We choose materials for wall insulation from the outside

I would like to start this article with the question - what is the basis for most people choosing materials for the construction and decoration of their home? Quality? Longevity? Presentable appearance?

The answer is simple - with all this, and also its cost. We all know very well that the price of many building materials is, to put it mildly, overpriced and not true, but on the other hand, some cheap materials are of very low quality.

So how to combine the notorious concepts cheaply and efficiently? In this article we will talk about materials for wall insulation on the outside of the house, and try to choose the one that most closely matches these two concepts.

The content of the article

What to look for when choosing

The desire to save is inherent in all people, regardless of wealth, it just manifests itself in different ways, and each has its own limitations. Insulation for walls, a material that is very difficult to pick up, because none of us wants to heat the street. The house should maintain a comfortable temperature inside itself, and this is also one of the points of economy, which over the years of operation of the house becomes very significant.

Surely we will not be able to answer the question, what are the best materials for insulation of external walls, they all have their advantages, disadvantages, and technical specifications.

And before moving on to a detailed examination of the most popular and sought-after insulation materials, let's analyze what basic qualities they should have:

- Thermal performance of exterior wall materials. The indicator is different for all materials, which will be discussed below. The choice depends on the materials of the walls and their thickness. Calculating the coefficient yourself is not difficult, just use the calculator program on one of the construction sites.

- Vapor permeability. A very important indicator that does not affect thermal insulation so much, but affects the life of the walls and facade decoration. The fact is that due to the difference in temperature at home and on the street, condensate begins to accumulate on the walls, and if the insulator prevents it from drying out, over time it will turn into a harmful mold or fungus that can affect not only the materials of the walls, but also household health.

- Shape stability under temperature fluctuations. Many materials, with increasing temperature in the street, begin to deform and lose their original shape. The deformation coefficient can be directed both towards decreasing density, and towards increasing it.

- Moisture permeability. At first glance, it may seem that this parameter is the same with vapor permeability, but this is not so. The insulation must release steam and condensate to the outside, but at the same time retain moisture on its surface, preventing it from penetrating inside. It seems like a fairy tale, but many modern materials successfully cope with this task.

- Resistance to fire. Safety is one of the most important criteria. The insulation must have a high fire safety class and not support combustion. Modern building standards oblige manufacturers to produce only high-class products, so all modern materials comply with these standards, and the only problem may arise if you come across an unscrupulous manufacturer.

Important! All modern heaters, to one degree or another, have these qualities, but their ratio is different for everyone, so you need to select materials based on the characteristics of your home, such as the material from which the walls are built, and their thickness.

So, we figured out the characteristics, which means we can proceed to a detailed analysis.

Materials for insulation

It should be noted right away that we do not set out to answer the question of what are the best materials for external wall insulation. Everyone will answer this question independently, but we will only talk about the most popular and sought-after materials on the modern market, and briefly touch upon their characteristic features.

Styrofoam

With this material, we are all familiar from childhood. Previously, it was mainly used as a transport pillow, which protects anything from bumps. Now, it is increasingly being used for external wall insulation, and its main distinguishing feature is its relatively low cost.

Polyfoam is a product of the chemical industry, made from polymers with the addition of freon, which completely evaporates in the process, leaving small granules that are bonded together and are called polystyrene (see How is warming the walls with foam yourself).

Interestingly, over time, polystyrene gained completely new qualities that he did not have before, and the most important of them is incombustibility. We all remember how beautifully the old polystyrene burned. It melted, dripped, emitted an unpleasant odor, and emitted acrid toxic smoke.

Modern technologies have made it fully resistant to fire. Now it deforms under the influence of high temperatures, contracts, but does not support combustion.

Important! Not all foam is non-combustible. The material, which includes the same flame retardants that prevent fire, is marked PSB-S. If there is no letter C at the end of the abbreviation, this material is combustible.

As for the shortcomings of the foam, in fact, there are several more than the advantages, and most importantly - this is low vapor permeability. Since the material is a polymer, it is not capable of releasing moisture outside, and accumulates it underneath. But why is he so popular? Is it really just because of the price?

No, the fact is that if the walls of your house are built of ceramic bricks and have a thickness of about 20 centimeters, then it is quite possible to use polystyrene as a heater.

Condensation practically does not accumulate on such walls, and its small amount does not grow into mold if the facade is treated with special primers or impregnation of deep penetration, which create a special microenvironment in which harmful bacteria are unable to multiply.

Penoplex

A new word in the field of insulation of walls, roofs and even floors. Penoplex is one of the varieties of foam, but unlike it, it has a denser structure and is able to withstand significant surface loads. The foam is made from the same materials as the foam, but using a completely different technology, and looks like large segments of orange or red.

In fact, it can be called the best material for insulation of external walls, because of its high quality characteristics, and here are just a few of them:

- High vapor permeability. Despite the density, penoplex has the ability to "breathe", which allows it to completely remove moisture from under its surface.

- Moisture resistant. This material does not absorb moisture at all, and does not allow it to penetrate inside. Even constant contact with water for penoplex is not a problem.

