How is warming a brick wall from the inside

How to properly insulate a brick wall from the inside, we will consider today in detail. After all, this option of warming is quite common. True, it is worth saying that in some cases it will not work.

How to insulate a brick wall from the inside, which materials should be used, we will consider below. Also on the video in this article and photo you can see the most difficult moments of this work.

The content of the article

Rules for warming brick walls

Insulating the partitions of a building is a task that is of great importance in the intention of retaining heat in living rooms.

These works can be performed both inside the residential complex and from the outside:

- Street insulation is used at some points, if the house is perennial and needs to be finished, it is possible to cover either the base, or from blocks and wood. External insulation is preferable, as it is solid and easier to work than inside. After such insulation, the room inside will not become smaller in area, does not need an auxiliary ventilation hatch and does not form a “greenhouse” inside the house.

- If the premises were erected the other day, the walls are made of not cheap and attractive brick, or the outer covering of the house is not allowed due to the conservation of the building's architectural appearance, it is preferable to use insulation from the inside (see Thermal insulation of walls from the inside: we choose materials).

- In addition, indoor insulation is carried out if it is not possible to carry out such actions from outside only one wall in a perennial building with many apartments, but does not meet current requirements for heat protection. Then it is necessary to insulate the entire building from the outside to maintain heat, because exceptional insulation will not give much benefit.

Attention: Do not forget that the insulation in the middle reduces the area, but at the same time makes up for other advantages of this method.

The internal insulation of the room is not so expensive compared to the external, besides, certain permissions are not required to carry out these actions, and you also do not need to call professionals of this kind of work.

If you decide to make insulation in the middle of the room, then you should take into account other kinds of problems that may appear at the time of work.

Features of brick walls

Brick walls differ from walls made of concrete floors and wood, with peculiar features:

- Firstly, on the walls can be used both hollow and solid bricks. This greatly affects the heat conductivity of the brick wall, the location of this result between the tree is 0.2 W / (m.K) and concrete 1.5 V.t / (m.K) and forms 0.4 W / (m.K).

- SecondlyBrick laying can be continuous or atmospheric recess (masonry well). The wall corpulence changes depending on the type of masonry itself and the application of a brick discharge, while the use of parameters and the desired completeness of the thermal insulation cover change.

Note: Previously provided average heat conductivity data. The parameters of heat conduction can vary in different directions, this is from the applicable varieties of timber and raw materials for manufacturing.Thus, the concrete in which expanded clay was added conducts heat 0.66 W / (m.K), silicate brick is solid 0.7 W / (m.K), and the pine tree 0.09 W / (m.K). You need to have information about what the walls are built and their thickness before starting to isolate the walls of the room.

- Regarding the masonry method, it should be noted that in the case of continuous laying, the material is distributed over the entire space of the wall or from one or both sides. The layer is directly related to the thickness of the wall: not a large layer is needed on a thick wall.

- If the masonry is “well-shaped” then the material is placed in the middle of the wall, in the middle of the brick. This direction has the name - wall insulation. This method can guarantee auxiliary heat insulation by means of an atmospheric layer between the outer and inner walls, but if you use a heat-insulating substance, the heat loss will be minimal.

The main problem of thermal insulation

The insulation of brick walls from the inside with their own hands should be carried out according to the technology, because in this matter the important role is played by condensate, which appears between the wall and the applied insulation.

Attention: If the actions were not carried out properly, then the manifestation of moisture will be visible after a short period of time. The resulting condensate will damage not only the insulation, but also all the finishing materials that were used to process the room.

- First, moisture penetrated into the insulation reduces its quality, as an insulator at times.

- Secondly, humidity is the culprit in the occurrence of moldiness or penicillium, which very badly affects the activity of the entire structure of insulation, as well as the well-being of people and animals in the house.

- In the end, dampness, settling on the surface in the middle of the room, accompanies the destruction of substances, thereby undermining the quality of insulation, but the building itself will not stand for a long time.

For the correct installation of the insulation and the correct determination of the level of its fastening, it will be necessary to make the necessary calculations.

- The calculation is done in two ways: it is primarily determined by the dew point. With its location on the wall, you will never have problems with the level of placement of insulation. If it is located in the insulation or on the outside of the wall, then internal insulation can simply not be done.

- To insulate the room from the middle, use a variety of building materials. More preferred options are the use of polystyrene, polystyrene foam, stucco, mineral wool (seeMaterial for wall insulation inside: characteristics) Sometimes cork panels, concrete platforms with designed heat-insulating fillers, etc. are used.

Let's look at how to insulate a brick wall from the inside in more detail and go through the basic materials.

Applicable Materials

Let's immediately look at the most used materials to date:

| Polyfoam or expanded polystyrene for warming | Publicly available, common and tested insulation of the room. Polystyrene foam materials (polystyrene foam, polystyrene foam, polystyrene foam) are often used as an insulator of walls from the inside, and brickwork is also included here.

The only downside is that a lot of space is required for polystyrene. If there is no problem with the size of the area, then keeping foam heat is a great option. |

| Thermal insulation plaster | The method tested by time is the insulation of walls made of bricks using plaster mortar.

|

| Mineral wool insulation | Serving as a non-conductor, mineral wool is known from a good side, and is energetically used for insulation both from the middle of the room and from the outside.

|

Options for internal wall insulation

It is worth remembering that the insulation of internal surfaces with a heat-insulating layer is the last option of insulation, which requires attention, only if it is not possible to make insulation from the outside.

Caution: Awareness or recklessness in this matter may aggravate, rather than improve, living conditions.

