DIY door slopes

When changing doors in an apartment, a person inevitably faces the question: “How to finish door slopes?”. Even if the installation of doors is carried out by an invited specialist, he is not an assistant in this matter.

The master will only install the box according to the level, filling the seams with mounting foam, hang the door leaf, insert the accessories - and that’s all. What to do next, you will think for yourself.

We will talk about all the possible options for finishing slopes, and how to do it yourself. There are several types of materials that can be used for this purpose.

The content of the article

Drywall installation

Most often, they resort to this method of leveling the slope when the walls of the premises are also sheathed with drywall. Depending on the width of the slope and the degree of its unevenness, the finish can be done in two ways.

So:

- If the mounting seams are small and the slope is slightly damaged, the parts cut from the gypsum board can be glued with plaster glue. To do this, the surface on which gluing will be carried out must be well cleaned and covered with a primer layer.

- Naturally, you need to cut out the details of the slope as accurately as possible, given the angle of inclination. Installation begins with the installation of side panels.

Dilute the dry glue mixture with water as prescribed on the packaging. Apply the finished glue in a continuous layer to the slope part and press it against the prepared surface. - When the panels are installed, they must be fixed with masking tape and allowed to dry with glue. Then all the seams must be puttied, and then cleaned with sandpaper (null).

After applying another layer of soil, the slope is ready for subsequent finishing.

- Finishing the door slopes in the second way - this is the installation of drywall panels on a frame made of aluminum profile. It is more complex, and is used for frame cladding of the walls of the room, which significantly increases the depth of the slope.

- This is the prerogative of specialists working with drywall - few will be able to do this on their own, without certain skills.

To protect the corners of the slopes from accidental damage in the future, they are glued decorative plastic corners. This applies not only to plasterboard slopes, but also plaster and plastic.

Plaster slopes

Given that in most residential premises the walls are plastered, it is logical that the door slopes will be finished with your own hands in the same way. No special knowledge is required here, only some tools are needed, without which an even angle will not work.

Tools and materials

To mix the solution, in addition to the container, you will need a drill with a mixer tip. To ensure smooth slopes, you need: a two-meter building level and a rule.

Two spatulas are still needed: one with a width slightly larger than the slope, the other smaller. To primer surfaces, it is convenient to use a flat brush.

So:

- If you do not plan to use plastic corners during the subsequent finishing, it is possible to protect external slope angles in another way. For this purpose, a perforated metal corner is also used, which, before finishing the door slopes, is attached to the base surface of the slope with glue “liquid nails” or polyurethane foam.

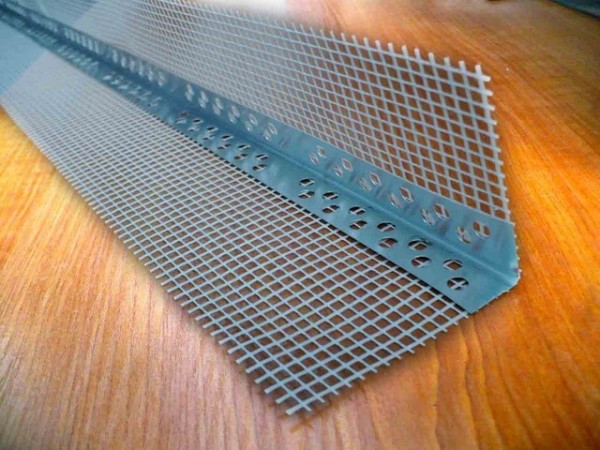

- To strengthen the plane of the slope, or the opening without a door, a fiberglass plaster mesh is used. And there is a variant of the corner combined with the grid into a single element - it is very convenient to use it.

- To prepare the solution, you will need to purchase dry gypsum plaster, diluted with water to the desired consistency. To save the solution, you may need foam.

- If there are deep potholes in the slope, or if its thickness exceeds two centimeters, the foam pieces are laid in the deepest places, and a layer of plaster is applied on top.

- In order not to spoil the door frame, its surface is pre-glued with masking tape. Only after this can you start priming and plastering the slope.

The last stage of the rough finish of the slope will be the processing of the plastered surface with fine sandpaper to achieve smoothness, and another layer of primer. To see how stucco decoration of door slopes is done - videos, which are many on the Internet, will help you a lot.

Plastic slopes

The easiest way to finish the slope is made of plastic. The price of this material is the lowest compared to the rest.

The only “but” - plastic slopes will not always look harmonious. The most appropriate is to trim the slopes of windows and doors with plastic, if a window, door, or wall covering is made from it.

The ideal option for such finishes are usually kitchens, loggias, bathrooms.

So:

- The most important thing when working with plastic is to achieve the most even and accurate cut. To do this, it is better to use an electric jigsaw rather than a knife.

Naturally, measurements must be performed accurately, then it is much easier to fit the parts to each other.

Plastic walls and slopes

- White sandwich panels are most often used for window slopes, and any PVC panel is suitable for decorating a doorway. If it is a balcony door, the finish of the slopes of which is made of colored plastic, then the slopes of the window next to it are decorated in the same way.

The picture above is a good example of such a finish. - If the doorway was badly damaged when dismantling the old door, then before finishing the door slopes with plastic, it is better to first remove the plaster slope with a margin of 1 cm. It will not be necessary to grind it under the plastic, and the mortar can be used not in gypsum, but in cement.

- If there is no significant damage to the opening, the potholes can simply be filled with foam. The same is done when MDF panels are used for decoration.

- To install the PVC panel, the start profile of plastic is fixed to the door frame with self-tapping screws. The side parts are installed first, and then the horizontal part.

Any universal adhesive intended for working with this material is applied to plastic. - The panel is inserted into the groove of the profile and pressed tightly to the surface. Then the glued part must be additionally fixed, until the glue completely dries.

You can do this with masking tape, or just back it up with something.

When the panels are mounted, the seams between them must be filled with sealant, and then closed with decorative corners. This completes the slopes on the balcony door.

Wooden slopes

Given that the interior doors are made of wood, it is logical that the slopes can be made of the same material. Such a doorway design in any interior will look harmonious.

So:

- To finish the slope, you can, of course, use panels made of solid wood, but veneered or laminated MDF is most often used. The usual laminate used for flooring is also suitable.

The main thing is that its color is ideally matched to the color of the door. - The technology of installing wooden panels is similar to plastic, only instead of the guide profile, there will be planks that are attached to the base surface with dowels. Further, the panels are screwed to the rails with self-tapping screws, not forgetting to put glue on the back side.

The joints between the panels are also sealed and closed with a corner.

- There is another option: buying doors, you can immediately buy and additional strips in color. Sometimes they come bundled.

They are made of chipboard coated with PVC film that mimics the texture of wood. - Extras can also be used if the width of the doorway is larger than the width of the box. Since these strips are attached directly to the box, dobors are mounted in the groove located on the back side even before the door is installed.

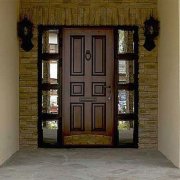

Sometimes door slopes are trimmed with decorative stone. This option is more suitable for entrance doors.

Indoors, such decoration is rare - mainly in design projects, but in the interiors of mansions. From the same stone, a floor or a fireplace can be laid out, appropriate accessories for room decor are used.

In this case, the slopes of decorative stone look original and to the place.