- Lack of temperature deformations. Penoplex does not warp under the scorching rays of the sun, and it easily tolerates even the most severe frosts.

- Fire safety. The material is completely non-combustible, and can be used even on buildings where increased attention is paid to safety, for example, public or children's institutions.

- Environmental friendliness. Despite the fact that penoplex is a derivative of chemical polymers, it is completely safe for health, and moreover, the Builders Association recommends it for use in the construction of public buildings.

- High coefficient of thermal protection. The density of the foam allows even the thinnest walls to warm them, so it is often used when decorating balconies or summer houses, where the walls are initially thin, and making them thicker is not possible.

Unfortunately, there are some disadvantages, the main of which is the high cost of the material. The fact is that the production of foam plastic is a complex and lengthy process that requires special equipment, and in our country there are very few such manufacturing companies, which, ultimately, affects the price. But if your financial issue is not so acute, then you will not find a heater better than penoplex, at least for now.

Polyurethane foam

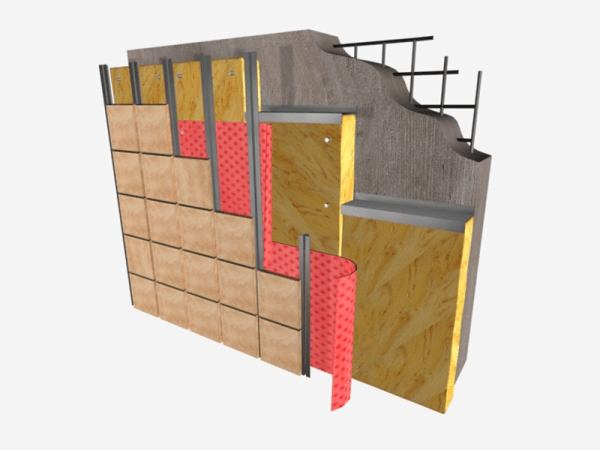

And again, the material for wall insulation on the outside is based on foam, but only in this case we are not talking about sheet segments that are attached directly to the wall, but about real foam, which is also often called assembly or simply foam insulation (see Liquid thermal insulation for walls: features of use) Surely, many, having started reading the description of this material, imagined the very foam in spray cans that can be found in any hardware store, but if we are talking about wall insulation, the application process looks somewhat different.

It should be noted right away that it is unlikely that you can do it yourself with your own hands, unless of course you are ready to put about one hundred thousand rubles on equipment that you use only once in a lifetime. This equipment consists of two containers containing chemical components that, when connected, create the same foam. It is applied using a powerful spray, which also serves as a mixer.

We will not describe in detail the entire process of applying polyurethane foam, and just suggest you watch the video in this article, which shows this whole process and provides instructions for working with this material.

As for the qualitative characteristics of polyurethane foam, then it, along with foam can be classified as the best materials used for wall insulation from the outside. The main advantage here is the integrity of the coating. There are no gaps in the foam layer, which means there will be no cold bridges afterwards.

Well, if we talk about the shortcomings, then this is again the price, or rather the services of people who are involved in applying penoizol to the walls. This process is lengthy and complex, and as a result expensive.

Vata

Not all wall insulation materials on the outside have a foam base, and of course, we could not ignore mineral wool. We all remember glass wool, which several decades ago was used as a heater for heating mains. After contact with her, irritation and itching appeared on the skin, and everyone was very afraid of her.

Modern mineral wool looks exactly like glass wool, and therefore many still have a stereotype of its harm. In fact, everything is completely wrong, mineral wool is produced using completely different technologies, and there is no glass in its composition, which means that it does not cause irritation on the skin.

Such cotton wool is very often used as insulation for walls, and among its main advantages, one can distinguish relatively low cost and complete safety, both in terms of ecology and fire.

Vata is able to tolerate any temperature and does not support combustion at all, but at very high temperatures it can lose its original qualities. That is why, if you need, for example, insulation chimney, it is better to use the so-called basalt cotton wool, which in its composition contains particles of natural rock. Such a heater is not afraid of anything at all, although it costs a little more.

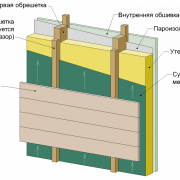

There is another complication associated with mineral wool, namely, the method of its installation. The fact is that this insulation, unlike polystyrene or polystyrene, does not have a stable structure, and can simply crumple when moisture is collected. To prevent this from happening, installation should be made, always taking into account this factor.

Fastening takes place on special plastic dowels with a wide hat, and the more there are, the denser and better the insulation will be.

In fact, mineral wool is one of the most popular heat insulators to date, with its help they insulate not only walls, but also under-roof spaces, which tend to freeze strongly in great frosts.

And in conclusion

So, did we answer the question, what is the best insulation of the walls? Probably not. And is there an answer to this question at all? Too many factors must be considered when choosing a heater. Here, the material of the walls, and their thickness, and climatic conditions in a single region.

One thing is certain with certainty - one must approach the choice of insulation material with all responsibility so as not to subsequently heat the street in winter, and not to cool it in the summer. The flow of heat carriers will largely depend on the right choice, and in some northern regions of our country this is one of the most significant items of family budget expenditures.