How is wall polystyrene insulation

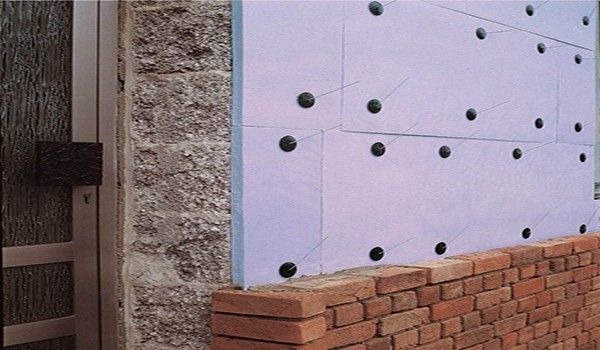

Polyfoam or polystyrene foam for warming a brick wall is used quite often. It has an attractive price and excellent features. It is also quite possible to insulate the wall with expanded polystyrene with your own hands, and this is already a guarantee of the quality of the work.

Today we will tell you how to insulate the walls of buildings with polystyrene foam and polystyrene. Also in the video in this article and photo you can see the most time-consuming areas of work and do everything right.

The content of the article

Insulation technology

Do-it-yourself insulation of a brick wall with extruded polystyrene foam or expanded polystyrene is practically the same. It is important to use high-quality materials and comply with the technology of work.

Let's take a closer look at how insulation with polystyrene walls is done:

- Before starting the process of insulation, you need to clean the exterior walls of all the excess, because this interferes with the work. We are talking about gratings, pipes, ventilation, wires, etc. With old brick buildings, decorations on the facade usually interfere. Just it will be necessary to get rid of them in order for the work to be done efficiently.

- You will need to check the strength of the plaster, but for this just knock. Of course, if it is not, it will facilitate the work. It is important to find uneven places using a plumb bob or other similar tools. In order not to miss anything, it is better to immediately mark with chalk. As practice shows, after verification there is always something to work on.

- Often the walls are either uneven, or the plaster is about to fall on your head (seeHow to strengthen the crumbling plaster with your own hands). With such serious shortcomings, it is better to postpone the work. Before warming, it is important to get rid of unnecessary bumps on the wall and remove pieces of interfering plaster.

Note: Pay attention to the painting of the facade. If it has oil paint, it is extremely important to get rid of it. It must be peeled off, because otherwise the adhesive properties of the surface itself will decrease. In addition to paint, there is fungus, grease, rust, saline deposits, etc. Just also have to get rid of it.

- For large cracks or other irregularities, a primer must be used (seeTypes of construction primers and their scope). For this type of work, the macklower tool and deep penetration material are used. In this way, the work process runs much faster and more accurately. After the primer, cement putty is applied. It is necessary for outdoor work so that cracks are puttied. When irregularities do not correspond to the required size, they are primed. After that, the plaster is applied to the placed beacons. For a brick wall, it is applied once, and for concrete - two. For coating use a tool roller or brush.

- It is not necessary to get rid of communications if they can be covered with insulation materials. Only before this is to make a plan for the placement of wires, and only then deal with the coating.

Start of work

Before you start, you need to calculate the lower boundary of the wall, and then proceed with the foam insulation:

- The hydraulic level needs to measure the boundary at the inner and outer corners. We pull the cord along the marked points. On the selected lines, the first profile starts. Thanks to the first profile, the bottom row of insulation material will be held.Plates can move from the place due to the fact that the glue does not have time to dry quickly.

- The size of the first strip depends on the width of the heat insulator. To fix it, use a dowel-nails. They are nailed every 35 centimeters. Dowel nails are bursting with a type of driven nails. A washer is put on a driven nail.

- The joints of the first strip are either oblique with a cut, or an angular connector is applied to them. Sometimes temperature can adversely affect the structure and ultimately deform it. In order to somehow prevent this, you need to place a plastic connecting element between the profiles. It is very important not to overlap profiles.

The process of preparing the adhesive mixture

Caution: A good glue has the property of drying quickly. Therefore, it will be better if the work lasts up to two hours.

- To save time, the amount of adhesive mixture is best determined on site. We do this with the help of water poured into a bucket. Then pour a sufficient amount of adhesive into it.

- Our goal is to achieve a suitable adhesive mixture without lumps. To do this, use a drill with a special nozzle, which acts as a mixer. After that, the glue will rise for five minutes as a dough.

- You may need to mix several times to achieve the best result. If the glue will gradually thicken, you can reuse the “blender”, but do not add water.

Foam adhesive

The technology for applying glue to the foam board is very diverse. In particular, it all depends on the walls.

There are three ways:

- Glue is applied on all sides of the foam without going abroad (2 centimeters from the edge). The thickness of the adhesive mixture is two centimeters. Glue beacons are used in the center of the plate, which insures the plate in case of sagging. They are laid on an area of 0.5 square meters in an amount of up to 7 pieces. Each of them has a diameter of about 10 centimeters. This method is used for surface drops of 1.5 centimeters.

- The second method is applicable in the case of irregularities of less than one centimeter. Glue is applied to the foam plate in the center and along the perimeter. The width of the applied glue should be up to 4 centimeters. It is important that the foam board is 60 percent covered to the top. This is necessary so that when the plate is pressed, the adhesive will flow evenly throughout the material.

Caution: Apply glue with a dashed line, but not with solid stripes. In this case, air congestion can be avoided.

- The third method is applicable for almost even walls. Glue should be applied to the base of the plate with a notched trowel (the size of the teeth should be 1x1 centimeter).

