Facing the facade of a house with ceramic tiles: what you need to know

Ceramic cladding of facades refers to those types of coatings that have an almost unlimited service life. No less important is the aesthetic aspect: with a combination of different colors and textures of the tiles, excellent design options are obtained.

Facing with ceramic tiles of facades is carried out both in glue and in frame way, which makes it possible to choose the most suitable technology not only for concrete and brick, but also for wooden walls. The instruction and video in our article are to help those who decide to make their own finish.

The content of the article

Facade tile

About great features ceramic tiles it is unnecessary to speak, because there is probably no such house or apartment where this material would not be used. Everyone knows about its main advantage: waterproof.

Due to this quality, the tile is also suitable for outdoor work:

- Ceramic cladding of the facade to the maximum protects the structure from weathering. Moreover, it serves as much as the building costs, unless, of course, there were no violations in the production technology.

The owner of a house faced with ceramics will never have to solve the issue of updating the exterior walls - it is enough to wash them from time to time. - Facade tiles differ from the options used in the interiors, thickness, formats and design. Small-format tiles are mounted on glue, and most often, they have the configuration of the spoon side of the brick. Large-format ceramic tiles for facade cladding are installed on the frame, which makes it possible to insulate the walls during the finishing process, as well as hide their unevenness.

- The design of coatings for exterior walls, most often imitates various types of brick and stone. Such decoration on the facade looks most harmonious, but, if desired, the outer wall can be decorated with colored panels.

The main thing is that such a decoration should be in place, and not cause dissonance in the appearance of the building.

- If you compare the facade tiles with full-face front bricks, its advantages in decoration are obvious. Having the same aesthetic effect, the cladding weighs little, and therefore does not require additional support on the foundation.

All ceramic tiles for facade cladding are produced in accordance with GOST 13996-93, which regulates its properties necessary to withstand multiple cycles of freezing and thawing.

What ceramic cladding materials facades fit best?

To understand this issue, and make the right choice, our small review will help you:

| Kind of tile | short information | Size range |

| This type of tile is made from kaolin clay. Before getting into the raw material mass, it should remain in the open air for almost a year after extraction.

Terracotta tiles are extruded. That is, the raw material mass is pressed through the extruder, and then the layer is cut into billets.

| Ceramic facing tile for the terracotta facade, is produced not only in small format 240 * 71 * 11 mm or 302 * 148 * 12 mm, designed for adhesive installation.

The maximum width of such a panel can be 60 cm, and the length can reach 1.8 m - this is exactly what you see in the above photo.

|

The peculiarity of clinker tiles is that in its production only shale clay with a certain chemical composition is used. It should not be impurities of lime and salts.

The natural color of these products varies within the yellow-brown range, and with the help of dyes, you can get any shade.

| Here are some sizes of clinker tiles. 210 * 52 * 11238 * 64 * 18240 * 71 * 14 250*65*10 302*148*12 Larger formats and thickness, as a rule, has a tile that imitates stone. | |

Tiles with such an interesting name gained popularity at the end of the IXX century, in the era of the dominance of the modern architectural style. Many buildings built in those days have just such a cladding, and mind you, it still does not require replacement!

It is enough to hit the butt with a hammer, and the disc splits into two halves, turning into two tiles. If you take into account that its edges are beveled, you get a now fashionable volumetric relief. By the way, manufacturers of clinker tiles often offer consumers products that mimic the surface of the “boar”.

| Standard dimensions of the “boar” tile: 285 * 85 * 9 mm250 * 100 * 8 mm120 * 60 * 8 mm | |

| Porcelain tile is somewhat different in composition from ceramic tiles. In its production, in addition to white clay, sand is also used. But, in the process of pressing and firing, the products are more dense, and, accordingly, durable, have almost zero water absorption. | The size range of porcelain stoneware is very large, but for the decoration of facades, the following sizes are most often used: -for glue installation 30 * 30 cm and 45 * 45 cm-for assembly of ventilation facades: 30 * 60; 60 * 60; 30 * 120 and 120 * 180 cm. The thickness of the tile usually does not exceed 14 mm. |

- Facade cladding ceramic tiles, is one of those types of finishes that give almost unlimited possibilities for design. It is equally used in both low-rise and high-rise construction. The higher the building, the more severe wind loads are exposed to its walls.

Therefore, in the process of designing buildings and structures, their cladding is calculated in the same way as supporting structures. Accordingly, the material for the exterior is selected according to these calculations.

Facing ceramic facade tile is one of the few materials that can withstand almost any load.

Facade cladding technology

As we have already said, there are two ways to mount ceramic tiles on the wall: on glue, and, on a system of ventilated facades, on the crate. Theoretically, the tile can be glued to any surface, even wooden and metal, but preparing the surface, in this case, would be quite time-consuming.

What's the point of this:

- Moreover, today, manufacturers are offering facade systems, such as Ronson, which provide for the installation of even small-format tiles on a frame.After all, it is she who so attracts homeowners with her beauty, and similarity to brickwork.

- For this reason, the adhesive cladding of the facade with ceramic tiles is good only for concrete or brick houses with small floors. Let us briefly consider the technology of its implementation.