Wireframe method

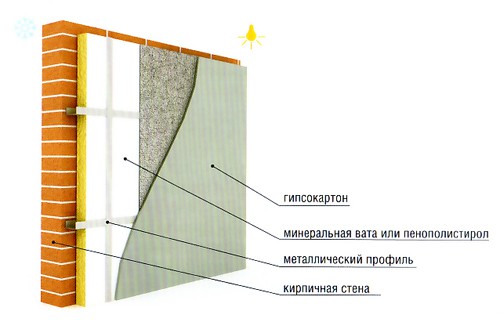

The first option is quite complicated and not everyone can do it with their own hands. Most professionals recommend insulating walls from the inside, using a metal frame on which drywall is attached.

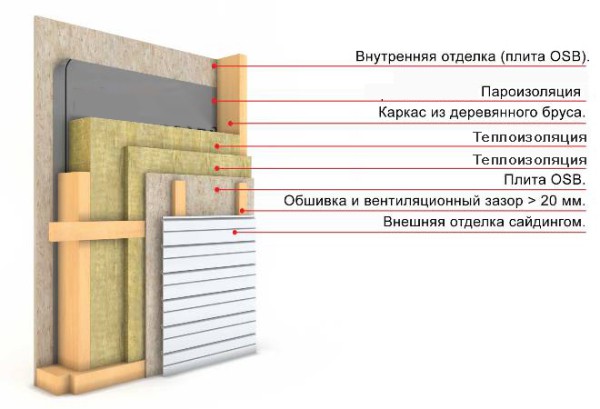

- Material (for example, mineral wool slabs) lies in the middle of the base and surface. On top of the base and the insulator, a parasitic membrane is formed, forming an airtight layer. The membrane serves to protect the coating from moisture.

- In the middle of the thermal insulation structure and in the finishing cavity, it is required to leave a distance of a couple of centimeters for ventilation. This gap will provide a second foundation built on top of the first. As a result, a structure comes out of more than one layer, consisting of two bases, an insulator, a parasol membrane and drywall or other sources of coating.

Insulation without frame

The second option to mount heat insulation is much simpler and more profitable. They propose to use it when action needs to be done quickly, but there is not enough finance.

So:

- The walls are cleaned of the finishing base, because the insulator will sit on the glue, directly on the wall. Polyfoam plays the role of a heat-insulating substance. Polyfoam is not an expensive and profitable insulator (see How to use polystyrene for insulation of walls inside the house).

- First you need to plaster the surface, then when it dries, putty the walls. After the putty dries, lay down the waterproofing, which will serve as a protection against moisture. If the foam gets wet, it loses its potential as a heat insulator.

- Glue is used on the wall in large quantities. Polyfoam is hermetically pressed against the wall, walk with a roller for full pressing. On top of the insulator is the installation of interior decoration.

- This method is used only when specialized surface insulation is not possible. Styrofoam plates need to be laid one to one, without gaps.

- After gluing the foam, you need to do a vapor barrier. This is a prerequisite when similar work is carried out on the internal surfaces. Next, the installation of vapor barrier is completed, begin wall decoration.

We insulate with plaster

Walls made of bricks may be insulated with plaster mix.

It happens as follows:

- Initially, a fabric or metal grating should be applied to the surface. The stucco mixture must be at least three layers.

- The first layer is made by spraying and rubbing, so that the mixture could get into all the holes and glades that are present.

- This procedure requires a thin cement mixture. For this action, use a paint brush and a tenacious brush.

- The layer thickness should not exceed 5 millimeters. The next layer is a primer. This is the most significant heat-insulating layer, it must be applied with a spatula gradually. The thickness of the soil is 50 millimeters.

Attention: It is necessary to apply the soil a little bit so that it would not crumble without sustaining its weight.

Mineral wool wall insulation

Basically, this is done by warming the brick walls of the bath from the inside. This material does not cause problems in work; if necessary, it can bend and “break”, which, in turn, is not accessible to foam.

The only requirement: cotton wool is not cut with scissors, because when pressed down, it loses its purpose. The procedure for conducting mineral wool insulation works is much like installing a thermal insulation using foam.

Mineral wool must be introduced into the area among the blocks in such a way that there would be no gaps between the plates. First, the installation of waterproofing is carried out, subsequently the assembly of accessories of the heat-insulating layer, the vapor barrier is attached in the same way to the blocks.

Attention: Surfaces under cotton wool are preferable to plaster. It is allowed not to plaster, but to create a frame of wooden blocks on a brick wall, and put a heater between them, but then you need to use a thicker insulation. Caution: For cutting, it is preferable to use a sharp knife or saw. By adjusting the parameters of the slabs, it is necessary not to cut 2 cm each, to leave a margin so that the insulator fits snugly in the right places.

- Insulation of mineral wool wall made of brick from the middle, as well as in the case of polystyrene foam, requires a frame, which will subsequently be treated with sheets of drywall boards, or something else.

- The frame is the same as for the foam, it also lays insulation in the level of the lattice. So that cotton wool does not lose its properties, do not ram it. You can apply the frame from the metal profile.

- Wall profiles should be fastened 60 cm from each other so that the drywall layer, 120 cm wide, covers 2 parts without partitions. On top is a layer of waterproofing.

- After, each part is filled with cotton in two layers, according to the size of the insulation. A vapor insulator is placed on the cotton with a foil side in the middle of the room. Both insulators are attached to the frame.

- Further, the base is hidden by drywall or other raw materials that develop the design of your environment.

Insulation of a brick wall from the inside is not a difficult thing, but a responsible one. The instructions will help you do everything right and avoid mistakes.