How is wall insulation outside a wooden house

In each, separately taken region, there are the most widespread building materials. As a rule, these are the materials that prevail in a given territory.

In our country, it is a forest, which is why there are so many houses built entirely of wood. And many of them stand for many decades, and since the tree is inferior to stone in its characteristics, sooner or later there comes a moment when an old, but still reliable house needs a little restoration.

In this article we will talk about the insulation of walls outside a wooden house, and about the materials with which this can be done.

The content of the article

What to base your choice on

The most difficult task for a modern consumer who wants to build or repair his house is not the price of building materials, it can be matched to almost any budget, and not even a shortage of goods in stores, this concept no longer exists. The main difficulty is to choose exactly what you need in a huge sea of a wide variety of products that differ from each other in all respects, but at the same time fulfill one goal.

Insulation of the walls of a wooden house from the outside is also associated with this complexity. There are many heaters. And each manufacturer praises exactly its product, so who should be preferred (see. We choose materials for wall insulation from the outside)?

To begin with, each material has its own set of not only positive and negative qualities, but also characteristics that need to be selected, starting from the characteristics of your home, and from the tasks that are set. Since we are talking about wooden houses, then for sure, many will prefer materials from natural raw materials, because you want to maintain the environmental friendliness of your house.

We note right away that it will not be easy to do this, since most modern heaters are products of the chemical industry, but do not be afraid, there’s nothing terrible about it, on the contrary, it is the chemical industry that allows you to create materials that meet the highest requirements for practicality , and, oddly enough, for security.

But we will talk about the structure of insulation materials a little lower, but for now let's look at the main parameters that are necessary in order to produce high-quality and durable insulation outside the walls of a wooden house:

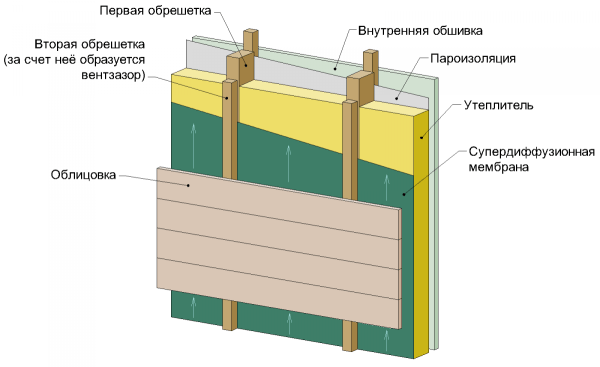

- Steam throughput. One of the most important indicators, especially if we are talking about wooden houses. It is no secret that the main enemy of the tree is constant contact with moisture, and dense heaters do not allow steam to go outside, and due to the temperature difference, it forms condensate that accumulates on the walls, and over time can develop into harmful mold.

- Moisture insulation. Modern heaters are faced with a difficult task - to release steam outside, but at the same time prevent the penetration of moisture under the surface. At first glance, these indicators seem mutually exclusive, but some modern materials can easily cope with this task, and which ones, we will tell a little later.

- Fire safety. Wood, in itself, is a hazardous material that is not very resistant to fire, which is why it is so important that thermal insulation materials not only not support combustion, but also prevent it. Safety should never be neglected, in this case it is an axiom.

- Household Health Safety. Of course, this item could not be mentioned, but many unscrupulous manufacturers have appeared on the modern market who produce truly hazardous materials, and such “comrade” must be weeded out.

- Durability. Repair and facade decoration - it’s a troublesome and not cheap thing, no one wants to redo the repair every two years, so all materials must be of the highest quality and durable.

- Easy installation. Also a very important criterion, especially if you plan to do the repair yourself. Many modern materials are so easy to use that for their installation you will not need either experience or specific knowledge.

Well, and of course, the most important thing for any insulation is a high degree of heat and sound insulation. High-quality materials do not just warm your house, they can significantly reduce heating costs in winter and air conditioning in summer. The benefits can be felt after a year of operation, and the savings can be very, very significant.

So, we sorted out the selection criteria, and we can proceed to a detailed description of the material. We will not dwell in detail on the description of each insulation shown in the photo in this article, and simply divide them into several categories, according to the structure of the material itself.

Soft heaters

Surely, many guessed that we are talking about cotton. Cotton wool insulation has been known for a decade, it used to be glass wool, and everyone remembers the itching and unpleasant sensation on the skin after contact with it. Fortunately, technology does not stand still, and modern cotton wool has become completely different. Now it is an environmentally friendly material, which upon contact does not cause any unpleasant sensations.

All that manufacturers needed was to exclude ground glass from the composition of the material, which caused irritation. To finally dispel all doubts, we note that mineral wool is recommended for builders for use in public and children's institutions, and this already says a lot about this material.

pros

It:

- Vata does not burn and does not support combustion. For interest, you can make a small experiment, and throw mineral wool into the fire, it will not ignite so much, but will also extinguish the flame that appears under it.

- Mineral wool does not hold accumulated condensate, and allows it to completely evaporate, so you can not worry about rot and mold under such a heater.

- Small rodents do not start in mineral wool (see How is insulation of walls outside with mineral wool), for some reason, they simply do not like it, but this is an important aspect, especially for houses of the old construction, where rodents live for many generations.

- Resistance to temperature changes. Due to its structure, cotton wool does not deform when the temperature changes, that is, it does not have thermal deformation and expansion, as is often the case with other types of insulation.

- A light weight. An important criterion, especially if we are talking about houses made of wood, in which the load on the wall structure is undesirable. Vata practically does not lead anything, so it can be used without fear even on light partitions made of plywood or OSB.

