Types of facade cladding for every taste

Materials for facing facades of houses are conditionally divided into “wet” and made by panels, blocks. The material of which the house is built plays a role in the choice of elements.

Buildings made of wood require a more thorough approach to this issue; they are more exposed to external influences. What are the facing materials for the facade of houses, we will consider in the proposed article.

The content of the article

Types of decoration for facades

Especially popular are several types finishing materials individual houses.

These include:

- The plaster is decorative finishing.

- The brick is facing.

- Porcelain tile.

- The tile is brick.

- Siding - wooden, vinyl.

- The stone is natural or artificial.

- Cartridges are front.

- Sandwich panels.

- Gypsum.

- Concrete.

- Polystyrene.

- Thermal insulating panels imitating brickwork.

Such materials for facing the facade of the house can be combined.

The use of polyurethane for facades

Polyurethane - a facing facade material, is a modern analogue of gypsum.

It:

- Almost universal new, durable material. With it, you can create complex and variously shaped decorative elements.

- With polyurethane stucco molding, you can create a facade “from scratch” or clad large sections of the wall in a classic style.

- The facade of polyurethane once every 10 years must be painted with water-based facade paint.

Tip: To maintain the original color, the building should be painted after 5-7 years.

- The service life of polyurethane is long, almost the same as the building.

- During the repair, it is necessary to paint, sand, and putty.

- High-quality facade cladding material is hollow inside, but has a high strength comparable to the properties of pine species.

- Lightweight polyurethane, does not make the facade heavier, has good frost resistance, high resistance to alkalis and acids.

- Environmentally friendly material that does not absorb moisture and does not support combustion.

- Elasticity and lightness allow not to deform the structure during operation.

Fiberglass for facades

Fiberglass as a facing material for the facade of the house began to be used recently, but during this time managed to gain popularity among lovers of beauty and luxury. For partial reconstruction or restoration it is an ideal material.

Its main properties:

- Durability.

- Strength.

- Frost resistance.

- Moisture resistance.

- Resistance to weak solutions of alkalis and acids.

- For painting, you can use any facade paint.

- Fiberglass allows you to perform products of any shape on individual orders, while maintaining high precision parts.

Tip: High linear expansion results in cracking of the joints after some time. After that, it is not advisable to repair, it is better to replace the broken element with a new one.

Artificial stone cladding

Fake diamond represents a tile under a natural stone. It is fixed on the screens, gives the house some charm. Well suited for wooden houses.

Installation instructions indicate that:

- To further strengthen the facade, a reinforced mesh is laid on it.

- Screens are mounted on the walls.

- Tiles are laid. Its color, texture and sizes can be very different.

- Tiles can be painted, but not necessary.

- It is a refractory material.

- It has high resistance to moisture and frost.

- It has a long service life.

- It can only be used for strong buildings. Heavy weight greatly increases the load on the building.

- Stones can have a different shape.

- When working with material you need trucks.

Fiberglass cladding

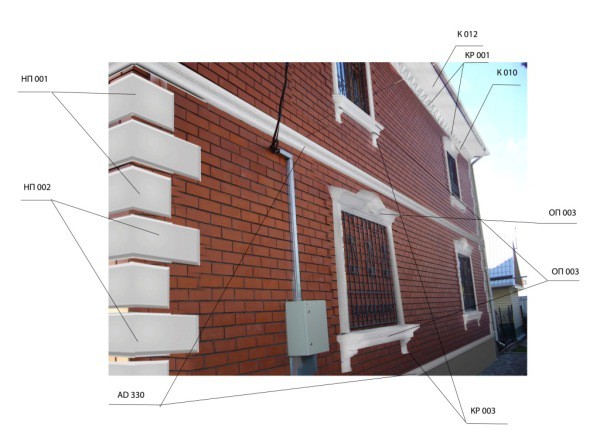

Modern cladding materials for facades include fiberglass concrete. Exclusive details of decoration, ornaments, heraldry, and panels are made from it, which create the effect of "antiquity", which allows using the material during restoration.

Fiberglass concrete panels are used in the design window openings and cornices.

Material properties include:

- Increased fire resistance.

- Resistance to frost and moisture.

- The service life corresponds to the life of the building.

- Fiberglass concrete is lighter than concrete, but heavier than polyurethane, which does not have much effect on the facade of the building.

- Fiberglass reinforcement makes fiberglass concrete much stronger than concrete.

- The material is not susceptible to decay and rust, has a high resistance to harmful chemicals and cracks.

- The disadvantage is that after a maximum of 10 seasons, it will crumble.

Tip: Concrete mortar is used to repair components, and parts can be replaced if necessary. After this, coloring is needed, and re-coloring will be required after 3 years.

Ventilated facade cladding

Mounted ventilated facade - A bright representative of energy-saving technology. Its main task is to increase the heat storage capacity of the wall for maximum heat retention.

If the heat supply source suddenly shuts off, modern materials for facade cladding with an innovative system will create conditions under which the walls will cool several times more slowly than with a layer of thermal insulation inside the room.

The functions of the ventilation façade are:

- Aesthetics. Materials allow you to design facades simply or with elements of luxury.

- Protection of the building envelope. The ventilated system is resistant to vibrations, mechanical damage, humidity drops over a wide temperature range. This prevents the destruction of the facade and the appearance of even invisible cracks.

There are various types of facades cladding:

- A stone with a different gamut of color palette: natural or artificial, which has a base of granite chips.

- Porcelain tile with bright and calm shades and patterns on the surface that mimic the texture of metal, natural stone or leather.

- Vinyl siding is made from lightweight practical polyvinyl chloride. It has good ductility, which allows a long period of time to keep the facade in its original form.

- The metal siding is made of galvanized thin steel with a polymer coating in different styles.

- Decking, manufactured by hot dip galvanizing. In this case, the lined materials for the facades are highly resistant to harmful environmental influences.

- Multilayer sandwich panels are included in the group of the lightest types of cladding, have excellent thermal insulation properties.

There are other types of finishing materials for ventilation facades, giving the building an exterior of a certain architectural style. The photo shows a building lined with vinyl siding.

Numerous advantages of the material allow it to remain among the leaders in demand for a long time.

These include:

- High functionality.

- Great look.

- Practicality.

- Low price.

- Vinyl siding It has an unpretentious, but attractive appearance. In appearance it is a panel made of PVC polymer material, up to one millimeter thick.

- The surface of the material imitates the lining of overlapping boards, has a different color scheme of light tones.

- The length of the panels can reach five meters, width up to 25 cm.

- The connection of siding elements with each other is carried out by a castle system.

- After overlapping installation, the panels are fixed to the base using self-tapping screws.

- Structural strength and ease of laying siding provide special additional elements.

- Mostly PVC panels are used for low-rise buildings: cottages, country houses, shopping centers, gas stations.

How to mount with your own hands any material for facing the facade of a house can be seen in the video. The necessary type of facing material is selected at the design stage of the structure. It depends on the budget, the purpose of the structure, its architectural style.