We conduct insulation of the external walls of a brick house

Insulation of a brick wall outside is the most optimal. But sometimes this simply cannot be done, while the second option can be done with internal insulation. Although the effect will be lower from the first option.

Today we will consider how to insulate a brick wall from the outside and how to do it correctly. In the video in this article and photo, you can and correctly choose the right option for finishing insulation.

The content of the article

What is it for

It is a natural question. The work ahead is huge, the cost is not small. Is it possible to do without extra costs? The answer is in the attic. Enough to get up and inspect. You can see from the outside. Enough in the winter, take a walk along the street.

Some houses have no icicles. It works thermal insulation. It must be understood that warming works in both directions, it does not "let in" cold air, and does not "let out" warm.

Warm streams passing through a poorly insulated ceiling heat the roof, the snow begins to melt and appears in the form of water on the edge of the roof. But the street is not zero, here is the water and turns into icicles. In such a tricky way, you can quickly assess the state of thermal insulation and make a decision.

When planning work associated with not small costs, I would like to understand what it is for and how it works?

Wall insulation, the work is quite complicated and requires a serious approach:

- It is carried out in order to ensure the preservation of heat in the house, the loss of which occurs, including due to uninsulated walls. But it is necessary to insulate other parts of the structure.

- Also, do not forget about waterproofing. If you do not, then condensation will accumulate, and this should not be allowed.

- However, you need to understand - only complex work, which includes the rest of the areas (roof, foundation, floors), can provide heat in the house (provided, of course, high-quality work is done).

- Any type of insulation (seeWe choose materials for wall insulation from the outside), in fact, is designed to neutralize the bridge of freezing (to preserve warm walls) and “transfer the dew point” (to prevent destruction of the brickwork) and in some cases, acts as a “barrier”, preventing the entry of cold air through the cracks. This is precisely the reason that the house is cool. Only with the right choice of materials, conscientious approach and quality work is the desired result achieved. Instructions on these issues will be below.

Attention: The heat engineering calculation of the brick outer wall is done according to the thickness of the material and the conductivity of the insulation. You can find this parameter in the photo above.

Type of insulation

Separating into types, it means various methods of insulation. Among the more accessible, tested and therefore - common, three can be distinguished as the main ones.

| External | This type can be used as a refinement of an already constructed building. It is done on the outside of the wall, but it has a peculiarity - the work is done seasonally, and besides, in dry weather. Despite this, it is popular among builders (but, unfortunately, not cheap). |

| Interior | It provides that the insulation is attached from the inside, i.e. inside the building (seeHow is warming a brick wall from the inside) In addition to walls, with this method, the floor is insulated, and floors between floors, as well as the ceiling (attic floor) and the roof.Convenient, because you can work at any time of the year, and in any weather. |

| Intra-wall | It is made during construction, and is part of the structure - which cannot be changed. At the time of erection of the walls, in the masonry, a distance is left unfilled, which is filled with heat-insulating material. |

What material is used for thermal insulation

Insulation of the outer brick wall with eurotizol and siding is done after fixing the insulation. It can be quite different. When choosing materials, you need to clearly know what it is chosen for. What specific functions should perform. The fact is that for various works, different material is selected.

For example, the one that for outdoor work may not work, if you use it for internal work, and vice versa. Weather conditions must also be taken into account directly in the region where it is supposed to be used.

It is possible to insulate the brick wall of the apartment from the outside with many materials, but you must consider the following:

- Destination by type;

- Resistance to temperatures and their changes;

- The ability to maintain the quality of moisture;

- Responsible for the qualities necessary for decoration (exactly the one that is planned).

To insulate a brick wall outside, use a number of materials:

| Mineral wool | Suitable for work if the facade is decided to be made “ventilated”. (between insulation and casing, air has free circulation. For more humid areas. Provides drying). But gradually, it becomes worthless, just because of frequent wetting. (It can be used with internal insulation). |

| Styrofoam | Less prone to the effects of getting wet. For outdoor work - just right, but you need to consider - the material is easy to break. It will take protection from external influences. When you purchase it, you must specify - the thickness and density, taking into account weather conditions. |

| Expanded clay | It is rarely used for external or internal insulation. Most often for the wall, or for the foundation, sometimes for the base. He is not expensive, not difficult to work with. It is done simply - it is poured into the space between the wall and the sheathing material, the distance is 20-25 cm. The disadvantage is its heterogeneity. |

| Warm plaster | It does not require special skills, easy to work. It is applied on a foam base, the layer is not large, usually 1 cm. (Determined depending on the type of brick) It must be taken into account - a tricky thing, the lower the thermal conductivity, the greater the required layer. But - if it’s blown out somewhere, then it won’t be. In addition, the appearance - becomes respectable. There are a lot of varieties, various additives, plasticizers - make such plaster a very attractive material. It can be used as plaster, and as a filling material (with formwork). The disadvantage is weight. With heavy weight - you need to strengthen the foundation. |

| Cork - as sheets | Environmentally friendly material, has good thermal conductivity, but, due to its increased combustibility, it is rarely used. Is that inside. 6. Eco-wool - not expensive, and you can lay it using both the “dry” and the “wet” methods. But experts recommend using it indoors. |

| Eco cotton wool | It is not expensive, and you can lay it using both the “dry” and the “wet” methods. But experts recommend using it indoors. |

Attention: Thus, we can conclude: the most suitable material, in this case, is either mineral wool or a “warm wall” coating with a foam backing.

Brick wall insulation

How to insulate a brick wall from the outside we will consider in stages. When insulating the walls from the outside, insulation of the base and protruding walls of the foundation is also carried out.

