How is foam plastering done?

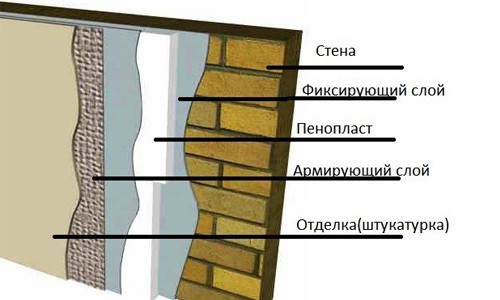

Styrofoam for plastering is not always done, but in many cases this will be the most optimal solution to the facing problem. Indeed, in this embodiment, you do not need to make the surface larger in volume with the help of a lattice.

How to plaster polystyrene correctly, we will consider today. Also in the video in this article you can see the most difficult areas of work.

The content of the article

What is the role of plaster

Plaster is a time-tested finishing material that has gained popularity for a number of its properties.

The application of plaster on the foam performs the following functions:

- Protects foam from mechanical damage. Probably everyone knows that polystyrene is a very fragile material: you just have to lean on it, as soon as a dent appears. And if you hit, then you get a hole. Thus, the plaster will be an additional outer layer, a barrier that can protect the foam from numerous damage.

- It protects the insulation from the effects of ultraviolet rays that are harmful to it. Ultraviolet radiation is a serious problem for polystyrene foam. A layer of plaster hides the material underneath, thereby preventing ultraviolet radiation from entering its surface.

- Provides fire safety. Polyfoam belongs to the class of combustible materials, plaster, on the contrary, is not subject to burning. In this case, the plaster will act as a shield, a barrier to the path of fire, preventing its penetration, causing the foam to ignite.

- Protects from moisture. Although the foam is characterized by a low degree of moisture absorption, but if suddenly the insulation gets very wet, then it will dry for a rather long period of time. Constantly high humidity, dampness around lead to a loss of material properties, making it even more brittle, brittle.

- Brings gloss to the walls, giving them a presentable, aesthetic look. Using plaster, the surface becomes perfectly flat.

Do-it-yourself plastering

How to properly plaster polystyrene video will show you the correctness of the work. The coating price is not high and therefore it is often used. All work is done in several stages, which must be maintained in sequence.

Caution: In the work it is better to use mixtures of trusted manufacturers or do it yourself. This will be the key to the longevity of the coating.

We collect material and tools

Application of decorative bark beetle plaster on polystyrene foam and any other is done with the right tool. He will help to do everything efficiently.

You will need:

- Capacity for mixing the solution;

- Mesh;

- Putty knife;

- Stucco mesh;

- Drill with a nozzle;

- Emery cloth;

- Plastic grater;

- Roller;

- Large-pore sponge or grater with a special canvas to create a texture;

- Dry plaster mix;

- Primer;

- Decorative plaster.

This is the entire list of what is required when applying plaster.

We prepare the surface for work

Do-it-yourself stucco plaster is applied to the prepared plane. This will ensure the quality of the coating and its durability.

What distinguishes the walls finished with polystyrene foam is their evenness, therefore, any additional work on smoothing, leveling is not required. But you should pay attention to the following points:

- Stitches. There may be unfilled areas. Joints that are not tightly adjacent to each other, the gaps between them must be well leveled, filled with mortar and allowed to dry.

- If foam escapes to the surface, excess material should be removed.

- The entire working surface is cleaned of dirt and dust.

- Making better grip. Since the surface of the foam is very smooth, the glue does not fit well on it, spreads, rolls down. To eliminate this drawback, you can use a needle roller, rolling it from top to bottom or use a hacksaw, leaving a shallow cut. Thanks to this, we will no longer have a smooth, but a porous surface. The solution, glue will linger in the pores, dry there, providing reliable fastening of the material.

Knead the solution

Many think better warm plaster or polystyrene, here the answer is one, of course the polystyrene will provide higher thermal insulation of the room. Manufacturers produce a wide range of plaster mixes, dry and ready-made.

For each type of finishing or building material a special mixture is offered. Therefore, choosing the right solution will not be difficult, just carefully study the packaging.

Stucco for foam, in turn, is divided into several types:

- Universal, used to perform any operations;

- Special, for sticking polystyrene onto the base;

- Forming a protective layer.

Since we will perform the plastering of the foam using a mesh, for this purpose the best option would be a universal mixture.

Attention: for work, purchase the required amount of a mixture of one manufacturer, one brand. Each brand has its own characteristics in the preparation of the solution, application to the wall and so on, which when mixed can give an unexpected result, affect the quality of the finished work.

- When preparing the solution, follow the manufacturer's recommendations. Everyone has an instruction.

- In general, it is convenient to work with a solution of medium density, similar to sour cream. When mixing a large volume of the mixture, use a drill with a special nozzle. Please note: knead the solution for one working cycle, for the time for which you have time to completely spend it. The diluted mixture becomes thickened over time, dries, i.e., loses its properties.

