Facing the facade with a professional sheet - quickly, simply, cheaply, beautifully

What is a professional sheet or corrugated board, everyone knows who carefully looks around. This material is widely used in construction for fencing facilities, roofing, fences and gates.

And recently, facing facades with professional sheet has become very common. What are the advantages of such a finish, how is it made, what other materials and tools are needed for this - read in this article.

The content of the article

The advantages of finishing facades with metal profiled sheet

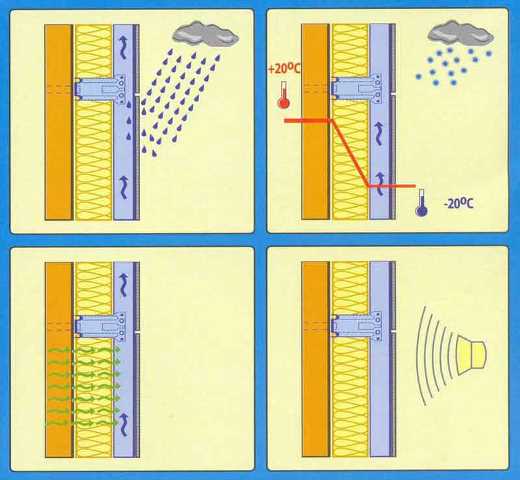

Exterior finish of buildings plays a large role not only in their visual perception. With its help, it is possible to solve several problems at once - to eliminate the influence of external factors on the bearing walls, to insulate the structure, increase its sound insulation, extend the service life. Finally, deprive yourself of dubious pleasure to regularly repair facades.

All this is possible with the right choice of material for cladding. Profiled sheeting, which is a profiled sheet of galvanized steel with a durable polymer coating, is good because it can finish a building built from any material - wood or brick, concrete blocks or SIP panels.

This is possible due to the method of mounting on the frame and the small weight of the cladding, which does not require preliminary strengthening of the walls and strengthening the foundation.

What other advantages does the facade cladding have with a profile:

- The strength of the created surface, its resistance to mechanical damage, shock;

- High degree of resistance to corrosion, moisture, mold reproduction;

- Low price compared to most other facade materials. And this applies both to the profiled sheet itself and to the frame system, which can be made of wooden blocks or metal profiles for the installation of drywall;

- High speed of cladding - due to the large dimensions of the cladding panels and the possibility of their manufacture to order in size;

Tip. When ordering a profiled sheet in production, make careful measurements of the facades beforehand so that each sheet exactly matches the height or width of the facade (depending on the direction of facing chosen). This will allow you to avoid unnecessary joints, and the facade will have a solid look.

- Exceptional ease of installation, which even without special knowledge and experience can be done with your own hands. Which entails another plus - savings on wages of wage workers;

- The ability to increase the operational performance of the building, reduce its energy intensity, by insulating the walls under the lining;

- Possibility of installation at any time of the year;

- A variety of color schemes and their combinations.

This method of decoration, like other types ventilated facades, will allow you to transform even very old and dilapidated buildings, investing in it a minimum of funds. That is why it is often used not only for cladding residential buildings, but also for cladding industrial premises, garages, hangars, sheds, and other outbuildings.

However, this material has some disadvantages. First of all, this is the absence of sound and heat insulation properties. But it is compensated by laying the appropriate materials under the cladding.

There is also a risk of metal corrosion at the points of processing. That is why you need to try not to cut the sheets, but to order them in size.

Facing work

Having decided to use this material for exterior decoration, it is necessary to think over the future design of the building, choose wall corrugated board by color and profile (corrugation height), calculate its quantity and the number of additional elements.

Tip. Additional elements (internal and external corners, slopes, ebbs, framing of window and door openings, etc.) are best ordered after the installation of wall panels. This will allow for finishing measurements and not to make a mistake in size.

