How is the insulation of the walls of the frame house

Warming of frame walls is almost always done. After all, energy is constantly becoming more expensive and this will contribute to savings.

Today we will tell you how to insulate the walls of a frame house and what materials should be used. Also on the video in this article and photo you can find a lot of additional and necessary information.

The content of the article

Insulation of the frame structure yourself

To ensure the most optimal conditions for maintaining heat in the room, as well as to provide sufficient sound insulation, it is necessary to insulate absolutely all the places through which outside air can enter the room. This includes not only the insulation of walls and floors, but also the space under the roof.

Attention: The thickest insulation should be done precisely on ceilings and under-roof spaces. The difference in the thickness of the insulation with the remaining sections should be greater.

Compliance with this rule will save the necessary warmth and comfort in the house.

Types of existing insulation for frame buildings

All heaters used in construction can be divided into two large types: natural and artificial. Natural heaters are represented by substances and materials found in nature.

These include peat, clay, wood shavings and sawdust. These heaters are rarely used, as they are inferior to more modern synthetic materials, which surpass them in almost all respects. Synthetic materials appeared as a result of the development of chemical technologies.

The artificial heaters used in houses with frame layout include:

- Styrofoam;

- mineral wool;

- polyurethane foam;

- ecowool;

- expanded clay.

All these materials have their own characteristics, including both advantages and disadvantages. We will analyze them in more detail.

Styrofoam

This insulation is considered one of the oldest of the listed. More recently, it was used in the construction of almost every frame house and was considered the best solution (seeHow is the insulation of the walls with polystyrene foam done outside) Most often this was due to a clear deficit of the proposed insulation options in the building materials market.

So:

- Its advantages include a relatively low cost, ease of cutting and styling, lightness and inability to absorb moisture.

- A significant advantage of the foam is the lack of the need for a device to protect it from moisture with special water-absorbing and water-repellent films, which leads to a general reduction in the cost of construction and an increase in installation speed.

There are also some disadvantages of polystyrene foam:

- Increased flammability. Polyfoam is very afraid of fire and quickly lights up. Interacting with an open flame, this insulation is able to release toxic substances very dangerous to human health into the atmosphere;

- Poor sound insulation. In this quality, the foam is significantly inferior to other insulation options, for example, mineral wool;

- Attracts rodents. Rats and mice are able to make moves in the foam, which is extremely negative for the overall solidity of insulation and sound insulation of rooms;

- Weak resistance to mechanical stress. The material requires careful handling during installation, as it is very fragile and it is easy to break, crumble.

Based on the pros and cons, foam can be attributed to the options for budgetary insulation of the building, in which the cost of materials plays an important and largely decisive role, while quality and environmental friendliness can be neglected.

Minvata

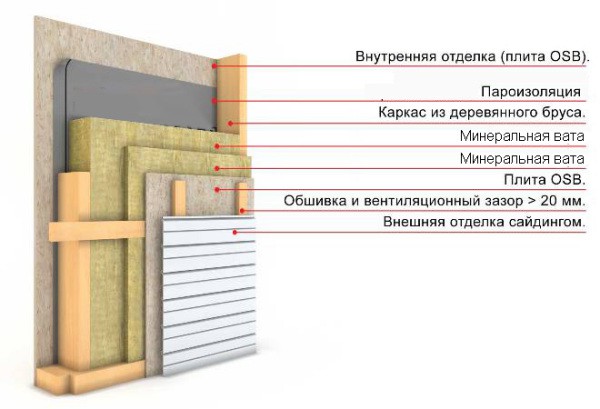

One of the most commonly used insulation materials at present (seeHow is insulation of walls outside with mineral wool) The material is compressed mats that fit inside the walls. The shape of these mats is rectangular, cotton wool is easy to cut with a sharp knife or saw.

The following qualities of mineral wool should be noted:

- Tight packaging that does not take up much space;

- Light weight;

- Excellent sound and heat insulating performance;

- Good burning resistance, long service life.

Against all these advantages, there is one significant minus, namely: the content of small microparticles, the ingress of which into the human body can cause serious diseases.

- The installation process of insulation must be carried out using protective equipment. It is also necessary to protect the interior of the building from flying particles with vapor barrier films or other restraining materials.

- Moisture on this insulation at times reduces its effectiveness. To prevent the destruction of mineral wool, high-quality waterproofing of the walls outside the building should be performed.

- Observing all the necessary installation rules and providing the material with moisture protection, the owner of the house receives high quality insulation and sound insulation. And the incombustibility of the material is sometimes the main impetus for the choice of mineral wool.

Polyurethane foam

It is one of the most modern insulation materials of the last decade. It combines excellent heat-insulating qualities, incombustibility, hydrophobicity and high speed of the insulation process.

- Polyurethane foam is included in the sprayed type of insulation. To obtain it using air, two different components are mixed, which are stored in separate containers until interaction.

- The process of applying to walls and other surfaces is carried out only with the use of special protective equipment, since as a result of the reaction harmful substances are released into the air that can damage human health.

- The main disadvantage of polyurethane foam can be considered its high cost. While warming with foam and mineral wool can be done independently, then for this material it is necessary to use specialized equipment.

Attention: Warming with a polyurethane foam frame house is observed quite rarely, since the high cost of work is considered inappropriate for this type of construction, which involves savings and limited financial capabilities.

Ecowool

This type of insulation incorporates shredded paper, impregnated with special solutions to give certain properties. These solutions protect the material from fires and they are absolutely harmless to the environment and people.

Attention: Ecowool does not need additional protection against moisture with the help of various films and fabrics, which can significantly save and reduce the cost of construction.

