Aerated concrete bearing walls: do-it-yourself masonry

Calculation of the bearing wall of aerated concrete is based on the weight of the structure and the density of the material. Today we will tell you how the strength of aerated concrete for load-bearing walls is determined and what must be provided for proper masonry. Also on the video in this article and photo you can see the additional information you need.

The content of the article

The device of the bearing walls of structures of aerated concrete blocks

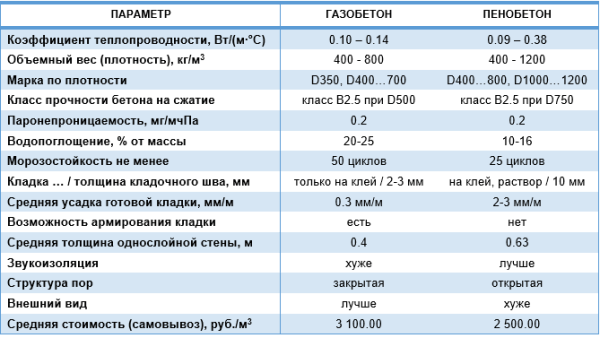

Aerated concrete and foam concrete (foam blocks) is a relatively new type of artificial stone material, which is a type of cellular concrete. Its masonry can be completely done with your own hands and this can significantly reduce construction costs.

So:

- Aerated concrete is a building material with uniform spherical, closed pores with a diameter of 1 to 3 millimeters.

- Immediately pay attention to the weight of the building. If it will be a room of more than two floors, then it is better to make load-bearing reinforced concrete walls. The density of aerated concrete for load-bearing walls is suitable for buildings of one or two floors.

- For laying walls, a foundation is made, the width of which should be 20 cm wider from the wall itself. The remaining space is taken from the calculation of the thickness of the lining layer.

The main positive characteristics of the foam block

This material has several advantages:

- From the foam block it is possible to build walls of any configuration at the same time, the architectural appearance of the building will not lose expression. All this provides a good appearance of the material and the ability to choose the required thickness of the blocks.

- The material has increased reliability;

- Environmentally friendly material;

- Good thermal conductivity walls made of aerated concrete blocks can significantly reduce heating costs.

- The material provides an optimum level of humidity in structure and creates an excellent microclimate;

- Good soundproofing and soundproofing;

- Economical consumption of finishing materials;

- Not a lot of weight material, facilitates the transferred load on the foundation;

- Increased Fire Resistance proven by many practical tests;

- Due to their light weight, foam blocks are easy to transport;

- Foam blocks are used for the construction of foundations, floors and load-bearing walls.

- Due to the porous structure, the walls of the foam block have the properties of high thermal insulation.

- Foam blocks work well, they are easy to saw, drill and adjust to the desired size

How to determine the optimal wall thickness of foam concrete

Regarding the optimal thickness of the walls of the foam block, there are many opinions, most of which are not entirely reliable information and almost not informative when building walls from the foam block.

In order to find the optimal wall thickness for a particular case, it is necessary to provide for the following:

- First of all, it is necessary to determine in which climatic zone the construction object is located, and to what minimum mark the temperature drops in the cold season.

- In areas with cold winters, wall thickness should be significantly thicker than in southern areas.

- Secondly, it is necessary decide on wall insulationwhether it is necessary or enough to do with plaster.

- It is also worth considering that this material is not facial and will need to be faced with something.So this width will affect the dimensions of the foundation.

- Also, when choosing products from a foam block, it is necessary to pay special attention to the density of the material, not only its price, but also quality characteristics depend on the density.

We look at regulatory requirements

Curtain walls made of foam concrete must meet certain technical parameters. This will be necessary when commissioning the facility. So when buying material, you need to pay attention to quality certificates and study the tedious parameters. The load-bearing walls in the house of aerated concrete must withstand the load.

Attention: There is an instruction, it is “Requirements of normative documentation”. The main recommendations of STO 501-52-01-2007 on the use of aerated concrete. So before buying it is worth viewing them.

The construction of load-bearing aerated concrete walls in the Soviet Union began around 1930, during which time many production technologies for the material itself were developed.

- All work on the manufacture of building materials, as well as the production of all construction works, including the construction of load-bearing walls and partitions and foam blocks, must be carried out in accordance with the requirements of regulatory documents.

- All construction work using cellular concrete (including aerated concrete and foam concrete) is regulated in accordance with STO 501-52-01-2007.

