Facing the facade with granite: the nuances of work

Porcelain tile for facade cladding was imported into the country until the beginning of 2000 from Spain, Italy, Belarus and other countries to cover the growing needs of the Russian market. A new technological material led a group of domestic entrepreneurs to think about building their own, the first factory producing porcelain tiles for facing facades using Italian technology.

Fortunately, there is plenty of raw materials and no need to go far; the suburbs were chosen as the place for construction.

The content of the article

How not to make a mistake in choosing tiles

In the photo and video it is clearly visible that porcelain tiles are produced in tiles of different formats. An assortment of one manufacturer contains several sizes, for example, 300x300 mm, 400x400 mm, 600x600 mm.

There is no point in releasing less, because a correctly selected format is very important for work:

- Working with small tiles seems to be easier because of the weight.

- The larger the size of the porcelain tile, the fewer joints per square meter, and they require grouting to make the seams inconspicuous or completely masked as a monolith.

- Again, porcelain stoneware in facade cladding large format 600x600 mm requires careful preparation of the surface, and small tiles are laid on a less even base.

- The ends of the tiles, after pressing and firing in the furnaces, remain uneven, but the size of these protrusions can vary greatly in caliber, sometimes 1-2 cm.

- Packaging of products is made from one batch, that is, of the same caliber. Instructions for use, the size of the caliber is indicated by letters or numbers and is presented on the package. Carefully select products when buying.

- The price of a mono-caliber, as it is called rectified porcelain tile, which is produced in a single caliber, for which an additional processing stage is performed in the form of trimming the edges, much higher than usual.

- Since the products are very hard, edge trimming is performed on special equipment using diamond tools.

- Despite the high cost of rectified porcelain stoneware, it is used much more often in systems known as ventilated facades.

Attention: The monocaliber allows to carry out facing of a floor and walls without seams.

- The strength of porcelain stoneware is determined by its thickness, which increases its value. Why do consumers find cost increases justified?

Probably because such products will be used floor finishes under increased loads. - Often the increase in thickness is accompanied by a small format, such a product is called "technical porcelain stoneware" and is used in industrial premises and warehouse complexes.

- When deciding to apply facade cladding, it should be understood that the characteristics of the material are similar to natural stone. High density makes it heavy, imparts excellent performance, but limits application.

- Finding the same shades of porcelain stoneware is a buyer's task. The technology consists in grinding and mixing clay, sand, feldspar, other natural materials and dyes, but an ideally uniform consistency is not obtained.

In the packaging of finished products, they try to choose one shade and tone, its indicators, like caliber, are also present on the package.

Attention: It is better to purchase porcelain stoneware “in reserve” than then to sort through other batches with one tile in search of the desired shade.

Types and properties of porcelain stoneware

If we single out the main properties of porcelain stoneware, we get a short list that carries the huge potential of this material:

- The minimum rate of water absorption, almost equal to zero.

- Ceramic granite is used for facade cladding due to its high frost resistance.

- Wear-resistant, durable material. What do facades most often suffer from? Mechanical damage, dents, scratches, and porcelain stoneware is a durable product that can last quite a long time.

- Resistance to UF-radiation and temperature changes, which is relevant for our country, where there is a sharply continental climate.

- Cladding house facades porcelain stoneware is surprisingly durable and is able to last a century or more without visible changes, which indicates its resistance to organic solvents, acids and alkalis.

- Unglazed porcelain stoneware in terms of hardness exceeds the best varieties of natural granites, does not have a decorative layer, is painted over to the full depth and has a uniform structure similar to natural stones.

- Glazed material can be attributed to the intermediate link between single fired ceramic tiles and porcelain stoneware. Family ties can be traced in the increased hardness and strength of porcelain stoneware and in the decorativeness of ceramic tiles.

Attention: Glazed material is not used in public buildings with intensive use, due to the erasing of the glaze from time to time.

- Facing with porcelain tiles the facades of houses is not only practical, but also carries an aesthetic function. An ultra-modern, presentable design of the facades is ensured by applying different colors, combining different sizes and using different textures of the products.

Why Ventilated Facades

Indeed, why bother with a garden if you can just stick tiles, combining them in color and size?

The use of facade solutions affects the life of the building, the frequency of maintenance and the cost of maintaining the property. Ventilated technologies demonstrate the rich plasticity of facades, the use of materials of various colors, shades and textures. Facing the building facades with granite means the use of industrial products, which is a guarantee of compliance with established standards and safety requirements.

So:

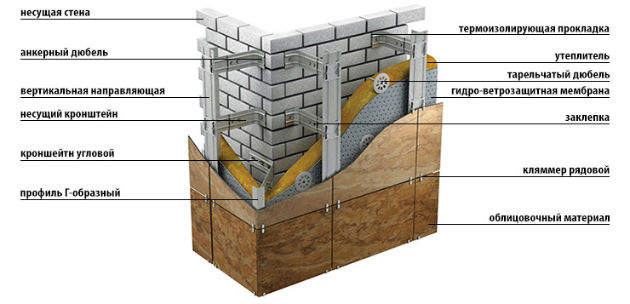

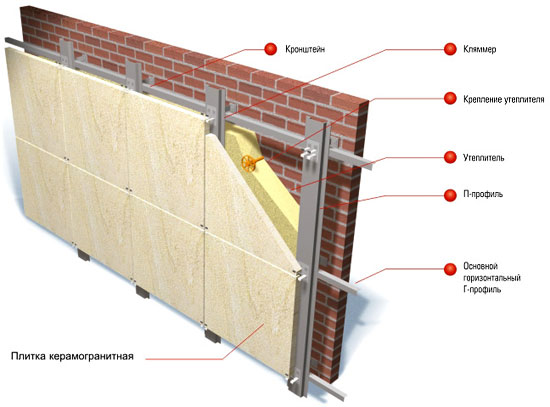

- What functions are ventilated facades? The diagram above shows that this is a structure consisting of products of the cladding itself and a substructure of the cladding.