Types of Wall Panels

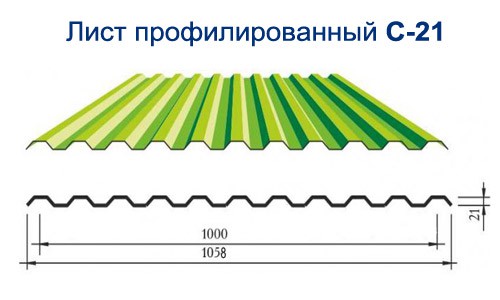

In the manufacture of corrugated board, special marking is used, which indicates the type of material and its geometric parameters. The wall profiled sheet is marked with the letter C, immediately followed by a figure indicating the height of the wave, and then the width and thickness of the sheet in millimeters.

Product length is a variable parameter. It is indicated by the customer, filling out an application for manufacturing.

In the case of the vertical direction of the cladding, it should be equal to the height of the surface being trimmed. The number of sheets is determined by dividing the sum of the lengths of all walls by the useful width of the product.

Example. Marking C21 1000.08 means a wall profiled sheet with a corrugation height of 21 mm. Useful sheet width 1000 mm, thickness 0.8 mm.

Most popular profile for facade cladding has a wave height of 8 to 44 mm. Its varieties are presented in the following table.

| Marking | Application | Profile height mm | Metal thickness mm | Useful width, mm |

| C8 | Wall | 8 | 0,50,60,7 | 1100 |

| C10 | Wall | 10 | 0,50,60,7 | 1100 |

| C18 | Wall | 18 | 0,50,60,7 0,8 | 1000 |

| C21 | Wall | 21 | 0,50,60,7 0,8 | 1000 |

| NS35 | Wall Roofing | 35 | 0,50,60,7 0,8 | 1000 |

| C44 | Wall | 44 | 0,50,60,7 0,8 0,9 1,0 | 1000 |

Its weight and strength depend on the thickness of the sheet, and stiffness depends on the height of the profile.

Installation

In order to prevent the influence of atmospheric phenomena and other aggressive external factors on the bearing walls, the installation instructions for corrugated board, which requires the mandatory installation of an air gap between it and the surface to be coated, must be strictly observed. This layer provides ventilation of structures, prevents the accumulation of condensate, the formation of mold, etc.

It is especially important to observe this condition when decoration of wooden housesmore than others suffering from high humidity. The ventilation gap ensures the dryness of the walls, insulation and the inner surface of the cladding, while maintaining their operational characteristics and extending the service life.

Understand how to properly install corrugated board, you will help the video below and a description of the work:

- After revising the surface of the walls and their necessary repairs (repairing cracks, removing mold, etc.), a frame consisting of brackets and a galvanized metal profile is fastened to them;

Note. For cladding of log or Lumber buildings, it is allowed to make a frame from well-dried wooden bars impregnated with antiseptic compounds.

- The brackets, depending on the material of the walls, are attached to them on screws, dowels or anchor nails. The guide profiles of the frame are installed perpendicular to the direction of the cladding, with a pitch between the axes of about 50 cm and so that they all lie in the same vertical plane.

- If the building needs to be insulated, before mounting the frame rails, the walls are covered with a layer of insulation, which are fastened with plate dowels. Otherwise, they are called mushrooms or umbrellas. The insulation is covered with a wind-moisture protective film;

- The fastening of sheets of corrugated board to the frame is carried out by special self-tapping screws made of galvanized steel with moisture-proof rubber gaskets. They are screwed into the deepened part of the wave. On 1 sq.m. facing 6-10 self-tapping screws are consumed;

- At the end of the lining, measurements are made and additional elements are ordered for finishing openings, curtain rods, building corners.

Often, enterprises that produce professional sheets are also engaged in the manufacture of roof drainage systems. This simplifies their color matching.

Conclusion

The unpainted galvanized profile for facing facades of industrial buildings and warehouses has been used for a very long time. And since our industry mastered the production of polymer-coated corrugated board, it has been actively used in civil engineering, decoration of private residential buildings, shopping centers, public buildings.

The reason for this was the ideal ratio of the cost of material and quality of finished facades, the possibility of implementing a wide variety of design solutions, simplicity and high speed of installation.