This insulation has a number of other advantages, which allows it to be quite popular:

- Soundproofing and soundproofing are at a very high level;

- High resistance to fire and decay;

- Hydrophobicity and lack of shrinkage;

- Complete exclusion of joints, cold bridges.

Of the minuses, it is possible to note the high cost of installation, which is also impossible without the use of narrowly specialized equipment and the call of a team of installers.

There are two ways of finishing the structure with ecowool: “dry” and “wet”. With a “dry” installation, it is possible to carry out work yourself. Not everyone can cope with this, but with certain skills and dexterity, you can achieve the desired result. In the case of using the “wet” method, the solution applied by specialists dries for several days, after which it can be closed with decorative materials.

Expanded clay and similar loose heaters

Warming a house with a frame structure with bulk materials has some nuances that must be taken into account.

- The main problem of expanded clay and materials similar to it is the strong sedimentation, as a result of which previously insulated areas may be unprotected. Voids appear and bridges of cold appear. To avoid such consequences, a thorough and methodical ramming of the material is necessary.

- Expanded clay insulation is best suited for floors. The walls are insulated with it only in those places where the temperature of the external environment rarely drops below minus 20 degrees.

- The material needs high-quality waterproofing from the outside. Moisture will negate almost all the efforts to tamp. Instead of the usual membrane materials, it is recommended to use glassine.

The process of warming with bulk materials is quite laborious and complicated, in contrast to the use of the same mineral wool or polystyrene.

The main criteria when choosing a thermal insulation material

Making insulation of the walls of the frame house, moreover, with your own hands, you must definitely choose the right insulation.

This is done according to the following criteria:

- First of all, it is necessary to consider environmental friendliness and safety for the health of residents.

- You should choose those options that are most weakly exposed to moisture and fire.

- Simplicity and speed of installation are very important.

- The price of insulation must correspond to the level of declared qualities.

- The thermal conductivity of the material should be as low as possible, which allows better heat storage in the building.

- Resistance to mechanical stress, shape retention.

Wall insulation processes

Despite the huge variety of possible insulation options, the main technologies can be distinguished in them:

- Thermal insulation using materials - plates, which include: polystyrene foam, mineral wool and the like;

- Thermal insulation by spraying. A fairly effective way, but due to its novelty and price it is not used as often as the previous one. The process of applying polyurethane foam can be compared with the work of mounting foam;

- Backfill technology. Thermal insulation and sound insulation are carried out with the help of cellulose and other filled materials;

- The technology of combining several options. An example is the following combination: mineral wool is placed in the first layer, then polystyrene foam is applied, after which a plaster layer is applied (seeHow is foam plastering done?).

Thermal insulation technology rules

In the process of building insulation, the main thing is not to violate the prescribed technologies. It is worth paying attention to all the factors that are somehow capable of affecting the quality of the final result. It is important to identify those that improve efficiency, as well as those that can reduce all efforts to zero.

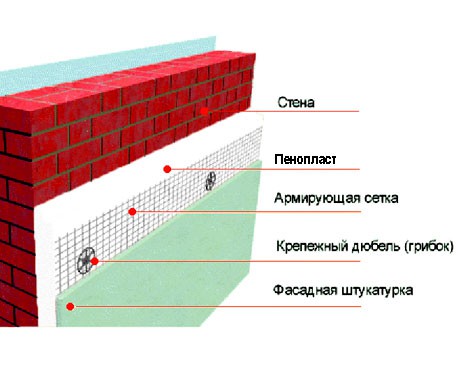

| Hinged insulation method | The waterproofing material and the frame are fixed to the wall surface. Waterproofing can be done by gluing or dyeing.

|

| Wet Protection Method | It is one of the cheapest and at the same time the most laborious methods. On the wall, using synthetic glue, fix the plate insulation, then reinforce material is mounted on the dowels. Then the surface is treated with decorative plaster. The coating is called “light” plaster. |

| "Heavy" plaster | It surpasses the previous version in terms of reliability and service life, but at the same time is inferior in simplicity.

|

| Spray method | The most modern and fast-paced way. Put on the wall by special installations, polyurethane foam has the best performance indicators. Decorating a wall protected by such a heater is possible using almost any materials, including curtain panels. |

| Cladding | One of the most expensive, but also with the most attractive view. Facing is carried out both on the walls of the building, and directly on the insulation itself. The second option significantly increases the quality of insulation, although it implies the presence of good ventilation. |

Basic principles for wall insulation:

- Exact observance of the scheme and order of work, without which to achieve a good result will not work;

- In multilayer systems, the presence of ventilation is necessary to ensure the normal operation of the insulation, protect it from the effects of the atmosphere and increase the service life.

Insulation of walls from the inside

If a situation arises when it is impossible to insulate the building from the outside, insulation from the inside is used. The materials for such work are used the same as for outdoor work, with the exception of mineral wool and glass wool. This is due to the complexity of their use. Most often, extruded polystyrene foam is used here, as well as warming with sprayed materials.

Attention: If in the structure of the frame metal insulation of the internal walls can be done too. Just here you need to choose the right material fastening system.

- Warming is also carried out using plaster, which is coated with putty. Putty is closed with wallpaper or paint.

- Recently, there have been frequent cases of the use of plastic panels, lining, as well as drywall, which is also called dry plaster. A dry coating is applied on top of the dry plaster.

- Penoizol and polyurethane foam can also be used as a protective layer of the house from the inside. These materials are able to fill all voids and smooth out all surface roughness, but their use requires special equipment, which is not always possible.

Additional insulation of the frame wall does not hurt when using any material as a frame. The instruction will help you choose the right insulation and do everything efficiently. The price will depend on the insulation material, but after doing this work all the costs will pay off quickly enough.