The substructure is made so that between the wall and the protective and decorative cladding there is a ventilation gap from the air gap. - The facade system is not a tribute to fashion and prestige; their development and implementation is based on economic calculation based on long-term observations and statistical data.

- The facade of buildings is exposed to atmospheric conditions all year round, which reduces their service life, destroying their surfaces.

- The hinged ventilated facade is one of the representatives of modern and popular technology for the external design of the facade and cladding of buildings.

- It is an aluminum structure of various types and complexity, fixed on load-bearing or main walls, on which ceramic granite tiles are mounted for facing facades.

- Between the cladding and the wall, thermal insulation is placed so that there remains a layer of air that freely communicates with the external atmosphere.

Open type ventilated facade

So:

- The name and definition of the type of facades were obtained by the use of fasteners for mechanical fixation, which are divided into open and closed types.

- Fastening to the supporting profiles of the facing material with clamps, rivets, self-cuts - open type.

- They are subject to the basic requirements for reliable fastening of porcelain stoneware to structures, ease of installation, lack of vibration, color matching of fastenings with lining.

- The advantages are structural reliability and cost-effectiveness.

Attention: The open method is acceptable for tiles of small and medium sizes, because the closed type is quite expensive.

Closed type

Cladding the facade of the house with porcelain stoneware requires additional processing of panels and increases the cost of construction.

So:

- This type is used for buildings located in the zone of increased vibration loads. These include railways, existing underground lines, underground and other structures.

- The structure is fastened with fixing screws, which prevent lateral displacements of the facing plates during vibration.

- Cladding plates are attached to the system with collet-type anchors, which are inserted into blind holes provided on the back of the plate.

- The advantages of the closed type include strength and aesthetics of appearance.

- Strength is achieved by placing the system on a grid of thin steel, which does not even allow a piece of such a cladding to break off.

- Fastening systems are successfully combined when a closed type is placed at the lower level, and the top is formed in an open way.

Briefly about the functions of ventilated structures:

- Facing the facade of the building with granite performs a protective function. The design of the supporting profile provides a system for removing moisture from the facade surface into the drainage, which excludes contact with the insulation and the building wall.

- Thermal insulation is achieved by the joint use of a special profile system for these facades and heat insulators that provide natural ventilation of facades. This design does not require the installation of expensive air conditioning systems, it itself serves as a sun screen, which allows you to create a comfortable microclimate in the room.

- The ventilated design turns the house into a kind of thermos that retains heat thanks to a layer of heat insulator under the cladding. You work in an office where in winter, instead of three batteries, only one works, and is it hot?

Insulation allows you to reduce energy costs for heating, reduce the thickness of the bearing walls, thereby reducing the load on the foundation. Such houses give heat 5-6 times slower during emergency blackouts in winter. - A specially developed installation and wall mount scheme allows you to absorb thermal deformation that occurs during daily temperature drops, complicated by seasonal changes.

- The hinged system increases sound insulating indicators by 1.5-2 times on average, which, complete with vacuum double-glazed windows, provides silence in rooms located even in noisy places.

- Facing the facade with granite tiles complies with fire safety standards due to the inclusion in the system of materials belonging to the class of difficult to combustible or non-combustible and preventing the spread of fire.

- A long service life is ensured by observing the installation rules, accurate calculations of the installation of the substructure and combinations of laying insulation and cladding.

- Examples of facade cladding with porcelain stoneware - a wide selection of products and the practical possibilities of unlimited combinations, a respectable look and space for design solutions, any project can be given uniqueness from the aesthetic side.

- Replacing obsolete technologies that use paints and plasters, whose life is limited.

- Resistance to external manifestations, including the efforts of active teenagers who are disposed to destruction and express themselves in increased aggression.

- Facade repair can be performed without dismantling the entire structure and damaging the external walls; it is possible to change individual parts or blocks.

- This allows you to fundamentally change the architectural appearance of the entire facade, combining facing materials, choosing different formats and using color inserts.

Facade Tour

So:

- Facade cladding with ceramic granite directly to the surface with a mortar of building glue is called “wet”.

- An important point here is the correct selection of glue. Requirements are made for him to hold a rather heavy, facing material, and in addition he must withstand the effects and changes of the environment for a long time.

- Walls are carefully prepared under the “wet” finish. They are cleaned of impurities, defects are eliminated, leveled and primed.

- Facing with porcelain stoneware facades on the substructure allows for installation in any off-season, lower requirements are imposed on the surface of the facade. The cost of work is higher than the previous method and it is undesirable to do it yourself.

- The work is divided and carried out in several stages. Initially, the base is installed under the slabs.

- The facade cladding of porcelain stoneware lies on the insulation layer, because the plates themselves are not able to retain the heat of buildings, so this stage of work is necessary, and you can not do without it.

- Wind barriers are mounted on top of the insulation to help protect buildings from heat loss and increase the reliability of the entire structure.

- The latter is faced with porcelain stoneware of the facade, it is fastened with bolts disguised with plugs.

We can state the fact that the ventilated facade consists of a multilayer structure on the frame, including the facing material, a layer of thermal insulation and wind protection. Different regions of the country, with different climatic conditions, even buildings in the south, can not do without a thin layer of insulation, let alone the northern regions, where you can not do with a thin layer of insulation.

Modern porcelain tiles are literally irreplaceable material for finishing works, an example is country houses, the owners of which prefer a long service life in combination with aesthetic refinements.