Facade stucco with marble chips: types, features, application methods

Today there is no problem in order to make your home stand out against the general background: for this there are many finishing materials and technologies for their installation. Each of them is more or less popular depending on climatic conditions of use, taste and financial capabilities of developers.

Facade stucco with marble chips belongs to the category of highly demanded decorative coatings, therefore it deserves a separate article.

The content of the article

Material properties and features

Like all other plaster compositions, marble plaster is a mixture of binders, fillers and modifying additives, responsible for plasticity, frost resistance and other properties. As a filler, it uses natural marble chips - hence the name.

Characteristics of Marble Plaster

The main advantages of the material are:

- High strength, resistance to mechanical and natural influences;

- Hardness and durability;

- Resistance to water and moisture;

- Good vapor permeability, which is important when creating "breathable" coatings;

- Resistance to ultraviolet rays;

- Ecological cleanliness;

- Excellent adhesion to various surfaces - brick, concrete, foam concrete, plaster, drywall, etc.

Of course, many of these advantages are realized only if the instructions for preparing the plaster, its installation and operation are strictly observed. Another important advantage of marble plaster is the diversity of its types and decorative properties.

Composition and types

Marble chips alone will not stay on the base, for this you need a binder. In this case, these are acrylic resins that give the composition elasticity, impact resistance, water resistance and other important properties.

Various additives and additives may also be present, due to which the coating does not become cracked upon drying, repels dirt, and becomes resistant to mold and fungi. And the appearance and decorativeness depend on the filler.

Note. The main requirement for it is about the same grain size: in order for the marble facade plaster to create an even and monolithic coating, the crumb must be calibrated.

The size of the filler fractions determines the purpose of the plaster. While fine-grained mixtures are used for interior decoration, larger ones are used for decorating facades.

A basement (see Finishing the basement of the house: work options) most often covered with plaster with fairly large pebbles. This is due not only to the appearance of the finished coating, but also to its weight: the larger it is, the more solid the foundation should be.

The price of the plaster, the minimum thickness of the layer, and, accordingly, the consumption per square meter depends on the size of the fractions.

| Grain | Fraction Size (mm) | Consumption per 1 m2 (kg) |

| Fine-grained | 0,2-1 | 1,5-2 |

| Medium grained | 1-3 | 2,5-3 |

| Coarse grained | 3-5 | 3-3,5 |

Note. On the packaging of the plaster may not be information about the specific size of the fraction, only an indication of belonging to a particular species.

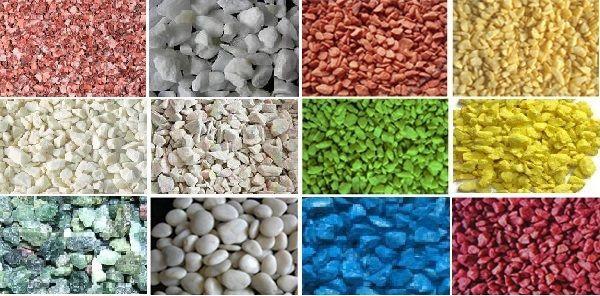

Colour

Until recently, only a crumb of natural natural color was used in the plaster, so there was no wide variety of colors. In addition, compositions from different parties could vary significantly in color due to the heterogeneity of the extracted marble layers.

Now this problem has been solved: technologies have appeared that make it possible to tint all the crumbs either in natural shades or in those that are not found in natural marble.

To do this, use only light-resistant pigments that do not fade in the sun, and after staining, the material undergoes heat treatment. As a result, the guarantee for color stability is more than 15 years for facade and more than 25 years for interior decorative plaster.

Thanks to these technologies, we got unlimited possibilities for the implementation of any design ideas. In addition to several hundred natural shades, thousands of artificial shades have now appeared, not to mention the fact that the plaster may contain multi-colored assorted crumbs.

How to finish the facade with marble plaster

It is hardly necessary to describe in detail the entire process of applying the plaster on the facade with your own hands. It consists of standard steps that have been repeatedly described on this site. But there are still some nuances, and we will tell about them.

Training

Since the weight of the plaster is impressive, the base must be prepared carefully, achieving its stability and good adhesion.

What is needed for this:

- Primarily - remove the old coating, if any.

- Next stage - carefully grout all chips, cracks and other defects with a cement mortar.

- Then - leveling the surface with conventional plaster.

Note. This step is not necessary if the walls are fairly straight, without an obvious deviation from the level. Minor defects are perfectly masked by a decorative coating. But it is advisable to plaster the brickwork, after knocking down the mortar protruding from the seams.

- Next, wait for the walls to dry. - their humidity should be no more than 5%. For the same reason, do not plaster facades in rainy or wet weather.

- The last preparatory stage Is a surface primer. It is performed with an acrylic primer of deep penetration, the composition is applied in 2-3 layers. This is necessary to prevent the penetration of moisture into the thickness of the base, to achieve its maximum strength and to minimize the risk of peeling of the heavy coating. Each layer is applied with a brush or roller only after the previous one has dried.

Tip. If the wall is not uniform in color, the primer should be tinted in a suitable tone so that spots do not shine through the plaster.

Application

Before you begin, make sure that you have enough time and material to fully finish at least one wall from corner to corner. If you take big breaks, then facade plaster with marble chips will lie in "pieces" - in bright daylight, the boundaries between areas applied at different times will be very noticeable.

There are two ways to lay the solution on the base - manual and mechanical.

- In the first case, a portion of the mixture is captured by a small spatula from the bucket and evenly distributed over the blade of the working tool - a wide spatula or trowel, after which it is rubbed against the wall with little effort. The thickness of the layer should not exceed 1.5 diameters of the largest fractions of crumbs in the composition of the plaster.

- For mechanical application, a pneumatic crusher is used, the nozzle of which is placed at a distance of about half a meter from the wall and a solution is poured onto it, moving from top to bottom. Immediately after spraying, the solution is smoothed with a spatula or other convenient tool.

After the plaster dries, the surface is completely wiped with a metal grater, and then, to achieve greater strength, the coatings are coated with a thin layer of a special varnish.

Tip. You can practice the application technique on small sections of the facade - niches, window and door slopes, decorative elements.

Conclusion

In practice, plastering facades with marble chips is even simpler than using conventional plastering - there is no need to ensure that everything is perfectly even. The structure of the composition is such that it visually masks minor imperfections. You can see for yourself by watching the video in this article.

The higher cost of the material also cannot be a serious obstacle to its use. It is compensated by the durability of the coating and the absence of the need for additional finishing - applying texture and painting.