Plywood wall decoration: simplicity, style or all together

The photo shows plywood, which is a lifebuoy in the manufacture of curved elements of the finishing processes. Plywood is plywood, so the price of this material is much lower than the cost of wood.

Plywood wall decoration is on a par with an effective way to obtain high-quality wall coverings. In addition, plywood sheet has a number of advantages, putting it on the same level with wood or slightly higher.

Plywood allows you to get a flat surface of the walls, hiding cracks, crumbling plaster and other various defects. Sheets can be covered with stain, varnish, paint, wallpaper, cloth, but can also be used as an independent finishing material.

The content of the article

Plywood as a finishing material

Plywood for interior decoration uses specific types, focused on the environmental performance of the material. It relates to a convenient, practical and economical way to finish reliable, wall and floor coverings.

Attractive appearance allows you to get interior design in traditional cozy and comfortable styles. The video demonstrates the combined use of various materials with the use of plywood, individual stains of wallpaper, the use of lighting and textiles.

Plywood Applications

Plywood is a concept familiar to everyone from childhood. Now plywood mailboxes have replaced their cardboard and plastic substitutes, but it is still widely used in industry, manufacturing and construction.

Plywood made of various wood veneers, with its color and pattern, coated with a transparent composition that preserves the structure of the tree, allows you to choose the right material for any simple or stylish interior.

So:

- Plywood FC, as a building material, is used for the construction of partitions, doors, the manufacture of window sills, wall panels. Used for roofing and floor finishes.

- The construction of scaffolding, various fences, the construction of shuttering systems, billboards and structures refers to the appearance of construction work using FSF plywood. Economical material for utility buildings for various applications and purposes, is widely used in the construction of sports and playgrounds.

- Plywood is used in the manufacture of furniture and serves as one of the basic components of most furniture enterprises. There is furniture made entirely of plywood - furniture for the garden, bathroom or kitchen.

Manufactured furniture is not complete without components from plywood. Shelves for cabinets, shelving, decoration of the furniture facade, the manufacture of drawers for cabinet furniture or a desk, the rear and side walls of the cabinet, bedside tables, chest of drawers.

For the production of furniture parts, FC plywood is used that does not contain phenolic resins.

Caution: The reliability of plywood, the strength of sheets and its resistance to stresses are ensured by gluing veneers, so that the fibers of one layer are perpendicular to the other.

- High-strength aircraft plywood is used in the construction of gliders or small-sized aircraft.

- Plywood FC, having the properties of increased moisture resistance, refers to an indispensable material for lining the deck and sides of a small vessel, and can also be used in the interior decoration of floating facilities.

- Plywood FC or FSF low grades used for the manufacture of containers and packaging. They transport fragile products, glass, crystal or products from them.

Plywood of higher grade is used in the manufacture of decorative packaging. - Transport engineering is not complete without these materials. A truck body, interior decoration of public transport inside - a bus, tram, trolleybus, railway carriage, the building of a mobile shopping pavilion, a trailer is a small list of the areas of application of plywood material.

The quality and advantage of plywood

What are its qualities and properties that have provided such widespread use and popularity in various fields:

- Ease of use is due to the release of square and large-format sheets. Created conditions for the selection of plywood, the corresponding size of the ceiling height.

It turns out a neat surface without patches and surcharges. - The flexibility of the material allows you to have smooth transitions between structural elements, to build unusual, different, curly structures in the room, for example, arches (seeArch in the apartment: transformation into a decorative design).

- The strength of the material and its thickness are used in the manufacture of general-purpose plywood, building material, furniture and decorative plywood, and bakelized and laminated plywood.

- The heat and sound insulation properties of materials are always used to create comfortable conditions in a closed room. Plywood sheets allow you to get a fairly dense environmentally friendly wall covering that can retain heat in the room.

- Needless to say, the cost-effectiveness of this material compared to wood.

- Light weight allows you to do your own work alone or with an assistant.

