How to properly insulate a wall with a foam tile

Insulating the wall with foam during masonry is completely realistic. Polyfoam - gas-filled plastic of white color, having a small weight and low density. It has a sufficiently high-quality sound-absorbing and insulating characteristics. The advantages can also include a relatively low cost.

Installation of the structure is quite simple, but time-consuming, although everything can be done with your own hands. It is on this topic that our article will be. Also in the video in this article and photo you can see the most difficult moments of this work.

The content of the article

Polystyrene insulation rules

How to insulate the walls with polystyrene foam now, we will analyze the points. The price of the material is not large and everyone can afford this type of insulation. Below is an instruction on the rules and features of this work.

Preparation of work

Before starting the installation, it is necessary to verify the reliability of the structures and eliminate all visible defects, and only then proceed with the installation.

First you need to visually inspect the wall for visible defects or damage (cracks (see How to repair cracks in brick walls), voids, traces of wiring). The wall should be flat - the allowable difference in level is allowed no more than 5 centimeters.

Polyfoam material is quite flexible - but a larger difference will not contribute to the formation of a flat surface. In addition, replace the window and door openings whenever possible.

The process of warming itself is conditionally divided into the following stages:

- Cleansed space from construction and household wasteprovides unhindered access to the structure. If the work will be carried out at a height, scaffolding is prepared (according to pre-drawn templates, taking into account the height of the structure being processed). There is a procurement of all the materials that will be needed in the work process.

- We carry out a primer of walls. Depending on the material that was used in the construction of the walls, choose a primer mixture. Acrylic primer is usually used for concrete walls. Mineral primer for brick, and alkyd-based primers treat metal and wooden surfaces. A roller or spray gun is usually used as the application tool.

- Now it will be possible install plaster beacons. They will make it possible to do everything in one plane. They are used in order to level out wall deviations as much as possible, in order to give a more even surface. Chopping cords are pulled from opposite corners of the wall, given the indent from the trimmed plane (equal to the thickness of the insulation + adhesive solution). Further, the installation process consists in the sequential laying of all the necessary layers of insulation material.

- Now the adhesive solution is done. To make full use of all the capabilities of the foam (insulation and sound-absorbing material), it must be firmly fixed to the wall. Therefore, do not underestimate the importance of the proper preparation of the adhesive solution. Although this operation is simple, it still requires a little persistence. Stir glue and water thoroughly following the instructions. Achieve a uniform, lump-free adhesive composition.

Warming of slopes and window sills

The second stage of work involves the installation of window sills and insulation of slopes.

The window sill must be taken out for the prepared wall at a distance of 3 - 4 centimeters, while the subsequent wall insulation (the thickness of the foam is 1-2 cm) must be taken into account. In addition, external slopes are insulated, using polystyrene with a thickness of 3 - 4 centimeters.

Attention: the slope insulation must extend 1 cm beyond the wall, this is used for the convenience of joining the slope insulation with the main wall insulation.

When attaching, do not forget to carefully putty the joints.

Installation of insulation material

It is possible to warm the wall with foam without bark beetle without problems. As a rule, this operation is performed in dry, calm weather, which will give the most efficient bonding of the adhesive solution.

Warming is carried out after installing the crate. It can be made from a metal profile or wooden beam. How to properly insulate the walls with polystyrene will now be considered in detail.

Attention: If you use timber as a lathing, then before installation it must be treated with antiseptics and this will significantly extend the life of the wood.

Using a building comb, an adhesive solution is applied to the foam fragment, and if possible, the entire area of the selected fragment is covered. In addition, an adhesive solution is applied to a pre-treated wall in 0.5 meter increments with small tubercles. It is also used to level surface irregularities.

The foam fragments themselves must be glued, taking into account the recommendations of specialists:

- Plate planes must be set on pre-set base beacons

- Provide an adhesive solution around the perimeter of the foam fragment, this will allow you to squeeze the insulation more tightly and to avoid the formation of gaps

- If gaps still formed, experts recommend filling the formed space with mounting foam, especially for gaps of more than 1 centimeter

- To ensure structural strength When laying the second row, consider the location of the seams of the first. Avoid overlapping fragments by applying offset.

- In the corners of the structure and places of installation of slopes lap for better docking of adjoining wall panels

Following the above recommendations, all the necessary surfaces of the house are glued. In this case, it is worth considering the location of especially cold walls in the house.

It is possible to use foam with a thicker width. The adhesive solution, depending on the manufacturer and the presence of fresh air, solidifies within 1 to 3 days. Subsequent steps may only be performed after solidification.

Attention: Now you understand how to glue polystyrene waste and insulate walls; for this, in principle, any adhesive composition is suitable. And after doing your work, the waste foam may practically not remain.

Many people think how to insulate wooden walls with foam, this is done exactly as described below. Just for mounting to the wall, parachutes are not used mainly, but simple slate nails are simply taken.

Fixation of a heater by a mechanical method

This method is used to enhance the physical benefits that foam provides as a heater.

