How is warming the walls with foam yourself

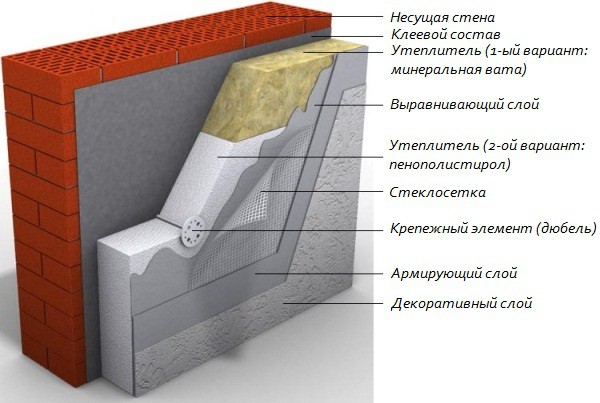

The insulation of the walls and facades of buildings with foam is performed to reduce the cost of heating the house in the winter, which is almost a third of them. There is nothing particularly complicated during the work, the main thing is to have an idea of what technology exists for foam wall insulation. About all stages of the production process will tell the article.

The content of the article

Features of foam for wall insulation

Features of the climate, which are characterized by cold off-season and harsh winters, make a person think about the quality of insulation of his home. For decades, an effective option is considered to be the external insulation of a brick wall with polystyrene. Attracts the use of the material of its characteristics, and most importantly affordable cost.

The benefits of polystyrene include:

- The thermal conductivity is quite low and ranges from 0.032–0.038 W / m * K. This is better than the classic mineral wool, and only slightly worse than extruded polystyrene.

- Excellent soundproofing.

- Manufacturers produce material in large volumes, it is constantly available in a large assortment and a good price category, which is almost half the price of extruded polystyrene foam.

- Relatively light weight. Depending on the grade and thickness, the weight of one square meter of sheet varies from 11 to 23 kilograms - these are the most popular grades: PSB – S – 15 ... PSB – S – 30. Significantly, the load on the building will not increase even after laying several layers of polystyrene foam, which increases the durability of the house.

- Simplicity and lightness when warming a building with your own hands: material is available in slabs with convenient dimensions. They are easy to cut, which allows you to adjust the shape of the existing building facade.

- The technology of foam wall insulation is very simplewithout the need for special knowledge and skills.

- The material does not rot.

- At not very high operating temperatures it does not emit harmful substances.

- Visually, the wall does not thicken too much.

The disadvantages of foam:

- Insulating walls with polystyrene is harmful to carry out indoors, this will significantly reduce the area of the room, and additional measures to protect the walls from the appearance of fungus will increase the cost of warming the building.

- The tendency of the material to absorb water prevents the insulation of parts of the building or pipes located in the ground.

- Polyfoam is subject to burning.

- Loose plates can attract rodents to arrange nests in them, which requires precautionary measures.

Tip: To protect the foam from rats and mice, a metal mesh with small cells should be applied to it, which should be considered when calculating the cost of insulation.

To facilitate the process of warming the walls with foam with your own hands, the video will tell you all the nuances of the work.

What materials are needed to work

Before you start insulating walls from foam blocks with foam, you need to purchase the right amount of material for work.

For this:

- The total area for decoration is determined:

- measured the height and length of each wall;

- the obtained values are multiplied;

- the area of windows and doors is subtracted from this result;

- add material allowance for slope manufacturing.

Tip: Styrofoam has a different density.It is not necessary to purchase the densest, it is enough to use sheets with an average density - PSB-S-25, whose thickness is ten centimeters.

- A special foam adhesive is purchased. Despite the relative high cost, it will guarantee to get the desired result - reliable insulation of the walls of the foam block with foam.

- For reinforcement after gluing the foam material, more glue is required, about the same amount.

- Need "umbrellas". They are special dowels for additional fixation of the insulation to the wall.

Their number is taken taking into account five pieces for each sheet of insulation, a length equal to two thicknesses of the foam used.

- A metal reinforcing mesh with cells of 5x5 centimeters is purchased.

- To make slopes and corners, painting corners are prepared (cm. Perforated plaster corner: how to use).

- It will take a primer.

Tip: If you are making foam wall insulation from foam block for the first time, you should purchase a little more materials than estimated, which will allow you to insure yourself against unnecessary waste.

How to prepare wall surfaces for insulation

The technology of warming the walls of a house with foam begins with the preparation of the insulated surface. When performing work on a new house, some moments will not be needed.

Surface preparation instruction:

- From the external walls, all unnecessary elements that interfere with the work are removed:

- drainpipes;

- ventilation grates;

- air conditioners;

- all kinds of wires;

- lamps with spotlights.

- If there are decorations on the old house that frame the eaves of the house and the window, they neatly get off.

- The plaster on the walls is tested for strength by tapping on its surface.

- Irregularities and deviations are checked with a plumb line, rule or cord of sufficient length.

- Discovered errors are marked with a chalk.

