Facing of facades with granite and granite slabs

Facing with granite facades is not only particularly popular due to its characteristics and properties, but is also considered an eternal material. Millennial, granite buildings in good condition are still preserved, and granite cladding can stand for 500 years.

The price of the material depends on the thickness of the tile and on many other factors. Manufacturers from all over the world offer their products, in the photo you can see the geography - China, Ukraine, Ussuriysk, you can’t list all, and each customer has its own preferences and financial capabilities.

The content of the article

Special properties of granite

What properties and qualities made manufacturers stop on a material with natural strength:

- It turns out that such a solid mineral is not only polished to a shine, but also a mirror surface of the material is achieved.

- Granite has many colors and each of them is unique in its own way, and after polishing it acquires a special gamut and looks luxurious, rich.

- Simply magnificent drawings are created from a selection of different colors and combinations of textures of the same materials.

- If millennium-old granite buildings are preserved, it means that this material copes with temperature differences perfectly, it is not afraid of frosts, high temperatures and their dynamics.

- It has the ability to retain heat and belongs to good soundproof materials.

- Granite stone does not need frequent care, it is easy to clean from dust and traces of atmospheric residues.

- Granite in facade cladding allows for decades to forget about the problems of external walls and their repairs.

Attention: The durability of products and their cost are decisive when choosing a finish color, because the desire to change the color of the facade will lead to costly repairs.

- Black granite, rich and vibrant colors of red hues are expensive products.

- Gray granite is cheaper than the rest, but it has less strength.

- You can choose black or red granite with all the qualities inherent in this material, but at a lower price, if you save on gloss, or rather its absence. The surface of granite is simply not brought to a matte shade.

- Finishing quality is determined by several factors. Strong, even surface of granite, fastening is carried out with special solutions or fasteners, work is done not with your own hands, but by highly qualified specialists.

Various technologies for fixing facade granite

Facing of facades with natural granite is carried out according to various technologies:

- The traditional method includes the method of attaching plates to special adhesive solutions.

- Granite for cladding is produced. ventilated facadeIt has a smaller thickness. The mount differs from the classic look, and granite is available with a special ceramic finish.

The complex of works with granite tiles allows you to save money, and it is impossible to visually determine the difference.

Obtaining a monumental surface

Facing with granite facade allows you to get the most durable building with a monumental surface in the "wet way":

- Preliminary surface preparation. Granite material requires a solid base, so old plaster or gypsum is completely removed.

It is not necessary to remind that the stucco left can crumble over time, this will require repair, and the conversation is about a monolithic surface. - The permissible deviation of a flat space per square meter may be no more than 2 mm. What is this size talking about?

- The surface should be without cracks, protrusions, pits, that is, carefully leveled. Otherwise, facing a large surface will give differences to the edges of the plates, which will cause a logical decision - to regulate blemishes with a solution.

Here you can get stuck in a dead end, the technology manual often does not allow the use of a large layer of the mixture. - What if there is a need to plaster the walls?

- You can’t rush to use granite for cladding building facades, you should take the time necessary to completely dry the plaster.

- Then notches are applied after 5 cm, if the surface is smooth, if rough, then there is no need for notches.

Attention: Several lighthouse plates, laid on both sides of the wall from below and above, set the even direction of the masonry. Each plate is checked horizontally and vertically, it must be placed perfectly evenly so as not to spoil the entire lining.

- Granite for facade cladding have sufficient weight. Their installation should begin from the bottom and lead up.

- Rare cases of masonry, on the contrary, have good reasons, one of them is the prohibition of the ingress of mortar from the upper plates to the lower products.

- To support the first row, a wooden support is placed below. After setting the first row, the second fits.

- Each plate and row as a whole is checked by plumb and level.

- The cord stretch, which serves as a guideline for the upper part of the plates, allows you to evenly lay rows.

- After performing a certain section of the masonry, when the facade is faced with granite, it is necessary to grout the joints, but not earlier than in a day. The nuance is that the seams can not be kept open for a long time.

- Grouting of joints is carried out with special compounds based on epoxy resin.

- It is not only a reliable grout, but also does not allow moisture to pass; the facade cladding of the building is made of granite with a particularly strong surface made by the traditional method.

Granite tile mechanical fastening

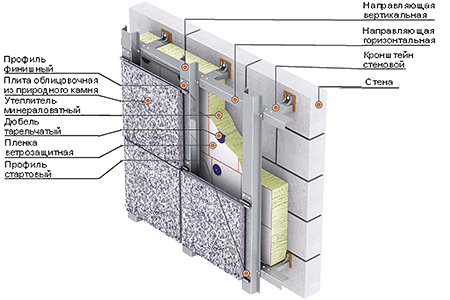

If the facades of houses are faced with granite in the classical way and does not require additional insulation, then there are many examples where the building needs additional insulation and ventilated facades. Technology facades granite and marble grew into a network of workshops, where they trained class masters of their craft.

Watching the video of the masters, you understand that granite became not only a stone of palaces and temples, it came out of the shadow of the palace porticoes and moved to our streets.

Polished slabs adorn the facades of wealthy city dwellers and considerable money is spent to decorate the facade:

- Facing facades with granite tiles begins with the marking of the surface.

- Brackets are prepared for installation work.

- Brackets are mounted and tamped with dowels.

- Anchors are wrapped.

- Brackets are mounted.

- Installation and fastening of the insulation is in progress.

- Facade cladding granite tiles continues with mounting rails.

- The plane is set and the guides of the plane are fixed.

- Aside, the corner element is being assembled for fixing granite tiles.

- When working, a minimum of tools is used - a drill, screwdriver, level.

- The finished corner element is attached to the junction of two walls, leveling is carried out, marking is applied for the end clamp.

- Granite tiles for facade cladding are mounted and an external facade screen is created.

- Ordinary clamps are installed, in general, the process of constructing a sub-structure can be compressed into four words - drilling, fixing, installing tiles, leveling.

- The installation of a ventilated facade transforms the structure, insulates it; indisputable advantages include a wide selection of color combinations.

- Possibility of using various facing materials, high sound insulation.

- Savings on the installation of heating systems in rooms.

- Long life and operation.

- Resistance to the dynamics of atmospheric changes.

- Possibilities of operational installation in any weather conditions and in any season.

The ventilated facade performs a protective and aesthetic function, decorates the appearance of the building. Natural stone, to which granite can be attributed, has a special effect.

A hinged, ventilated facade cannot be used in the restoration of historic buildings in order to preserve the original appearance on buildings that have elements of architectural decor in the form of cornices, columns and other products.