Facade stucco for aerated concrete: how to choose the composition and apply correctly

Aerated concrete blocks for the construction of houses are becoming more popular: they are light, even, hold heat well due to the porous structure. But their high vapor permeability imposes serious restrictions on the choice of finishing materials and the technology for their use.

In particular, before plastering aerated concrete from the outside, you need to finish all the “wet” internal work, choose the right composition and calculate the thickness of its application. More on all this will be discussed in the article.

The content of the article

Features of aerated concrete and its decoration

In its composition, aerated concrete is similar to ordinary concrete: it includes cement, sand, lime and water. But the addition of aluminum powder, which is a blowing agent, gives it a specific porous structure. Moreover, unlike foam concrete, the pores are open, which increases the vapor permeability of the material.

Open pores on the surface of building blocks cannot be left without finishing for many reasons.

For instance:

- Exposure to precipitation. Wetting the outer layer reduces the thermal insulation properties of the walls, leads to cracks on the surface and even their destruction when exposed to temperature changes;

- Settling of airborne dust. It, like rainwater, has an acidic character, and prolonged exposure to an acidic environment causes darkening of the surface and leads to a deterioration in the appearance of the blocks.

That is why the instruction requires a mandatory external decoration of such surfaces. It can be performed in many ways, including the installation of ventilated facades, brick cladding with a ventilation gap, etc.

But most often, special facade plasters for aerated concrete are used for protective and decorative finishes. Its main purpose is to protect the walls from the above factors, but the coating should not reduce their vapor permeability, preventing the diffusion of water vapor from the inside out.

Note. Decorative coatings must meet the same requirement, therefore, film-forming paints for finishing such facades are not used.

Specifically, the brands of such plaster will be described below, and now it is necessary to emphasize such an important point as the requirements for the choice of time for applying the exterior finish.

It should be performed only after:

- Building shrinkage;

- Completion of the interior decoration associated with the "wet processes": floor screed device, plaster and putty wallsleveling ceilings, painting, etc. The fact is that the solutions used in this solution contain a lot of water, which, during their drying, evaporates and is removed, including through the pores of aerated concrete. If you do it yourself to block the way with a layer of external plaster, it will accumulate in the material, which will lead to the loss of its properties and peeling of the external finish.

Compositions for aerated concrete plaster

Like all other similar mixtures, facade stucco is also made on mineral (seeMineral facade plaster: material features), and on a polymer basis.

Mineral Mixtures

Light mineral plasters are used to decorate walls made of aerated concrete and gas silicate, in which instead of ordinary sand, perlite or other porous and lightweight filler is added. Such a composition is lightweight, does not exert a large load on the base and has increased vapor permeability.

Many manufacturers produce such plaster.

We list the most popular brands:

- Founces Startwell T-21. Cement-lime mixture, suitable for both outdoor and indoor use. It is applied manually or mechanically (see Machine plaster: how to do it right).

- Kraps Extra Light. Cement-lime mixture with fine-grained sand and special additives for machine and manual application on facades, internal walls, ceilings.

Note. When Antifreeze is added to the Kreps solution, an antifrosty additive of the same brand, it can be applied at an ambient temperature of minus 10 degrees.

- Plitonite T1 and Plitonite T. The first composition is designed for sealing joints and rough alignment of surfaces, has a maximum filler size of 2.5 mm, is applied with a thickness of up to 30 mm. The second is a thin-layer leveling plaster with a maximum fraction of 0.63 mm and a permissible layer thickness of 10 mm.

- Baumit ArtoPlast (Austria). Thin-layer cement facade plaster for aerated concrete and cellular concrete. It is also used for fastening reinforcing fiberglass mesh on the leveling base.

- Baumit GrundPutz Leicht. Lightweight lime-cement plaster with aggregate that improves the thermal insulation properties of the facades.

Polymer blends

Many compositions based on acrylic resins are suitable for aerated concrete plastering, as they have good vapor permeability. But silicone can also boast similar properties (see.Silicone plaster: material features) and silicate mixtures, which can also be used as a finishing decorative coating. The leader in their production is the Austrian company BAUMIT.