Tip: You can not take up insulation, in the presence of these shortcomings. First, you should remove the pieces of the falling plaster, then with a chisel, knock down the concrete flows and the mortar protruding between the bricks.

- After painting the walls with oil paint, it must be removed. Otherwise, the adhesion properties of the surface will be reduced.

- Mold, rust, greasy stains, and salt deposits must be removed.

- Cracks and irregularities with a height of more than 2 millimeters are primed with a deep penetration primer. The process is carried out by a special brush, which is called a mackerel, which will make everything faster and more accurate.

- After drying, the primer is applied. cement putty for outdoor use, all cracks are puttied.

- With very large irregularities of more than 15 millimeters:

- the surface is primed;

- lighthouses are placed;

- plaster composition is applied.

- Brick walls with a brush or roller are covered with a primer in one layer, of cellular concrete in two layers.

How to fix the start profile

Warming the walls of foam blocks with foam should begin with calculating the placement of the lower boundary of the walls to be finished.

For this:

- This level is measured at a hydraulic level at all corners of the house.

- A cord is stretched along these points, along which the bottom row of plates will fit, which will prevent the foam from shifting until the glue dries.

- The starting bar is selected by the length across the width of the heat insulator.

- The element is fastened with dowel-nails with a diameter of 6 millimeters, in increments of about 30 centimeters.

- At the corners of the house, the joints of the starting bar are made either with an oblique cut or with the help of an angular connecting element.

Tip: To avoid deformation of the structure due to temperature fluctuations, it is necessary to install plastic elements to connect them at the ends between the profiles located on the base. Overlapping profiles are not allowed.

- Fixation of the start profile is controlled by the level, as in the photo.

Ways of fastening a heater

Warming of aerated concrete walls with foam begins with the mixing of glue.

For this:

- Water is poured into a large plastic bucket.

- An adhesive mixture is slowly poured into it.

- To prevent lumps, a mixer nozzle is put on the drill, the tool is turned on at low speeds, the mixture is stirred until all lumps disappear.

- Five minutes, the composition settles for swelling.

- The electric drill turns on for 2 minutes and again everything mixes up.

- When the glue thickens, it just needs to be mixed again, without adding water to the composition.

Tip: To prevent thickening and drying of the glue, it must be used all in one and a half to two hours.

Next, the adhesive is applied to the foam boards.

This can be done in several ways, which depends on the evenness of the walls:

- With surface drops of up to 1.5 centimeters, the adhesive mixture is applied to the entire area of the foam plate, not reaching the edges by 2 centimeters. The thickness of the adhesive should also be 2 centimeters. In the center of the slab, with an area of 50 square centimeters, glue beacons with a diameter of 10 centimeters are evenly placed 7 times.

- For wall irregularities of less than one centimeter, glue strips up to 4 centimeters thick are applied along the perimeter of the plates and in their central part, which covers about 60% of the surface. After the insulation is pressed against the wall, the glue will occupy the entire space.

Tip: To prevent the occurrence of air jams, it is impossible to make adhesive strips continuous, they must be dotted.

- If the error on the walls is not more than five millimeters, with a special notched trowel, glue is applied to the entire base of the tiles.

When attaching the foam with umbrellas:

- It is necessary to fasten dowels with sheets of four elements at each corner, and one in the center.

- You can glue the entire foam, then strengthen it with umbrellas.

- This can be done immediately when gluing a particular sheet.

- When gluing umbrellas, you will need a hammer drill to drill holes.

Rules for mounting plates:

- The foam sheet is applied with a small, up to two centimeters, offset to the side from the place of gluing, and then put in place.

- The distance between the plates should be no more than two millimeters. With a larger gap, it must be repaired with construction foam, or with long, narrow pieces of polystyrene foam. At the same time, there should not be glue in the seams.

Tip: You can not move the plates until the glue hardens, they can stick poorly. To correct defects, the plate must be removed, the adhesive mixture removed from it, spread fresh glue and put the sheet in place.

- Installation of insulation is done from the bottom up, from the basement profile.

- When laying the material, the joints of the sheets should overlap, for this the foam is glued with offset.

Foam insulation between the walls is best done by blowing crumb from this material. How to perform wall insulation with foam balls with all the details shows the video in this article.

How to finish the walls

After laying the sheets, they are finished.

For this:

- Reinforcing mesh is laid. When applying glue to the polystyrene foam for the mesh, its layer is thicker than usual, which will allow the mesh to sink into the adhesive. After attaching the mesh, it is carefully smoothed.

- Strengthened corners. In this case, the corners are fixed directly to the glue and aligned with the rule.

- Wall plastering. This is one of the most complex and long processes when warming walls. In this case, one layer of plaster is usually not enough, it is more reliable to plaster the surface twice, the second the next day. This will be the final layer, which should be fairly even and neat, it will become the basis for high-quality painting of the walls.

If the material for building a house has a sufficiently large diffusion resistance to avoid condensation, it is necessary to perform wall insulation with foam with vapor barrier. This is usually done for the interior walls of the house.

High-quality insulation of the walls of any home will make the rooms in it more comfortable for living.