- On average, when plastering with a mesh, 4 kg per square meter is consumed. m

We lay the grid for plaster

Function grids for plastering lies in the reliable fixation of the material on the surface of the foam.

- In this case, it is preferable to choose a material intended for facade work. At the same time, density is one of the important indicators. A denser mesh ensures evenness of the plaster layer. But at the same time, excessive density complicates the process of gluing in the corners. The optimal density is 140–160 g per square meter. m

- Another indicator that you should look at when choosing a material is resistance to alkaline substances, since in a stucco mixture often one of the components is cement.

So, we start laying the grid:

- First, glue the mesh on difficult places: corner, slope, opening. To do this, cut off a strip, the width of which will be 30 cm, and the length corresponds to the length of the slope. The corner of the wall can be glued using meter sections.

- Bend the strip in half, making an effort. We well penetrate the fold line so that it is even noticeable when the strip is straightened.

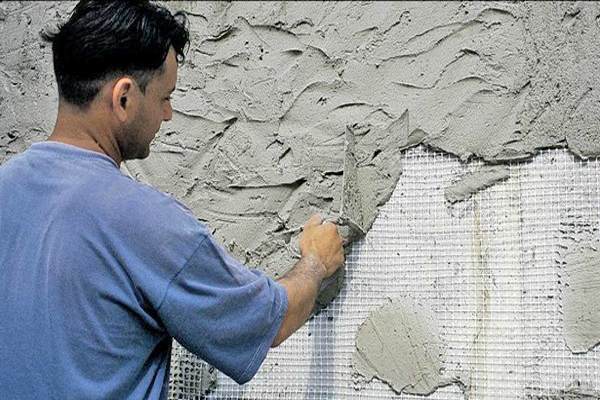

- Apply plaster to the wall using a spatula. The layer thickness must be at least 3 mm.

- We put the grid in a corner and press with a spatula. Then we perform smoothing movements in the direction from the corner to the side and down. We glue the grid with an overlap, so we leave an un glued 3 cm strip with the edge.

- Repeat these steps to process all angles and slopes.

- Getting to pasting the rest of the area.

- Cut the grid into strips. If the room is small, then we cut pieces equal in height to the room. If the surface to be treated is large, then we use meter sections.

- We take a spatula and apply the mixture to the wall, making a strip equal to the length of the cut piece of mesh, and add an additional 3 cm in width for the overlap. Layer thickness - 3 mm.

- We apply the grid and smooth it with a spatula. It should be hidden by the solution, if not, apply a little more mixture. We perform movements with a spatula in two directions: from the middle to the edge and from top to bottom.

- When gluing the mesh, we leave both edges free so that they can then be glued at the same time. When alternately applying edges, after plastering, a rough, bulging joint is obtained. It will be very difficult to hide it when finishing.

- Having finished pasting one strip, go to the other, performing the previous operations.

Grout and apply a smoothing layer.

Plaster on top of the foam applied on the grid now give the plaster time to dry and then proceed to level the wall. To do this, you will need to grout using a special plastic grater with an emery cloth on it.

- Rough alignment is carried out by a plate with large grains, ideal smoothness is obtained - by small ones. We wipe the surface, without making any effort, without pressing, in smooth circular movements counterclockwise. In the process, we change the emery cloth several times.

- After grouting, we proceed to the final leveling of the wall, resorting to using a universal mixture. But in this case, we make the solution more liquid, so it will turn out plastic, easily hide all the flaws.

To plaster a wall, we will perform the following simple steps:

- We put the plaster on the spatula and smoothly rub it on the wall.

- The layer of application of plaster will vary depending on the evenness of the surface, the quality of the first layer, grout. It will be approximately 1-3 mm.

- The leveling layer is characterized by application in the form of nickels. In this case, the coincidence of sections and joints of the grid should be avoided. Leave the solution to dry, but not allowing it to dry out, since then it will be difficult to wipe. The optimal time to start grouting after the leveling layer is one day.

- Next, grout in the manner described above. We try to perform grouting efficiently, resulting in a perfectly smooth surface.

Apply primer and finish

To achieve maximum adhesion of the finish and surface allows the applied primer layer. The primer is a special solution that is applied to the wall using a short-nosed roller.

Attention: When droplets, drips appear, shade them immediately. The primed wall is left to dry.

The last step in performing work on plaster is to apply a finish layer, which is given a certain texture, and color is selected.

This step consists of the following actions:

- Using a spatula, apply the mixture evenly to the wall.

- Using a sponge or grater, we form a texture, while the solution is applied to a small area, give the texture and proceed to the next. So, until the entire surface is covered.

- Having finished work with decorative plaster, we leave the wall to dry.

- A dried wall is covered with a colorless composition if desired.

You now know how to plaster polystyrene foam, you just need to prepare the correct solution and make a qualitatively basic plane. This is all visible in the photo.

If you follow all the recommendations, then the coating will serve you for a long time and will not require quick repairs. Plastering the foam video will give you the opportunity to understand everything and do the right job.