The main requirements and recommendations of normative documentation for cellular concrete used in the construction industry:

- According to the standards, it is necessary to determine the maximum wall height of aerated concrete only on the basis of a special calculation;

- The requirements of normative documentation limits the maximum permissible height of cellular concrete structures. For foam blocks it is 3 floors, while the height of the bearing walls should not exceed 10 meters.

- Also, according to normative documentation, the strength of concrete blocks in the first place should depend on the number of storeys. The higher the number of storeys, the stronger the material.

Normative documentation basically regulates only the strength characteristics of the material itself. Questions regarding the thermal insulation of buildings under construction must be addressed with the help of SNiP II-3-79. Compliance with the rules of regulatory documentation will facilitate the construction process from a legal point of view. After all, when drawing up documents for the finished construction, they are first of all checked with normative documentation.

So:

- In individual construction, the norms of technical documentation are mainly used as recommendations. Also, the fact that during operation the moisture content of aerated concrete blocks changes and the properties of heat conductivity increase, should be taken into account.

Attention: Applying the above, it follows that for a one-story building, the best wall thickness from aerated concrete for areas with a temperate climate is 300 millimeters, the density of the blocks is D600 and a thermal insulation layer is arranged.

- Foam blocks with such parameters are the best option for all regions of our country. Additional thermal insulation layers on the outside of the house provide winter without a feeling of cold.

- Regarding strength characteristics, even for a 2-storey building, the load transferred to the walls of the first floor does not exceed 20 tons, taking into account the weight of the roof and floors. It is worth noting that 300 millimeters is a fairly small strength indicator, for example, such a wall can be punched with a sledgehammer, but larger 400 mm foam blocks have greater density and strength.

The process of erecting load-bearing walls from aerated blocks

Masonry of bearing walls made of aerated concrete is done according to certain rules, they are time-tested.

So:

- Preparatory work. Preparatory work includes the preparation of the foundation. It is cleaned of dirt, dust and leveled.

- After, the need for the necessary materials is calculated, including the building blocks and glue themselves. For ease of calculation, there are about thirty blocks in one cube that have dimensions of 200x300x600 millimeters with a wall thickness of 30 centimeters.

- The amount of glue is calculated based on the linear dimensions of the walls and area. It is best to calculate the required amount of building materials at the preparatory stage or in the design process, in order to avoid unnecessary expenses during the construction process.

After preparing all the necessary building materials and equipment, you can proceed to the direct process of erecting load-bearing walls.

- Initially, you need to prepare an adhesive solution or buy a ready-made mixture. The adhesive mixture is distributed over the surface of the block, and then the blocks are laid out on top of the foundation or floor.

- The load-bearing capacity of the foam concrete walls will be sufficient if the dressing rules are followed. The seams in the order should not match. Otherwise, the wall will be weak and not reliable.

- Before laying the next block, the end face must be well lubricated with glue, in order to avoid the formation of gaps between the products. To eliminate excess glue, you can tap it with a mallet and remove excess with a spatula. The next row is laid with a shift of materials, to prevent the coincidence of vertical joints.

Attention: When building, immediately provide steps for the beams to overlap windows and doors. They significantly strengthen the design.

- Placement of openings for windows and doors. As noted earlier, cellular concrete is very easy to process, so placing openings for future windows and doors can be done without much difficulty.

At the final stage, warming and finishing of the facade of the house from aerated concrete or foam concrete blocks are carried out.

- If the building is planned to be finished in brick (see Facing the facade of a house with brick and stone: tiles and thermal panels), then between the blocks in the wall it is necessary to fix several reinforcing rods of not large thickness to connect the load-bearing wall to the cladding. Before this, it is necessary to install polystyrene boards.

- In the case of applying only layers of plaster, it is recommended to install a reinforcing mesh over the load-bearing wall. A thick layer of plaster is applied over the mesh for thermal insulation. Then a layer of any decorative plaster.

It is also necessary to remember several features of working with cellular concrete:

- The main criterion for choosing a material is density. So it is worth approaching her calculation very seriously.

- For laying and better adhesion of the blocks, it is necessary to use rationally selected adhesive solutions, it is best to purchase ready-made mixtures that are ready for use immediately after opening the package.

- It is also necessary to apply additional waterproofing materials, since the foam blocks are quite susceptible to moisture. The use of such materials provides a longer service life of the structure itself.

- For internal partitions, foam blocks of smaller thickness can be used. The best option is blocks with a thickness of 200 millimeters, in some cases, erecting partitions from blocks with a thickness of about 100 millimeters.

Do you make load-bearing walls of monolithic reinforced concrete or load-bearing walls of sawdust concrete, one important thing is the reliability of the structure. So pay attention not just to the load. And what kind of material can withstand.