Before starting work, the object is inspected in order to detect damage. It is necessary to eliminate them before the start of the main work.This may be the formation of cracks, chips or the absence of any parts. After the wall is aligned, it must be dried and sanded.

Having covered the wall with a primer, you can start laying the foam. There are two ways to do this: “plant” on the glue (in structure and outwardly, it resembles a cement mortar) or fastens with dowels (special, long with a fungus cap) or “umbrella”.

The work is performed in the following order:

- The glue is applied to the insulation plate, and to the wall, (the layer should not be thick). Spreading evenly over the surface of the slab, make sure that the edges are filled with mortar.

- Pressing it firmly against the wall, you need to make sure that it stands up straight, then repeat the same with the second plate.

- Laying, in structure, resembles tile laying, in that the front part is aligned with the wall and other plates, and the brick, by the method of “running” seams (checkerboard order).

- Thus, starting from the bottom, there is a laying at the top, row after row.

The option of combining fasteners (glue and dowels) is also possible. In this case, the adhesive is applied less, and the dowels are distributed at five points, in the corners and in the middle, indented from the edge of 10 cm. A mesh is attached to the reinforced wall to reinforce the finishing layer of the plaster.

Important: make sure that the edges of the plate are filled with glue, in order to avoid moisture.

A prerequisite, as well, is not to fit the slab into a tight one to the other, but leave a small gap. This is done, due to the nature of the material.

The fact is that when the temperature regime changes, from plus to minus and vice versa, polystyrene, like other materials of this quality, expands and narrows (breathes). The result is a “hump” in the center, and this, in turn, leads to a “coloring” of the plaster.

Tool and material to be prepared:

- Heat insulator;

- Plaster for leveling walls;

- Stucco for finishing;

- Mesh, for reinforcing the finish layer;

- Dowels, glue for fastening plates;

- Putty knife;

- Tanks for mixing mixtures;

- Level;

- Knife (for polystyrene foam);

- Grater (for leveling plaster);

- Hammer drill.

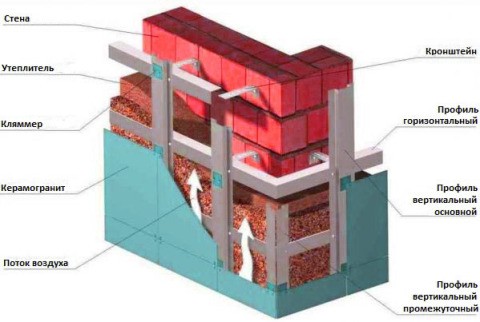

Ventilated facades

This type of insulation is designed, first of all, to ensure the safety of the insulation, which can suffer from moisture. But this may not be enough if measures are not taken to prevent water from entering. Protection, acts as a waterproofing film.

Attention: When using this method, it is possible to put into operation a material that is afraid of water (mineral wool), but it is recommended, nevertheless, to use a safer material (in terms of getting wet).

Dividing the work into stages, the following order is obtained:

- On a previously prepared wall, a vapor barrier film is attached. It is attached using double-sided tape to the wall. They start from the bottom, and row after row, horizontally, rise to the top. It is necessary to line 10 cm with an overlap. The joints should be glued with double-sided tape.

- On top of the film, the bars are attached vertically (using dowels). The step is determined by the width of the insulation boards, so that they enter between the bars, but tightly. At the same time, the bar should not be thinner than the insulation. In cases where the thickness of the insulation implies laying in two layers, you should remember the rule of “checkerboard”, and not allow the seam to be sealed on the seam.

- Using a stapler, we fix the waterproofing film. The order is the same, 10 cm overlap from top to bottom. Glue joints.

- On the bars, through the film, brackets are installed, a guide profile to them. Further installation is carried out in accordance with the design features.

Ventilated Facade System

The best option, of course, is to remove the roof. But there is an option in which you can do without radical measures. One condition is still there: under the roofing iron (or slate), there is waterproofing.If it is in place, you can begin the preparatory work.

- Preparation in this case includes mainly cleaning. It is also necessary to remove excess nails from rafters, hammered pieces of wood and various devices. In general, nothing superfluous should remain.

- Getting started, we start with isolation. With the help of a stapler, the film is attached directly to the rafters. According to the familiar pattern - from bottom to top, it will overwhelm 10 cm. Glue the joints. But you need to take into account - the insulation must "stand" between the rafters, therefore we also make the film with an allowance, but it is important not to overdo it, there should be a distance between the insulation and the roof.

- The insulation must be laid so that it tightly "stands" between the rafters. In this case, you can use any material that is available.

- The film is the second layer, nailed the same way - with a stapler. Glue the remaining edges so that it turns out continuously, with one carpet (slopes, foreheads, put together with double-sided tape). On top of the film, the crate is made.

- Overlapping is done on the same principle. Film. The crate, according to the size of the insulation plates, the insulation itself, again the film. The floor can be made temporary, from the boards, by the type of lathing. The film must be glued. From the walls, connect to the floor with an overlap of 10 cm. Connection seams on adhesive tape. It is necessary to achieve a single "cocoon".

- Ventilation is done, in this case, to equalize the temperature. No special calculations are needed; it is enough to build dormers.

Important: The hatch, exit to the attic, should also be brought into line with the work done. - Under the roofing material, air should “walk”. To do this, make "vents" in the binder of the cornice and foot arches on the "ridge".

At first glance, it may seem - there is a lot of work, and indeed doubts. It is worth trying this: remember this a little later, no matter how it was on a winter evening, after a difficult but successful day, sitting in a comfortable chair. I assure you that there will be no doubt. Warming the external walls of a brick house will save heat and at the same time make a comfortable environment in the room. And if you do everything yourself, then the price will be acceptable.