When there is glue on the plates, you must immediately begin the process of work. First, polystyrene foam boards are applied.

Before gluing such a plate to the desired area, it is slightly shifted from the right place by two to three centimeters. Then the insulation plate is pressed to other plates in accordance with the building rule. Removed glue on the sides or corners must be removed immediately.

How to install a foam plate

Insulate the wall with polystyrene foam and polystyrene (seeHow is warming the walls with foam yourself) can be qualitatively only with the correct and even fastening of sheets. To properly install the stove, you need to use the level. In addition to it, it will be wise to use a control cord and a building rule to determine deviations from the plane.

- Each plate should fit tightly at a distance of 2 millimeters. If the distance is more than necessary, you will have to close these gaps between the plates. For this, construction foam or smaller pieces of foam are great. Seams should not contain glue. Docking points should not be thicker than 3 millimeters.

Attention: It happens that the first time the plate was mistakenly placed.In this case, it is not recommended to move it, but it is better to completely remove it and re-coat with glue (of course, the stove must be cleaned of the old mixture).

- Installation of insulation materials is carried out from bottom to top. The success of the work process will depend on the bottom row. In order to prevent errors during the installation process, you must first glue the first and last foam plate. And already glue other plates on them, guided by the stretched cord. And so gradually rise shifting the joints no more than twenty millimeters. You can use the chess method of shifting plates. In this case, one plate is shifted by half.

- Particular attention should be paid to the docking in the area of windows and doors. Do not allow vertical slopes. The joint should pass either under the opening or above it. When insulating the facade, the displacement should be at least 20 centimeters.

- Sometimes it happens that the insulated wall can be built of two materials. That is, one side is brick and the other is foam concrete. This means that the insulation boards need to be joined at least 10 centimeters from their border. With recesses or protrusions, an offset of 10 centimeters is also calculated.

- The connection of plates in corner places is carried out by teeth and with dressing. In order to avoid a long seam, the insulation goes onto an adjacent wall. Also, a supply of foam plate at corners or slopes is needed (needed for dressing). However, the excess part of the plate can be disposed of as soon as it fully adheres. The excess part of the foam is cut wide with a knife or a thin file with cloves. To cut straight, you need to apply a ruler.

- Slopes are insulated close to the door or window opening. Usually for such an installation, polyurethane foam tape or an adjacent profile is used. The tape is needed so that it can be glued to the door frame. Adjacent insulation compresses the tape three times. On the window frame along the facade, it winds up no less than 2 centimeters. The window opening can be pre-glued with an adjacent profile.

Sometimes on the wall expansion joints can come across. In this case, make a gap of up to 1.2 centimeters. After that, a polyethylene cord is inserted into it and squeezed three times. And then you can glue the insulation plate.

Attachment points

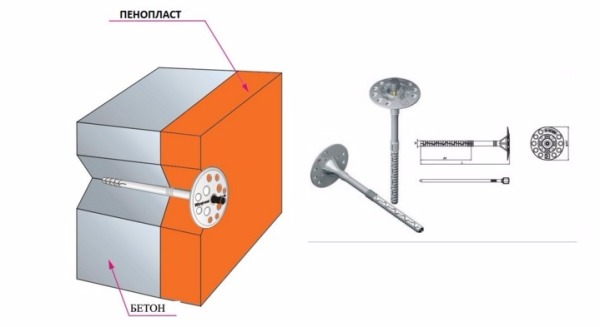

Insulation of a brick wall with polystyrene foam or concrete is done taking into account the rigid connection of the foam with the base plane.

Professionals recommend arranging holes in the following order:

- In the center and at the joints of the foam plate. In total, there are 6 fungi (more can be done only if needed).

- Often the walls are not even, so if you try to nail the first fungus in the center, the sheets can rise on the sides. And it is important for us that the sheet is glued evenly and tightly. To do this, you need to nail more fungi.

- Fungi are inserted and clogged when the holes are drilled. They are clogged with a hammer (in rare cases, you can hand). It is important that the cap of the fungus is flush with the plane of the foam sheet. If this norm is absent, and the mushroom cap does not lie close to the surface, then the drill is cut off or the hole does not have the desired length. In this case, you will have to drill and re-drive the mushroom

- After clogging the fungi, nails are clogged. At this point, the fungus can move inward, but that's okay. The immersion length of the clogged mushroom should be no more than two millimeters. When the nail sticks out, it is recommended to cut it with a wire cutter.

How are joints of heaters and fungi processed

When the wall insulation with extruded polystyrene is done, it is necessary to carry out the processing of the plane.

Thereafter:

- It is important to pay attention to the distance of the joints between the sheets (the distance should be no more than 5 mm). If the norm is exceeded, it is necessary to foam this area of joints.With a large distance (up to 2 cm), you need to insert the remaining pieces of foam and also foam.

- After the foam dries (4-5 hours), it is necessary to remove its remains.

- If the joints stick out and spoil the appearance, they can be removed with a grater.

- In addition to polystyrene, a material such as Epps is used. It is much harder and can not be trimmed with an ordinary grater. To align the joints using a clerical knife.

- At the last stage, joints and fungi are pulled by an adhesive mixture (a spatula is used). For the constriction to be of high quality, all places must be level. After everything dries, excess pieces of materials may remain. To clean them, use a large spatula.

The technology for warming floors and walls with polystyrene foam is somewhat different; there are separate articles on our site on the topic of floor heating. Other materials can be used for floors, so for a start you should study this issue in more detail.