How is insulation of walls outside with mineral wool

Insulation of walls with mineral wool outside is most common. This material has good insulation performance, it attaches itself perfectly and the price is not high.

Today we will consider how insulation of the external walls with mineral wool is done and how to prevent mistakes when doing the work. Also on the video in this article and photo you can see the most critical areas of work.

The content of the article

Characteristic features of mineral wool

Mineral wool insulation of external walls is one of the most popular insulation options and is available for any type of housing, whether it is an apartment on the fifteenth floor or a private house in the village. Mineral wool can be called the most famous heat-insulating material for external insulation.

In fact, the term mineral wool refers to four materials, and not one:

- Cotton wool from slag;

- Fiberglass;

- Cotton wool from basalt;

- Stone wool;

Minvata, depending on the feedstock, has a different fibrillation, which is set technologically: with horizontal or vertical direction of the fibers, corrugated and spatial type.

This material is made of glass by heating and drawing it into a very thin fiber. The gluing substance that holds together a piece of mineral wool is resin (there is no negative effect on the human body from these resins).

A type of mineral wool, features

Wall insulation from the outside with mineral wool is done according to your requirements. After all, it is eaten by several species and they are different in their technical parameters. Let's get to know them better.

Glass

For its production, limestone, sand, soda and borax are used, i.e. the same as in the manufacture of glass.

Advantages:

- Does not catch fire;

- Excellent soundproofing;

- Resistance to low temperatures;

- No shrinkage.

Attention: But there is also a minus of this cotton wool - a fragile structure. Fibers, upon contact with the skin, cause very severe itching. It is undesirable for these fibers to get into the eyes and lungs. Therefore, work with this cotton wool is necessary only in overalls, goggles and a respirator.

Stone

It is made by melting rocks: dolomite, basalt, limestone, etc. This cotton wool is not hygroscopic, does not burn, good sound absorption, eco-friendly, durable, no shrinkage and no taunting like glass wool. The best characteristics of one of the subspecies is basalt wool.

From toxins

The raw material for the manufacture of this type of wool is the remains of slag after blast furnace metallurgy. One plus of this material is low cost.

Disadvantages:

- Not durable;

- High hygroscopicity;

- Low heat conductivity;

- The fibers are brittle and sharp, like glass wool;

- The composition of the fibers is a residual acidic medium, an acid-forming process is activated in a moist environment, and an aggressive environment will arise for metals. That's why this type of insulation is not at all suitable for insulation of house facades.

These are the most common types of insulation, there are several more types.

Do I need external insulation

There is no special need for external thermal insulation, unless as a safety insulation.

Thermal insulation of the walls of buildings with mineral wool is an excellent solution, due to the excellent working qualities of this material:

- Minimum heat conductivity;

- Fire resistance;

- High-quality soundproofing;

- Environmental friendliness;

- Installation of insulation with material is very simple from the outside, but from the inside it will require some skill;

- Resistance to biological and chemical substances;

- Low hygroscopicity;

- Light in weight;

- Durability;

- Cheapness.

Disadvantages when performing facade insulation are sometimes called difficulties with independent insulation and the influence of climate features. From which it follows that thermal insulation, both external and internal, is considered a more effective option. If you carefully follow the process, self-installation of thermal insulation of the walls can be performed at a high level in any direction.

Advantages of external insulation:

- The volume of premises from the inside is not reduced;

- An opportunity to make warming of a long rebuilt building;

- With external thermal insulation, the internal premises are not affected;

- The appearance of the building can be any;

- With temperature fluctuations, a “shock” is taken over by the heat-insulating laying, the walls of the building are practically not affected, which means that they are minimally deformed, as a result, the service life increases.

Attention: When laying, the width of the thermal insulation gasket is not allowed less than 100 mm. The best solution is to fix the insulation on the external wall and cover it with brickwork. As a result, the insulation will be internal.

The installation process of the insulation layer

The technology of wall insulation with mineral wool is not complicated from the outside, but it has its own characteristics. We must do everything in a certain order and apply high-quality materials.

So:

- Minvata tiles are mounted throughout the facade;

- The insulation layer is fixed with fixing anchors, by drilling them;

- Insulation boards are mounted on the anchor, and anchor fasteners are locked with clamps on the outer layer of insulation;

- Next, brick masonry is carried out;

- Wipe all joints with cement grout or material decorative plaster.