- Plates are easily cut, bent, drilled and amenable to processing.

- Finishing plywood on walls requires less labor and cost than using other, more expensive products.

Attention: The walls of attics, basements, garages can be sheathed with low-grade plywood 4-6 mm thick, which will allow you to get significant savings without compromising the quality of decoration.

- Finishing plywood to obtain a laminated surface consists in applying a film on both sides in a multi-span press at a temperature of 130-136 ° C. Conventional plywood sheets are used in a dry environment, and laminated plywood with high wear resistance and resistance to wet cleaning is selected for flooring.

- Finishing plywood and using a protective film allows you to protect the sheets not only from moisture, but also various chemical compounds that can corrode the coating. Laminated sheets of plywood are used for the manufacture of window sills, decorative panels, partitions.

It refers to universal finishing materials, which deserves priority attention when choosing materials for finishing work of various types of premises.

Plywood wall decoration sequence

The instruction contains specific recommendations on the size and thickness of the sheets to be selected, the preparation of the necessary tools and fasteners. The correct selection of products and the even surface of plywood sheets allows you to hide plaster defects, and eco-friendly material gives comfort, warmth and the ability to breathe the walls of the house.

So:

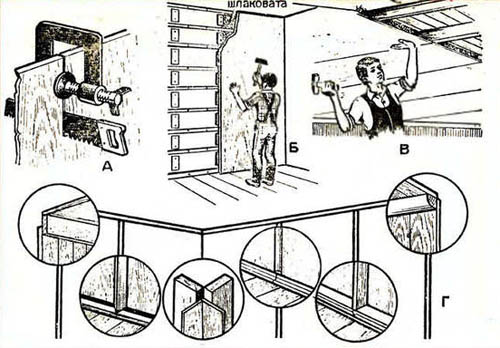

- It is necessary to pre-mark the prepared walls, determine and prepare the required number of battens for the crate. The thickness of the battens of the battens should be 1 cm thicker than the plate of the heat insulator, if wall insulation is planned.

- The installation of the rack frame begins. Mounting level, plumb, electric drill are used.

- Horizontal rails are fastened to the base of the surface with screws and dowels.

- At a distance of 40-50 cm from each other, installation of intermediate bars (racks) with fasteners through 50-70 cm is carried out.

Attention: It is necessary to achieve the maximum fit of the battens to the wall and before installation they are treated with a protective compound.

- To fix the edge of the plywood, vertical bars are fixed in the form of a “rail”. Cladding wooden walls is quite simple and the slats can be nailed directly to the wall surface with nails or cuts itself.

Metal suspensions are mounted on brick walls with a pitch of 40-50 cm with dowels, and then wooden slats are attached to the pendants. When installing the “rail” on brick walls, it is necessary to use a substrate under them from glassine or roofing material. - If necessary, the space of the crate is filled with heat and sound insulating materials.

- The sheets of plywood during the sheathing of the crate are joined end-to-end and very tightly. Some people use special sealants or putty to mask the seams.

Practice shows that over time the seams can diverge slightly and it is better to hide them with narrow wooden slats having a two-sided gutter. In addition, this can help protect the edges of the sheets from mechanical damage and from diverging seams.

Further work is carried out and depends on the wishes of the customer. Many go down the road to minimize finish wall decoration.

Others prefer the sticker of various figures made of the same material to give some volume to the structure or use the imitation effect for other materials. The flight of the host’s fantasies is not limited.

I always considered plywood to be not a reliable material both in strength and in dependence on external factors. I know that plywood reacts sharply to humidity and temperature. Until now, I considered that only plywood bodies and cargo cabins for workers of the north are finished with plywood, but no, it turns out that housing can also be finished. I think there will be plenty of fuss with plywood, first it needs to be sanded. It is good if there is a grinder, but if by hand several tens of squares of the surface of the walls? Perhaps such a finish is suitable for a summer residence, but it is unlikely for a city apartment, friends and guests most likely will not understand.