastic windows are trimmed, video slopes, which shows the whole process.