There is a minus in this technology: it is used only in the construction of a building. What to do if the building is already rebuilt, but it is necessary to perform thermal insulation work?

Minvata has a number of advantages over other heaters:

- The ability to completely fill gaps and voids. When using foam as a heat-insulating pad, this effect cannot be achieved. In addition, the foam is often bitten by mice, they bypass mineral wool and, due to the absence of gaps, rodents simply have nowhere to come from.

- If the outer heat-insulating layer is made of mineral wool, then laying of a film for vapor barrier is not required.

- Refractoriness, resistance to extreme temperatures and does not participate in the combustion process.

To lay the insulation layer does not require special knowledge and qualifications, anyone can independently insulate the walls using mineral wool for this. But it should be noted that the operational life and quality of the thickness of the insulation layer will depend on the preparation of the walls for further insulation and installation work.

How to insulate the exterior walls of a building

There are several methods of wall insulation using mineral wool:

- Location of thermal insulation in the "well";

- “Wet” thermal insulation, with gluing;

- Ventilated facade system.

In the “well” system, a heat-insulating gasket is located between the wall and the facing material, for example, brick, cellular concrete. Thermal insulation - mineral wool, locked in the wall.

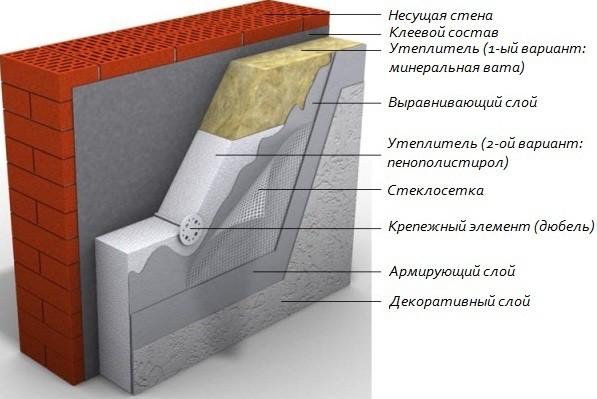

With the “wet” method, the insulating material is attached to the walls by gluing, additionally it is attached with dowels. Overlay reinforcing mesh and then several layers of coatings.

Stages of warming:

- Thoroughly prepare surfaces, clean and close up all wall defects;

- Fix the basement cornice;

- Stick on insulation boards;

- The dowels are additionally secured with a layer;

- Stick on the reinforcement network;

- Primed;

- Apply an intermediate or topcoat for the walls;

- Staining.

Attention: Fragments of mineral wool are glued with a special adhesive mixture, which is prepared according to the manufacturer's instructions. The mixture is diluted with water to obtain a mass with a creamy state. Be sure to check the compatibility of the adhesive mixture and the material.

The “wet” method is suitable for “stone” walls: concrete, brick. If the walls are frame or wood, then insulation must be done in another way.

The ventilated facade system is suitable for various types of external walls - from aerated concrete (see Aerated concrete bearing walls: do-it-yourself masonry), wooden, brick, concrete. According to the technology, the frame is made, in its "cells" are placed the squares of mineral wool, which must be laid with maximum density.

They are glued to the wall with special adhesive masses and additionally fixed with a dowel. The advantage of this technology is that it is not necessary to seal the layer with a vapor-insulating material. The gap, intentionally left between the facing layer and the insulation material, ventilates the air and shifts the “dew point” beyond the walls and the insulation layer. The heat-insulating gasket from mineral wool does not get wet and does not shrink.

Mineral wool fastening

Plates of mineral wool are laid on the walls and carefully pressed. Further, each plate is glued so that there are no gaps and gaps between it and the previous plate, and “cold bridges” do not appear.

If there are gaps, then they need to be repaired with small fragments of insulation. In order to enhance the reliability of fastening plates, they, in addition, are strengthened with dowels. They are attached to all four points of the insulation plate with the ability to capture adjacent tiles.

Attention: An indispensable requirement when installing the insulating layer for insulation work from the outside is to ensure free access of air. A prerequisite is that the “dew point” does not fall into the thickness of the insulation layer, because this will lead to the accumulation of moisture inside the mineral wool, its deformation and loss of performance.

If the process is carried out correctly, wall insulation from the outside with mineral wool will provide heat in winter and cool in summer. A good control during the installation of insulation material will make it possible to be sure that the thermal insulation layer will last a long time and there is no need to pay extra for a comfortable stay. The instruction will help you do everything correctly and efficiently.