Minuses

It:

- Low moisture resistance. Vata not only passes moisture under its surface, but is also able to absorb it and at the same time lose its original form. This factor must be taken into account during installation.

- Not too high degree of thermal insulation compared to other materials. The fact is that during the installation of cotton wool, between the adjacent segments a small gap will inevitably form, and it is in this place that cold bridges begin to form.

As you can see, the disadvantages of this insulation are also present, unfortunately, but not a single material can do without them.

Important! Choose mineral wool only from reliable and time-tested manufacturers. Insulation of low quality often contains harmful substances in its composition, which can adversely affect the health of everyone living in the house.

It should also be noted that cotton wool can also be different. Surely, you met in stores material called basalt wool. This insulation has improved quality characteristics, and it includes natural volcanic basalt, which is why it is much more expensive.

But you should not start saving money for basalt cotton wool, it is most often used to isolate hot elements, such as chimneys or even heating boilers.

Solid insulation

The most popular solid formation insulation is polystyrene (see How is the insulation of the walls with polystyrene foam done outside), a material known to many as packing in the packaging of fragile items. Today it is increasingly being used as an insulating material, as it is able to retain heat for as long as possible, creating something similar to a thermos.

The main disadvantage of polystyrene is that it does not allow moisture to pass, water always remains on its surface without penetrating inside. It is noticed that in houses insulated with foam sheets, very stale and dry air. It is formed due to dense insulation, therefore, such rooms should often be ventilated, or equipped with special forced hoods.

In addition, the flammability of polystyrene often scares off many consumers. We all saw how polystyrene burns beautifully, and at the same time emits thick black smoke and a toxic smell of chemicals. We hasten to please you, a modern polystyrene foam designed specifically for wall insulation contains flame retardants that prevent the material from igniting and cause it to die out even at very high temperatures.

Important! The foam, which contains flame retardants, has a special marking SPB-S, if there is no such marking, this material is combustible and very dangerous, and moreover, it is prohibited by building standards for use in residential and public buildings.

Penoplex

In fact, this is one of the varieties of polystyrene, so we did not give it a separate section of the article. This material is more modern and high-tech. It is produced using the same technology as its older brother, but thanks to some changes, the material is more solid and resistant to all kinds of influences.

Penoplex can be used not only for wall insulation, but also as a substrate for roofing or flooring. It costs, of course, much more expensive than polystyrene, but it has one significant advantage, which sometimes becomes very important. With the same indicators of heat conservation, the thickness of the foam sheet will be much less than that of the foam.

Of course, if we consider the insulation for the exterior walls of a wooden house, then this figure is not so important, but with internal decoration it becomes very significant.

It should also be noted that both foam and polystyrene are very fond of domestic rodents, which form entire colonies inside the walls, therefore it is better to take care of this feature from the very beginning, for example, in stores you can find special compounds that process rough walls. It scares off rodents, and does not give them the opportunity to breed in such an atmosphere.

Advice! When calculating the thickness of insulation for walls, always take a small margin. This is exactly the case when the porridge can not be spoiled with oil.

Liquid insulation

Yes, yes, this is not a typo, modern technologies have come to the point that the insulation for walls outside a wooden house can be in liquid form (see Liquid thermal insulation for walls: features of use).

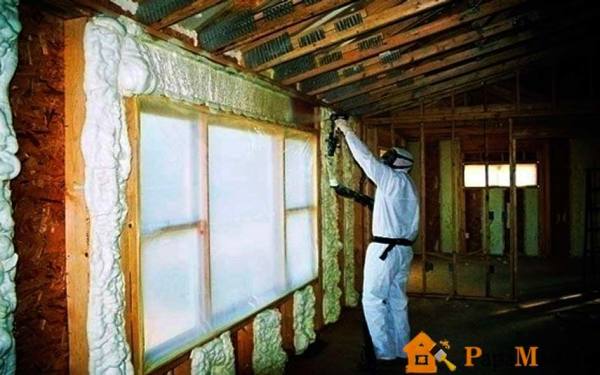

The scientific name of this material is foamed polyurethane foam, or in common people - penoizol. This is the mounting foam used to close the cracks during the installation of windows and doors. It perfectly retains heat and creates a dense coating that is almost impossible to remove afterwards.

It should be noted right away that you will not succeed in applying the polyurethane foam insulation yourself, it requires not only skill and experience, but also special expensive equipment, which is not practical to buy for the first time. In order to clearly understand how the process of applying foam to the walls occurs, we suggest you watch the video in this article, this is not an instruction, but just an orientation video that clearly shows the features of working with this material.

There are several ways to insulate walls with polyurethane:

- Under the facade finish. This method is most often used on brick-lined houses. The craftsmen drill holes around the wall with a span of about a meter, and insert a hose through which foam is fed under high pressure. The complexity of this method in the correct calculation, since after injection, the foam begins to expand, and if its amount was calculated incorrectly, it can simply squeeze out a brick, and subsequently it will be very difficult to fix such a defect.

- Surface application. For houses that will subsequently be sheathed with any material, this method is the most practical. Foam is applied to the wall surface in an even layer, and after it dries, the excess is removed with a knife or even a grinder.

Using the second method, it should be remembered that before applying foam to the wall, it is necessary to collect the crate, which after the whole process will remain in the foam.

If you compare all the materials listed in this article, then penoizol will have the highest characteristics. Of course, it does not let moisture in, and the walls will have to be additionally treated with special impregnations, but given the durability and quality of insulation, this material can certainly be called the most optimal.

The cost of such insulation is also not small, and can often exceed the cost of facade decoration, so polyurethane foam is not suitable for everyone. But if your repair budget can afford it, then you simply can’t find a better isolator.