Puttying walls of aerated concrete - features of the choice of materials and work

Any building material has some disadvantages. The disadvantages of aerated concrete are the complexity of its finishing with stucco mixtures: it is believed that they do not stick to the surface, crack, peel and peel.

In fact, if you know how and how to putty aerated concrete, in what sequence to do it, then nothing like this will happen.

The content of the article

Material Information

The structure of aerated concrete is a porous capillary system. This material has a high degree of water absorption, but also excellent moisture loss, the ability to "breathe", letting water vapor and gases pass through it, and fresh air inside.

This property almost equates this material to wood. Living in aerated concrete houses is also comfortable. But only subject to proper internal and exterior decoration of aerated concrete houses.

Aerated concrete blocks leave the factory conveyor with a humidity of about 30%. But due to their special properties, after a year and a half, they dry out, and humidity drops to 4-6%.

This indicator remains unchanged if the structures are not exposed to moisture penetration into them from the outside or to its accumulation due to the passage of vapors from the inside.

Note. Increasing the moisture content of the material by 10-15% by half reduces its heat-insulating properties. Therefore, it is very important to maintain an equilibrium moisture content of 5%.

There is a special instruction on the internal and external decoration of aerated concrete buildings, which requires the use of only such building mixtures that have a vapor permeability coefficient not less than that of the wall material. Failure to comply with this requirement leads not only to a decrease in the level of comfort in the premises, but also to the rapid deterioration of the finish itself.

Why is this happening:

- If facade putty for aerated concrete does not have sufficient vapor permeability, moisture will accumulate in the structures, reducing their heat-shielding properties;

- Steam not found will increase air humidity inside the building, which can lead to mold overgrowth;

- Moisture condensing on the outer surface of the blocks under the plaster will freeze during frost, which will certainly lead to cracking and peeling of the coating.

Thus, the choice of plaster and putty mortars in our case is limited to such compositions that can protect aerated concrete from moisture, while possessing high vapor permeability and good adhesion to cellular concrete.

Finishing technology

Priority when choosing the exterior finish of walling from aerated concrete blocks is given ventilated facades and brick cladding with ventilation gap device. These types of finishes can reliably protect the walls from moisture from the outside and do not prevent the steam from escaping.

If you chose plaster or putty, and want to do the work yourself, you will find the recommendations below very useful.

Rules and procedure for work

To begin with, it is advisable to start finishing work after the completion of construction work and the building has stood for 6-12 months to complete the shrinkage process. It is even better to wait 1.5 years for the equilibrium moisture content to be established in the gas blocks.

Tip. The roof for aerated concrete houses is recommended to be made with a large extension beyond the perimeter of the walls to protect them from moisture in case of oblique rain.

Putty aerated concrete is made under the following conditions:

- The air temperature during the decoration period and a few days after it should be in the range from +5 to +25 degrees. In extreme heat, the solution will dry too quickly, causing cracks.

- Freshly plastered walls should be protected until completely dry from moisture, subzero temperatures, sunlight, strong gusts of wind.

- First, all internal “wet” work is carried out, including those related to floor finishes and the ceiling, and only after their completion can we switch to facade plastering. This condition is indispensable for fulfillment, only its observance will allow not violating the natural processes of steam removal through gas blocks into the external environment.

- Physico-technical characteristics of the finishing compounds and the base material must match.

Note. When using several plaster layers (leveling, finishing, decorative putty), their vapor permeability should also be the same, and even better - increase in the direction of the outer layer.

Inner putty

There are two options for finishing internal aerated concrete walls. The first involves their maximum vapor barrier using primers and putties that do not allow air to pass through.

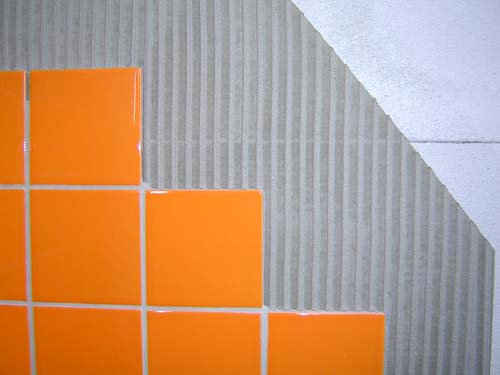

Purpose of such aerated concrete finishes consists in eliminating or reducing the flow of steam through the gas blocks to the outside, or to eliminate it by dozens of times, to eliminate its accumulation under the layer of external decoration. This is done if the outside of the house is tiled with tiles, artificial stone or other material, which limits the evaporation of moisture from the inside.

However, this is not the best solution, since the microclimate in such a house will not differ in any way from the microclimate in reinforced concrete buildings. Whereas the advantage of aerated concrete is precisely in its ability to "breathe". The price of the material is quite high, so think about whether to deprive it of its main advantages.

The second option is more preferable. It consists in the use of vapor-permeable gypsum putties. As a decorative finish, water-dispersion paints, non-woven or paper wallpapers and other “breathable” materials are recommended.

All this applies only to load-bearing walls, while the internal partitions can be finished in any other way. If there is a need for facing bearing walls with tiles (in the bathroom or in the kitchen), then it should be laid out on a limited area. For example, only in the form of a kitchen apron or plumbing areas.

Facade decoration

If the wall thickness is sufficient to maintain a normal microclimate in the house, there is no need for serious exterior decoration, it is performed only to improve the aesthetics of the building. You can simply embroider the seams and cover the walls with a water repellent with a high vapor permeability index.

If you decide to plaster, then choose the compositions recommended by the manufacturer of aerated concrete blocks. Often, he himself develops and produces building mixtures, according to their characteristics, corresponding to the base material.

Putty on aerated concrete is usually a cement-lime based compound into which various modifying additives are introduced.

It should have the following properties:

- low water absorption;

- increased vapor permeability;

- slight shrinkage;

- frost resistance;

- good adhesion (adhesion ability) to aerated concrete.

The putty layer should not be thick, therefore, before starting work, the joints are sealed and the surface is cleaned from the influx of the mortar.If the moisture content in the gas blocks has not yet reached equilibrium, then the putty is carried out on an alkali-resistant fiberglass mesh.

You can give the building the desired color with the help of facade water-dispersion paints or vapor-permeable decorative plasters. In recent years, sprayed cork has been increasingly used to decorate such houses.

This environmentally friendly material is made from cork wood chips and acrylic resins and has a high “breathable” ability and soundproofing properties.

Conclusion

To preserve the most important advantage of aerated concrete over other building materials, which is its ability to release carbon dioxide and water vapor and let oxygen into the house, use only vapor-permeable materials for decoration. Tile, stone, forming a film of paint are acceptable, but only as decorative fragments.

We recommend that you watch the video in this article, which gives more complete information on this issue.