Among the most popular, the following ready-to-use formulations can be distinguished:

- Baumit SilikatTop is a silicate plaster with a textured or rough surface, high vapor permeability and resistance to weathering.

- Baumit SilikonTop - silicone plaster with a textured or rough surface, normal vapor permeability and weather resistance. It has dirt-repellent properties and is easy to clean.

Note. The price of finished polymer polymer plasters is higher than mineral plasters. But they can be tinted before application, eliminating the need for subsequent surface painting.

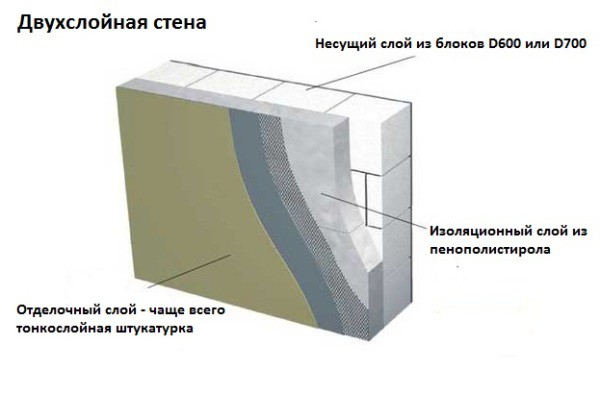

Whichever mixture you choose for exterior decoration, the following rule must be observed: the vapor permeability of the finished multi-layer “cake”, consisting of internal plaster, the wall itself and facade plaster, should increase from the inside out. It is allowed only to deviate slightly from this requirement, using materials with the same vapor permeability for adjacent layers.

Stucco Aerated Concrete Technology

It should be noted that the decoration of facades from aerated concrete, if it is carried out in accordance with all the rules, is not the fastest, easiest and cheapest operation. It consists of several stages.

Primer

Before applying a primer to the surface, it is necessary to repair all seams and cracks, to clean the surface of the walls from dust and dirt. It should be dry, and work should be performed at an ambient temperature of 10-25 degrees above zero.

The main purpose of the primer is to strengthen the base and provide its protection against moisture. Therefore, it should be suitable for use on loose and porous surfaces.Before buying, carefully study its composition, properties and purpose, the information on which is indicated on the package.

As a rule, to work on aerated concrete, hydrophobizing compositions based on siloxane acrylate are used.

Reinforcement

In order for the plaster to adhere well to the surface, a reinforcing layer is required (seeReinforcing mesh for plaster: how to apply), which uses an alkali-resistant fiberglass mesh. Resistance to alkali is a prerequisite for this material, since a plaster mortar can completely destroy it over time, which will lead to cracks and peeling of the coating. Therefore, saving on the grid is not worth it.

It is attached to the base either with self-tapping screws or glued onto a freshly applied layer of plaster. In the case when insulation and plastering of the facade of the house are made of aerated concrete, the grid is glued on top of the insulation layer.

Plaster

Exterior aerated concrete plaster is applied on the grid in the usual way. The layer thickness depends on the state of the surface and the size of the aggregate fraction. Recommended thickness is also indicated on the packaging by the manufacturer.

There are other ways of facade decoration of aerated concrete blocks. For example, if the walls are neatly folded from even blocks, it is enough to process them with a grater, rub the seams, fill in small potholes and treat with a vapor-permeable putty. It is diluted to a creamy consistency and applied to the surface using a roller or a wide brush.

You can enter a water-emulsion color in the finished solution, then the facades do not have to be painted. But it is advisable to repeat this treatment twice, allowing the first layer to dry before applying the second.

Conclusion

Having decided to plaster a house built of aerated concrete, you need to carefully approach the choice of materials. Only subject to all the above recommendations, such a finish will not worsen the properties of the walls and will last a long time.

As for the technology of applying plaster, it is described in detail in the video in this article. Carefully study it before undertaking this difficult work.