Mounting tiles on glue

In order for the lined wall to look beautiful, it must first of all be flat. And it is the condition of the walls that sometimes plays a decisive role in choosing the method of mounting the tiles.

This is especially true when the decoration is not carried out in a new building, but it is planned, for example, to update the facade of the old house.

In any case, the walls should be prepared:

- Based on the circumstances, you need to remove the old coating, or a layer of plaster; if it is brickwork - clean it from the influx of mortar; plaster the recesses; remove dust from the surface, and soak it with a primer.

- Many believe that cement-sand mortar M50 (1: 5) is quite suitable for laying tiles. But this is not so: as the inter-tile grout is washed out by the rains, the screed, having such low strength, gradually collapses. Tiles, in this case, one after another fall off, or depart from the base layer.

- To prevent this from happening, you need to use specialized glue, which is sold dry in all construction markets. It contains special polymer additives that accelerate the setting and enhance the adhesion of the mixture, make the screed absolutely immune to moisture and resistant to temperature extremes.

- Manufacturers often offer tile glue complete with grout. The price of a bag of glue weighing 25 kg, at least 400 rubles.

Its consumption depends on the thickness of the tile, but on average it is 3.5 kg / m2. A simple calculation will show that one bag is enough for about seven squares of the wall area, and facing even a small house will cost quite expensive. - To save money, but not at the expense of quality, the right solution can be made independently. The ratio of cement in the solution should be done not 1: 5, but 1: 3, and add a plasticizer there.

These additives are sold in cans and plastic bottles. The cost of one liter of plasticizer does not exceed 120 rubles, but it is enough for 100 kg of cement.

This amount will be enough to finish the walls of a small house.

- The order of facing is as follows: a starting profile is mounted on the lower perimeter of the walls, on which the first row of tiles will rest, and gluing it starts from the corners. All types of ceramic facade materials are equipped with additional and corner elements.

When working with a plasticized mixture, moisten the tiles, most likely, will not be needed. Read the manufacturers recommendations carefully.

To make the joints beautiful, of the same thickness, plastic crosses are inserted between the tiles. After the glue hardens, they are removed, and grouting is done. As a result, it should turn out as accurately as in the picture above!

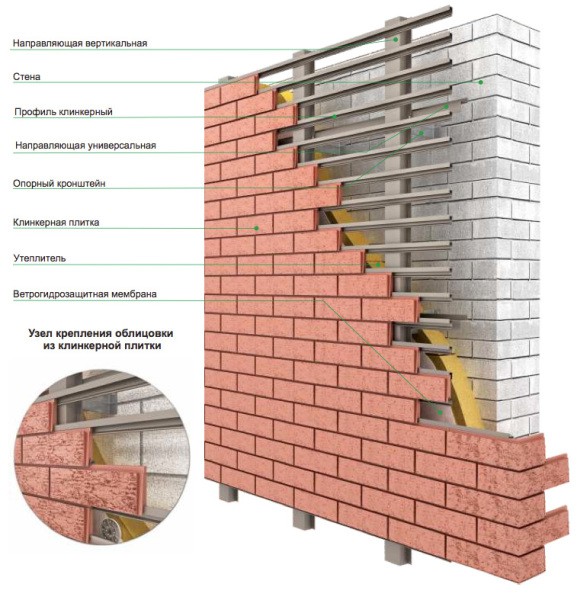

Assembling a ceramic ventilated facade

The success of installing ceramic tiles in the ventilation system depends on the correct installation of the frame, because it will bear the load from the weight of the lining. You can, of course, choose profiles of the right size yourself, and you can, at the same time, manage to slightly reduce costs, but this is the case when it is better not to save, but to purchase all the frame parts of one manufacturer.

So:

- In the kit, as a rule, three types of profile, with Z; L and T-section, brackets, clamps or screws. If it is not planned to insulate the facade, you will only have to buy separately waterproofing (rolled or coated).

For the insulated structure, a heat-insulating material and a windproof membrane will be required.

- At the initial stage of installation, marking of the lines of the starting profile and the location of the brackets is performed. If a roll membrane is used as a waterproofing material, it is glued after the brackets are installed, carefully making slots under them.

It is easier to pre-treat a brick or concrete wall with a deep penetration primer. - Further, vertical racks are installed, and between them, if necessary, heat-insulating plates are laid. The first row of insulation must necessarily rely on a metal profile. During installation, it should be placed on the edges and center on glue, and then firmly fixed with a plate-type dowels.

- After that, wind protection is mounted, and on top of it is a transverse supporting profile that will hold the lining and provide a ventilation gap. It remains only to hang ceramic tiles on the frame. How to do this will depend on which tile you purchased.

Some manufacturers provide mounting tiles on special system mounts. In some cases, the cladding elements have technological holes, and are mounted using decorative screws.

Porcelain tile (seePorcelain cladding: cost estimate), for example, is held on the frame by metal clamps having special protrusions. In any case, the facade, lined with ceramic tiles, or panels, will look respectable and soundly, pleasing with its practicality and beauty.

not bad!!!