So:

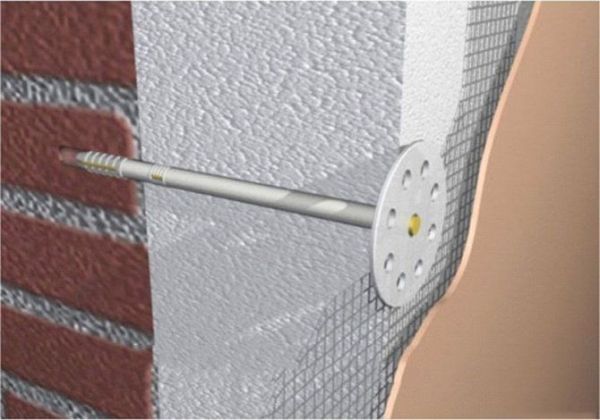

- For this, special fastening and mounting elements (mushroom-shaped dowels) are used. They are selected taking into account the inlet on the foam fragment 4 - 5 centimeters. For example: the thickness of the foam fragment used is 3 centimeters, the adhesive layer is 1 centimeter. Therefore, the length of the dowel leg 3 + 1 + 5 = 9 centimeters.

- Facade insulation is carried out according to the following scheme: in a pre-prepared installation site for mounting elements, a recess is made using a perforator, of the required length and corresponding diameter (through a fixed foam).

- Next, a mounting element is installed in the formed recess until the fungus cap is completely in contact with the foam surface. The structure is fixed using a nail, which is hammered into the technological hole of the mounting element.

Caution: Be sure to use mounting elements with metal nails, since plastic ones are easily exposed to low temperatures and can easily deform or break.

Each foam piece is fastened with 5 elements. One in each corner and in the center. In addition, it is advisable to drown the cap of the mushroom-shaped dowel into the insulation surface by 1 millimeter. Following the recommendations of specialists, you will not have problems in the installation and reliability of fixation of this design.

Grouting

To switch to reinforcement, it is necessary to wipe all the resulting seams.

- This operation is performed using a polystyrene grater or a sharp knife. The seams are rubbed so that there are no protruding corners - this will result in a qualitatively flat surface that can be used for further processing.

- It can also be done with a spatula. It is even more convenient for them to enter the composition of the seam.

- Also, specialists use mounting foam for this. At the seam, it is blown out and, after drying out, the excess is cut off with a knife.

Surface reinforcement

All seams are covered with reinforcing tape and adhesive solution. This will provide tightness and additional protection against temperature. This operation begins to produce from corners and slopes, gradually shifting to the center of the surface.

The adhesive solution is applied in a thin layer on the surface of the foam, and the mesh is pressed with a spatula. It is desirable to achieve full coverage of the mesh with adhesive solution. If the need arises, then the solution can be applied a little more.

When performing work, experts advise to adhere to the basic principles:

- Lay the tape in small areas

- It is recommended that the sections of the tape on the joints be connected to each other by applying another tape with a section of up to 5 centimeters

Work performed at the joints of foam and mesh

Carefully make a visual inspection for gaps. If gaps are found, they should be filled with foam.

- If the gap is 15-20 millimeters, then it is recommended to insert a strip of foam in the middle of the gap, followed by filling with mounting foam. After drying the foam within 3-4 hours, we cut off the residues and the foam extending beyond the surface of the insulation with a sharp knife.

- In addition, if necessary, the protruding joints are treated with a foam grater. After this, joints and mushroom-shaped dowels should be puttied with an adhesive mixture. Places where the putty sticks out, after drying, are erased with sandpaper.

- Before gluing the mesh to the wall surface, all corners are glued first. A mesh fragment is placed in the center in the corner, or a plastic reinforced corner is used. We choose a grid on the packaging of which it is recommended to use for external works. The mesh density should be around 150 grams per square meter. The higher the density of the mesh, the smoother we get the surface. It is also desirable to use a mixture for the protective layer.

Final finish

After all surfaces of the house are covered with a reinforcing stack, they grout using graters and sandpaper. This procedure is carried out only after the hardening of the adhesive solution. It takes about a day.

- The resulting surface is treated with an antifungal primer to prevent mold. Next, a layer of the leveling surface is applied, the work is much more efficient to produce with a wide spatula.

- At the final stage, they achieve aesthetic pleasure from finishing operations with plaster (see How is foam plastering done?) or mosaics. It is worth mentioning that subsequent external finishing with siding allows you to exclude an intermediate operation. Installation of panels is carried out using mushroom dowels.

Insulating the wall with polystyrene foam is a rather time-consuming operation. All stages of the work must be done especially carefully and be patient enough.

As an incentive for your work, you will get a very warm and quite noise-free room, which will allow you to significantly reduce heating costs. But it is worth remembering that in such a room it is desirable to use forced ventilation, which will avoid the formation of condensate. How to insulate walls with polystyrene foam video will help you avoid mistakes when doing work.